Blast furnace roof material distributing device

A material distribution device, blast furnace technology, applied in the direction of bell and funnel arrangement, etc., can solve the problems of hydraulic oil compressibility, lower motion accuracy, harsh conditions such as lubrication and cooling, and increase the motion clearance of supporting rings and other parts, etc., to achieve motion Uniform and reliable, easy to use and maintain, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

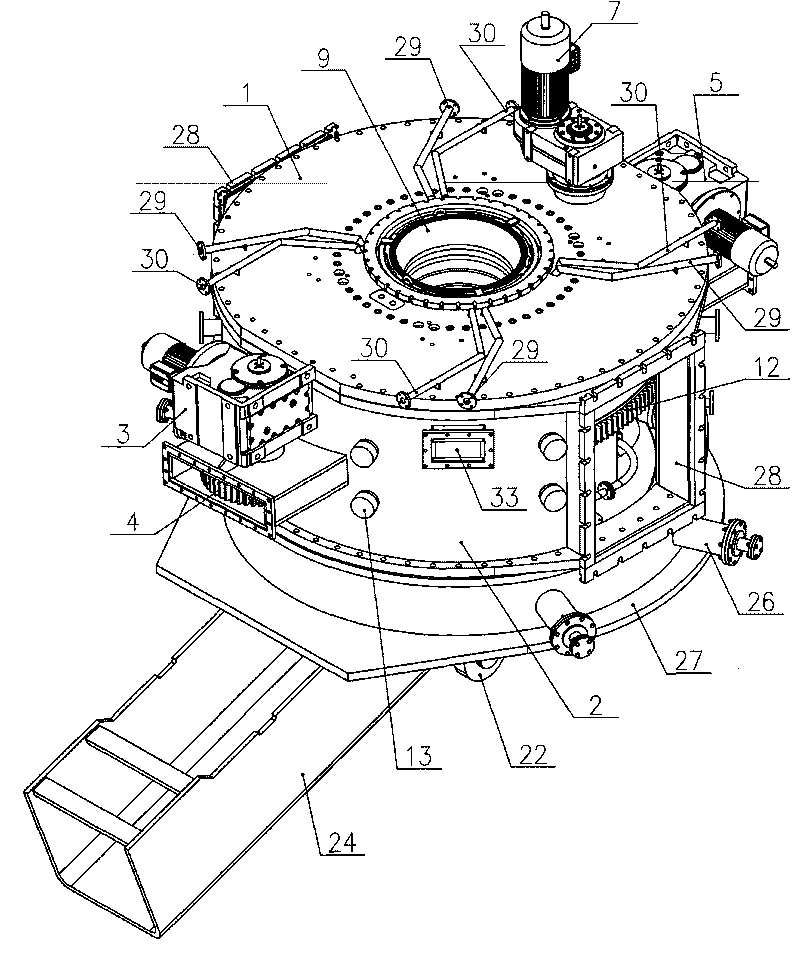

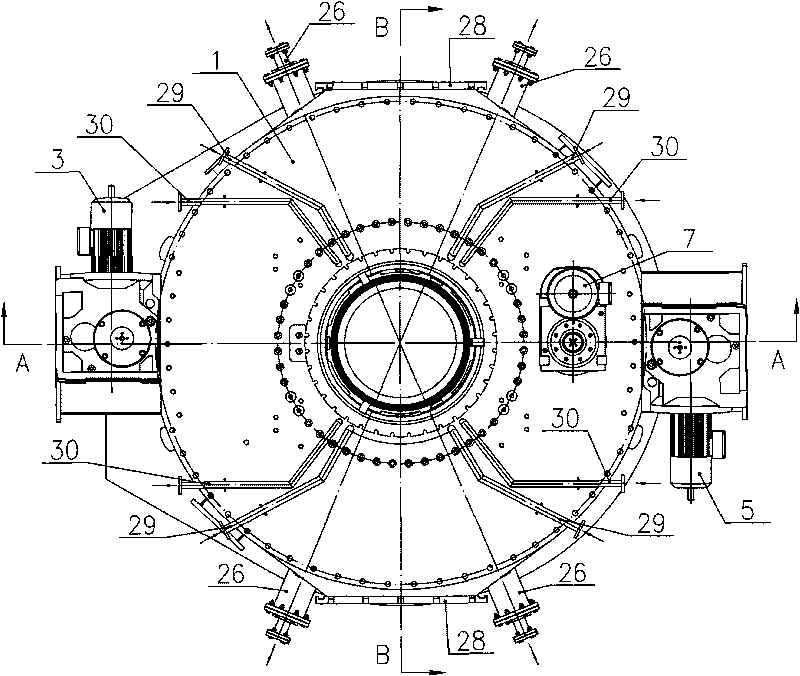

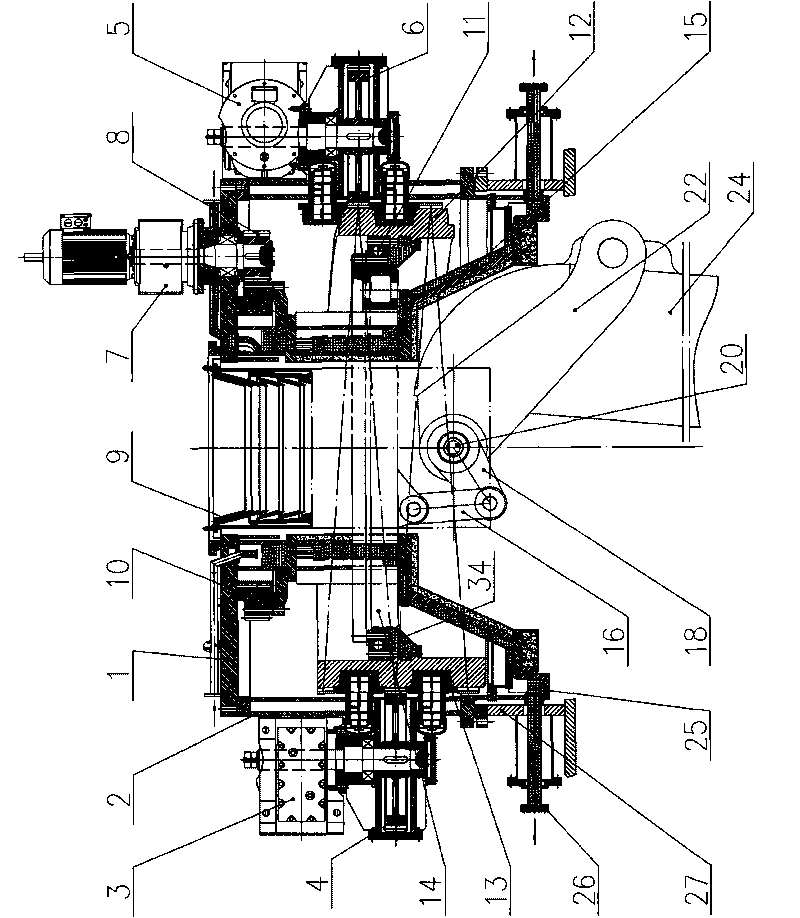

[0026] Such as figure 1 , figure 2 , image 3 , Figure 7 As shown, the blast furnace roof distributing device includes a top cover 1, a shell 2, a central throat pipe 9, a left suspension shaft 20, a right suspension shaft 21, a left swing arm 22, a right swing arm 23, a chute 24, a rotating mechanism, Tilting mechanism; the shell 2 is fixedly connected with the furnace top steel ring 27, the top cover 1 is located on the upper end of the shell 2, and the top cover 1 is fixedly connected with the shell 2; the middle part of the top cover 1 is provided with a center throat installation hole, and the center The upper end of the throat pipe 9 is located in the central throat pipe installation hole and is fixedly connected with the top cover 1, and the output port at the lower end of the central throat pipe 9 is positioned above the input port of the upper end of the chute 24 (that is, the material passing through the central throat pipe 9 can enter chute 24), the left end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com