Test-bed for testing performance of vibration damping belt pulley wheel

A technology of pulley and test bench, which is applied in the field of automobiles, can solve the problems of inability to detect and lack of vibration-absorbing pulley performance, and achieve the effects of simple structure, accurate performance parameters, and high running precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

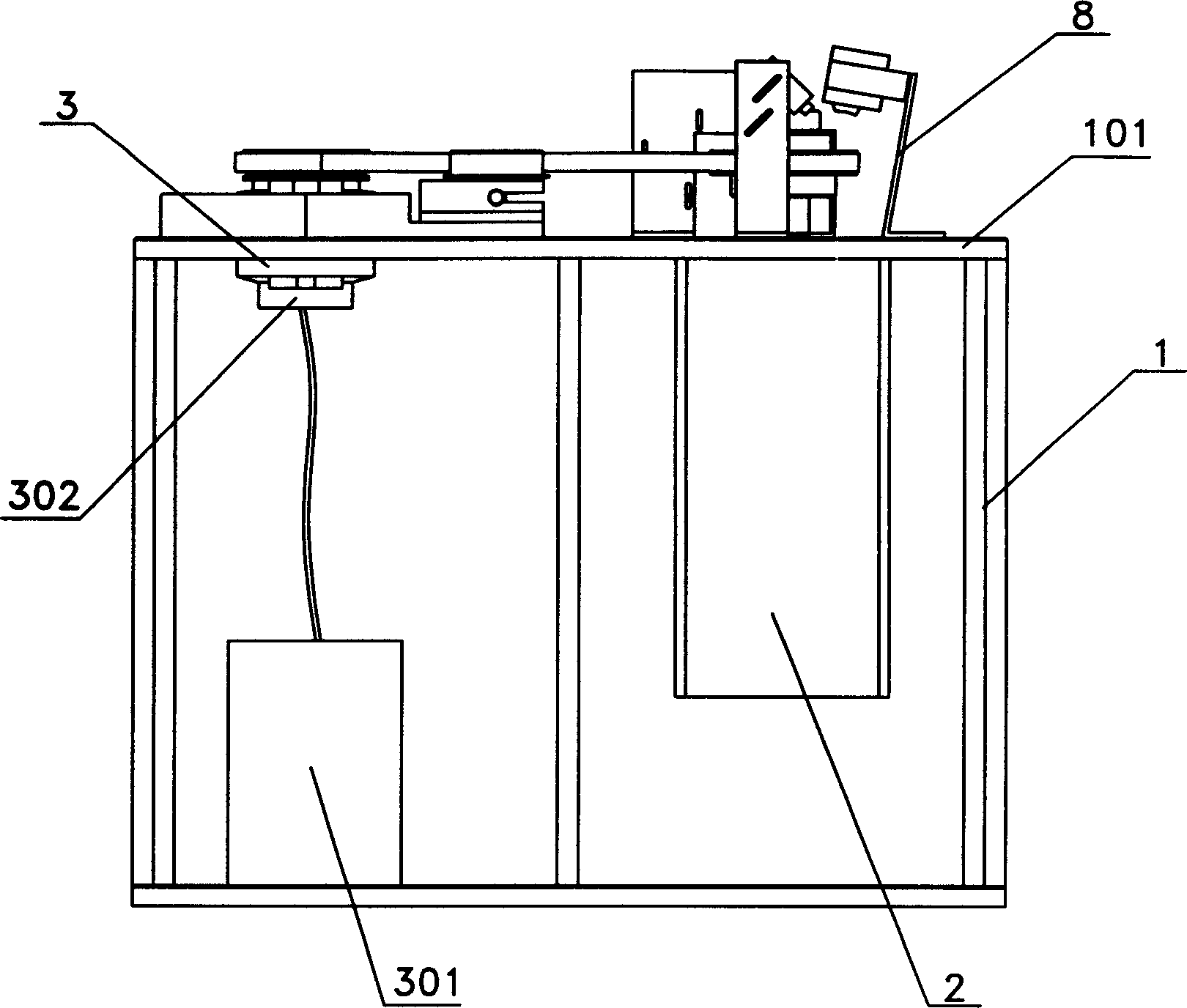

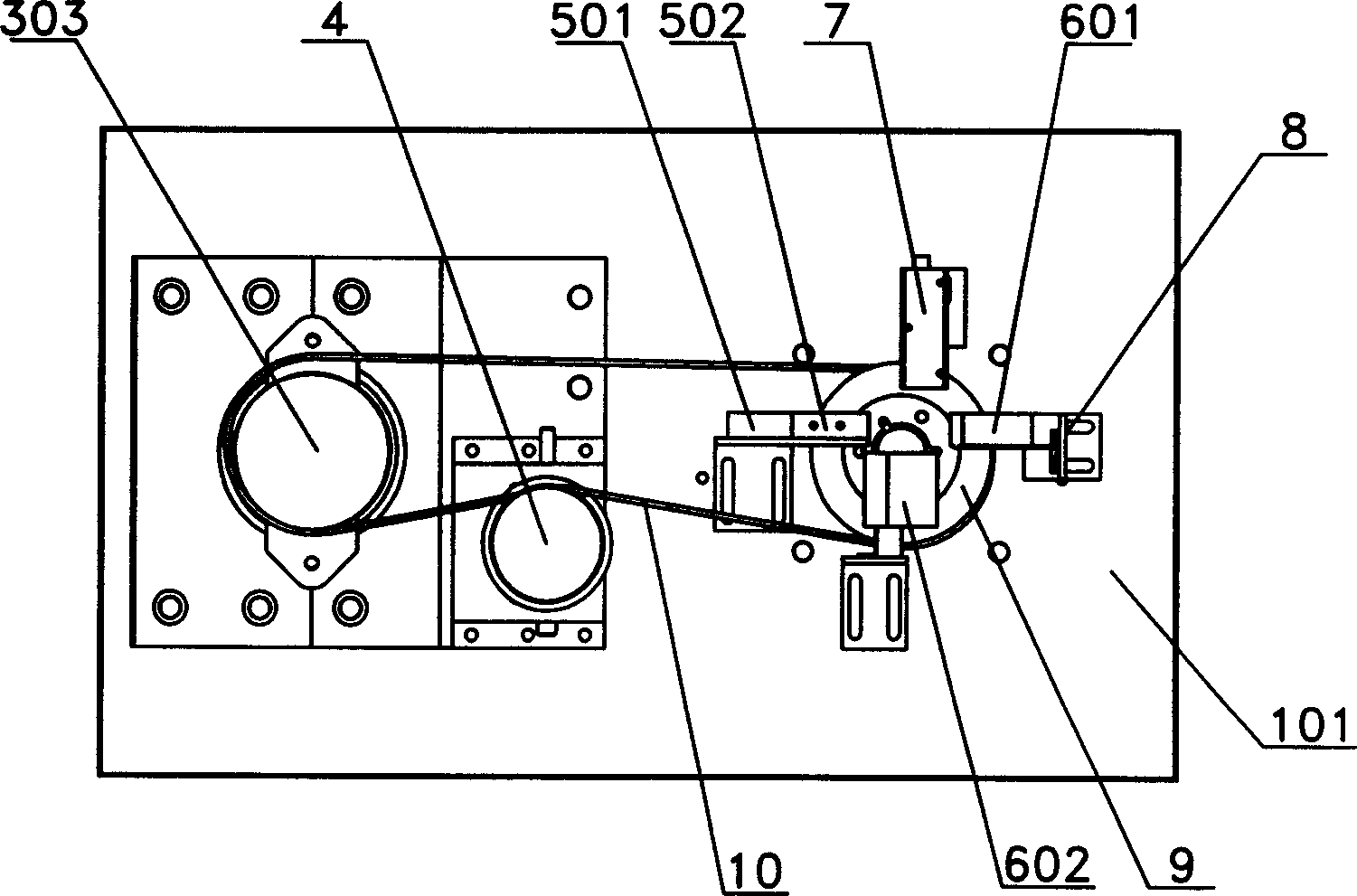

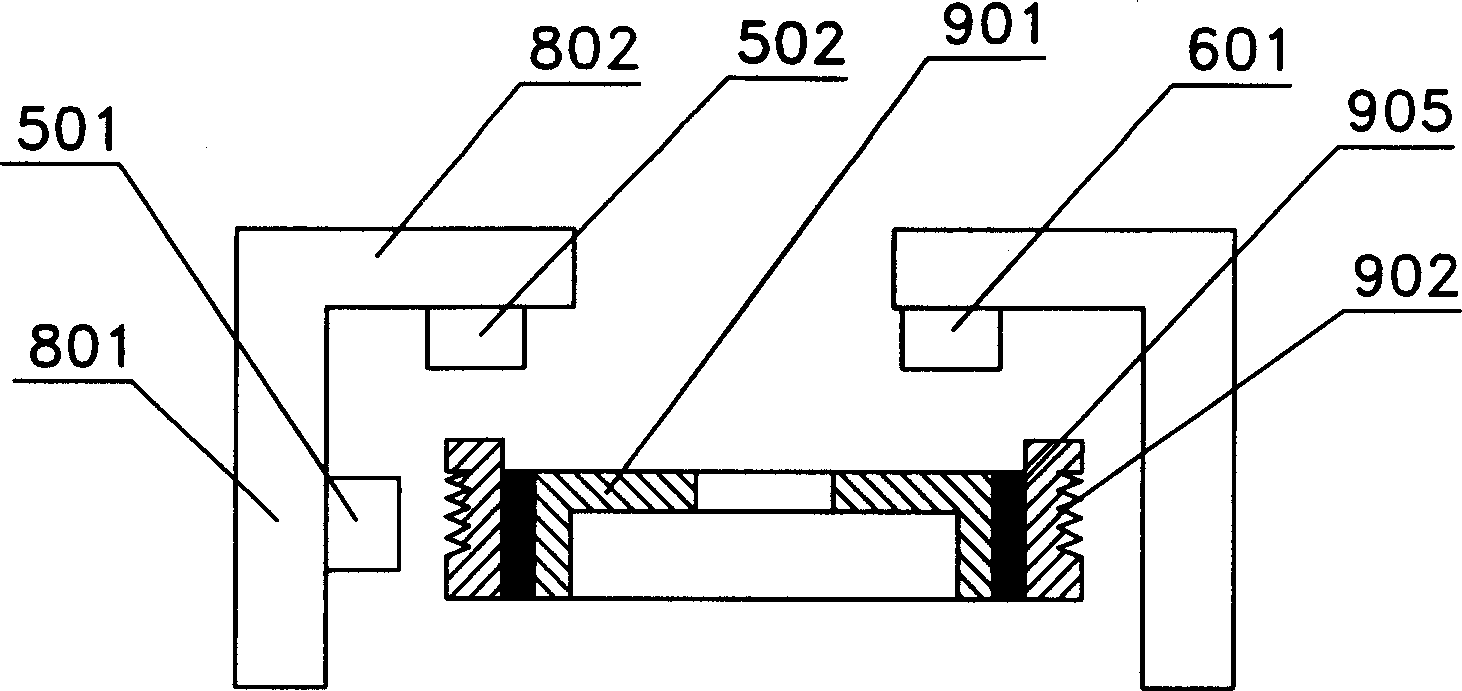

[0035] Such as figure 1 , 2 As shown, the test bench of the embodiment of the present invention includes a bench 1, a motor 2 and a tested vibration-damping pulley 9 on its shaft, a load 3 and a pulley 303 on its shaft, and a tension pulley 4. The motor 2 is a variable frequency speed regulating motor, which is controlled by a computer. The tested vibration-damping pulley 9, the pulley 303, and the tension pulley 4 form a wheel train through the belt 10. Such as Figure 5 As shown, the outer ring 902 of the tested vibration-damping pulley 9 and the wheel surface of the inner ring 901 draw a white line mark 904, 903 through the center of the tested vibration-damping pulley; The sign sensor 601 of the upper sign 903, the sign sensor 602 for sensing the sign 904 on the outer ring 902, the laser displacement sensor 501 for measuring the radial displacement of the tested vibration-damping pulley 9, the laser displacement sensor 501 for measuring the tested vibration-damping pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com