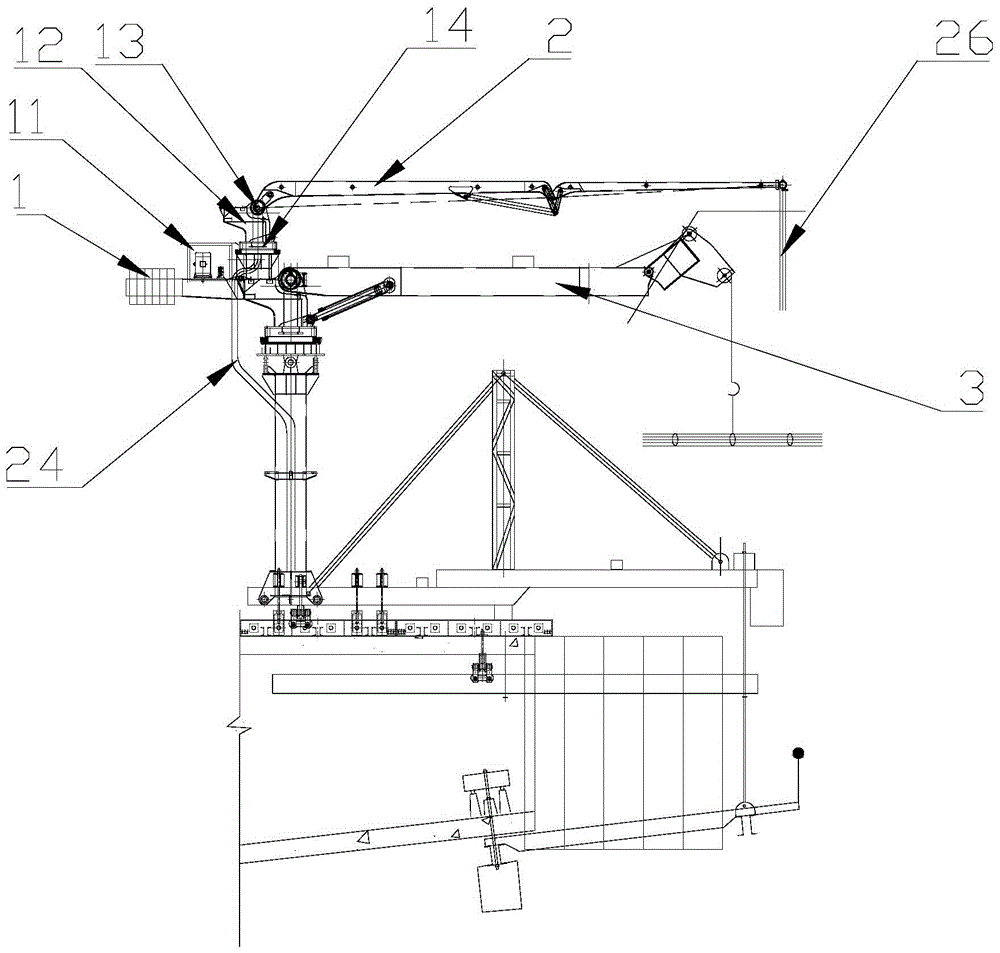

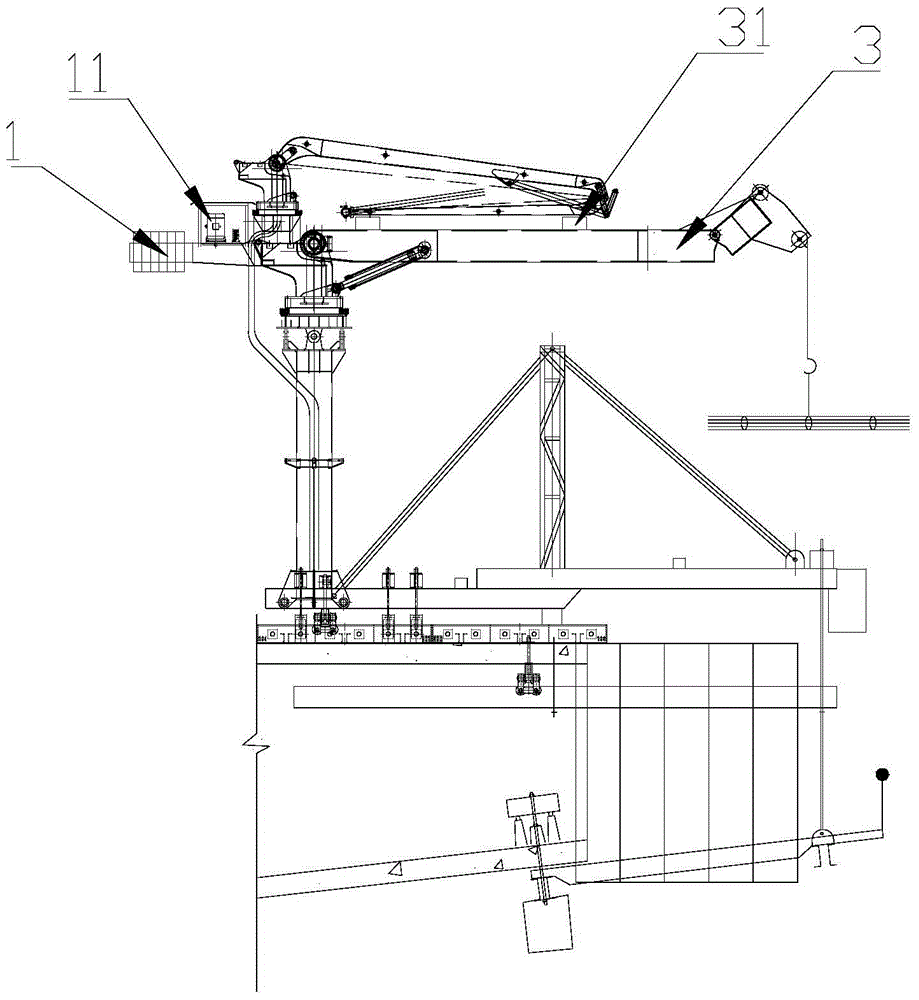

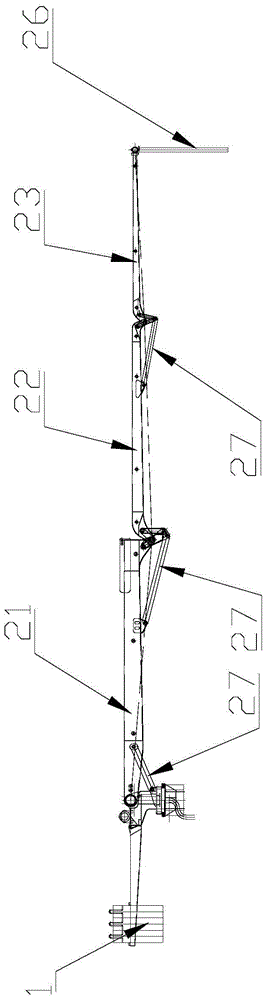

A hydraulic mobile hanging basket with functions of lifting and distributing and its construction method

A construction method and mobile technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of narrow construction site, difficult operation, and heavy conveying pipes, so as to reduce the occupied area, ensure the safety of operation, and overcome the production area narrow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0060] A. Install a new type of mobile hanging basket on the 0# block for midline and plane positioning;

[0061] B. Pre-press the hanging basket, correct the pre-camber, adjust the line shape; and check and accept the lifting equipment;

[0062] C. Control the hydraulic system to open the boom through the control system to complete the transportation of materials and small equipment;

[0063] D. Install steel bars, prestress and formwork on the hanging basket, and pass the acceptance;

[0064] E. Connect the conveying pump under the bridge with the pipeline of the hanging basket conveying system, transport the concrete to the hanging basket conveying system through the conveying pump, and send the conveying end to the pre-casting position through the lifting function to complete the concrete pouring;

[0065] F. Transport the tensioning equipment to the hanging basket through the hanging basket lifting system to complete the prestressed tensioning of the segmental box girder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com