A mobile concrete automatic distribution system

A technology of automatic material distribution and concrete, which is applied in the direction of supply devices and manufacturing tools, can solve the problems of unstable product quality of PC prefabricated concrete components, affecting the quality of construction products, unstable worker operation, etc., and achieves convenient cleaning and maintenance. The effect of high degree of automation and convenient material flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

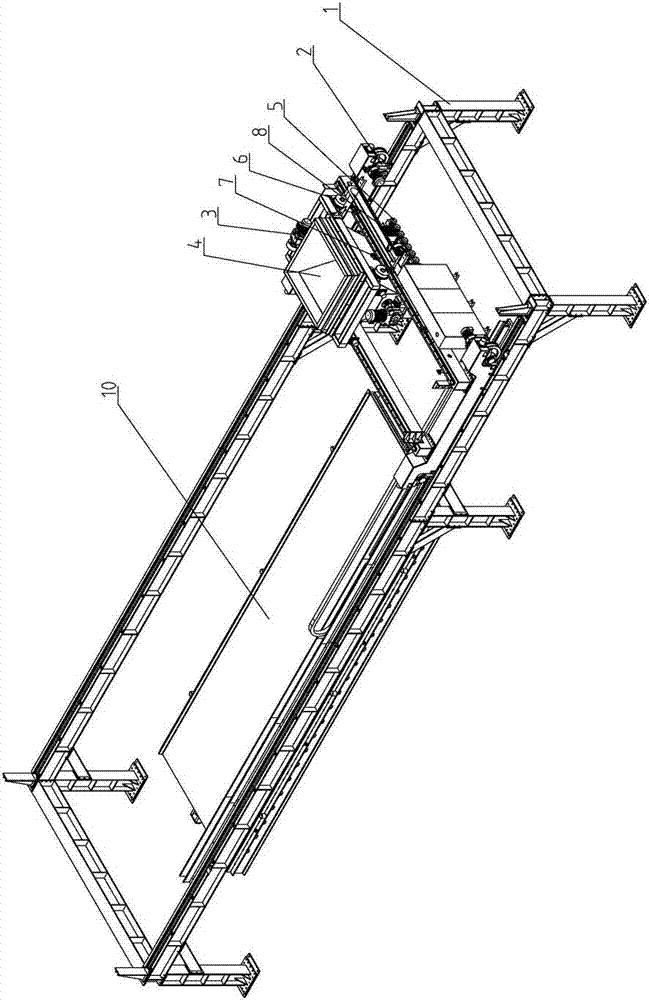

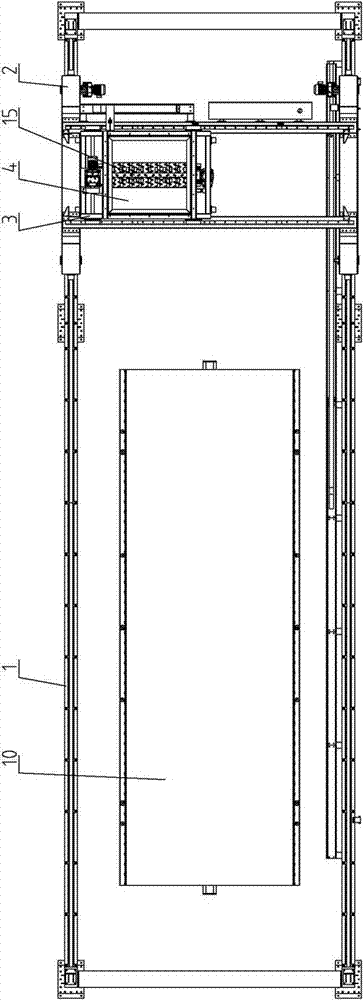

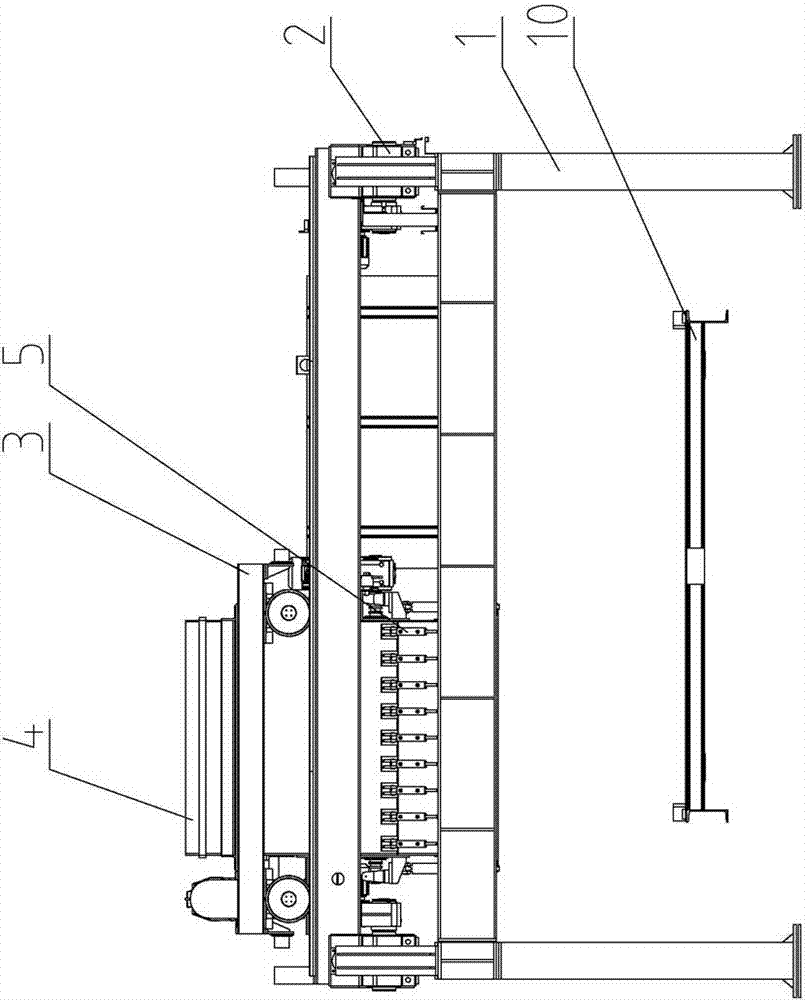

[0029] Please refer to the attached figure 1 to attach Figure 7 As shown, the present invention is a mobile concrete automatic distribution system, which consists of a frame 1, a longitudinal movement mechanism 2, a lateral movement mechanism 3, a distribution bucket 4, a distribution mechanism 5, a weighing system 6 and a hydraulic system 8. composition.

[0030] Wherein, the frame 1 is composed of columns and beams, which provide support and fixation for the whole equipment. Below the frame 1 is provided a mold table side mold system 10 .

[0031] The longitudinal movement mechanism 2 is installed on the frame 1 and can move left and right along the frame 1 . The lateral movement mechanism 3 is installed on the longitudinal movement mechanism 2 and can move forward and backward along the longitudinal movement mechanism 2 .

[0032] The distribution hopper 4 is installed on the lateral movement mechanism 3, and is linked with the lateral movement mechanism 3, and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com