Bearing Block Device of Pulse Liquid Grease Circulation Lubrication Mode for Steel Wire Rope Stranding Machine

A technology of circulating lubrication and stranding machine, which is applied in the direction of rope-making auxiliary devices, bearing components, shafts and bearings, etc., and can solve the problem of restricting the operating speed of the tubular stranding machine, the leakage and splash of liquid lubricating oil, and the difficulty in controlling liquid lubrication Oil and other problems, to achieve the effect of good cooling effect, low noise, large oil return channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

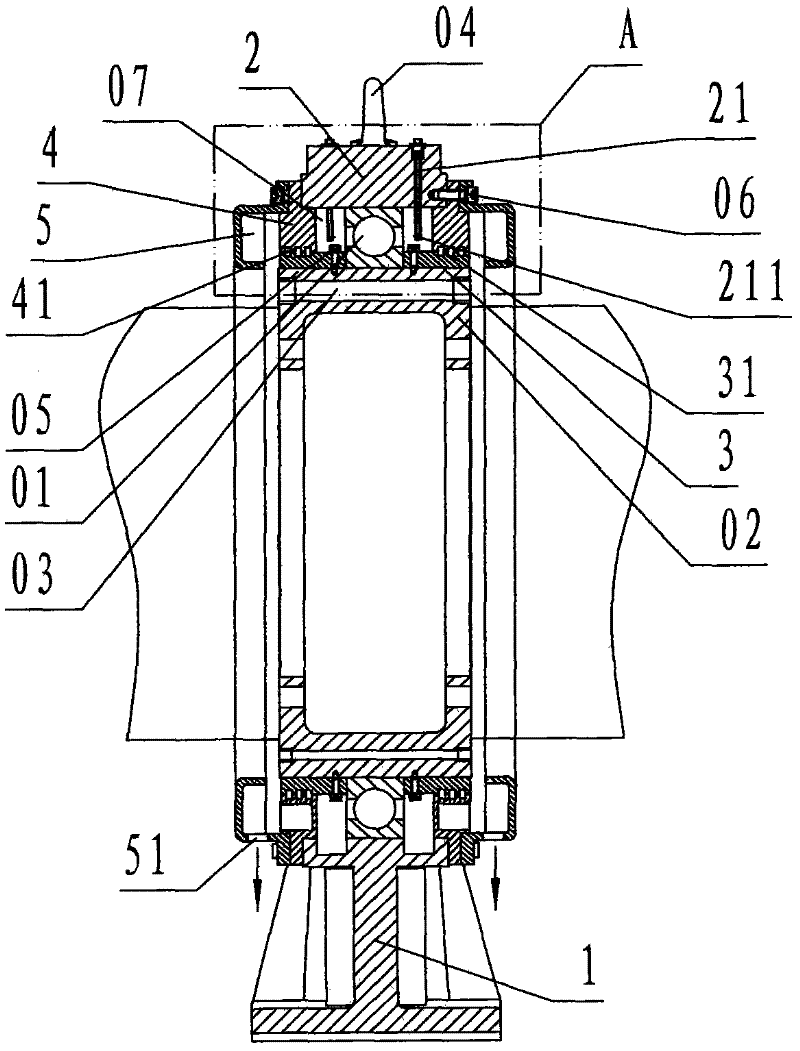

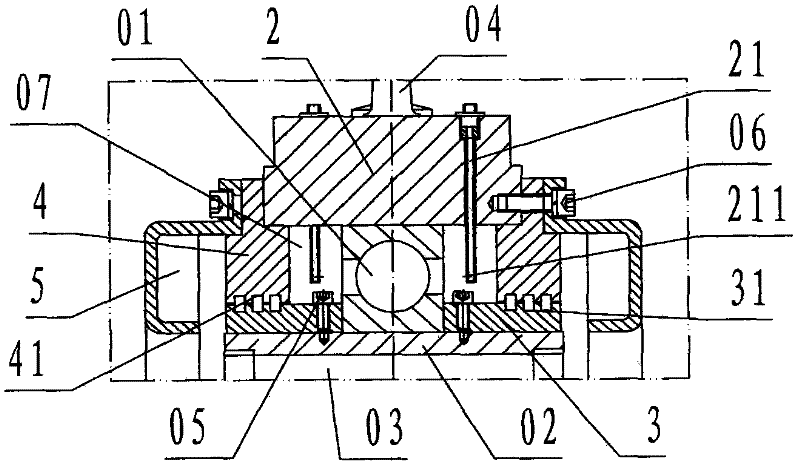

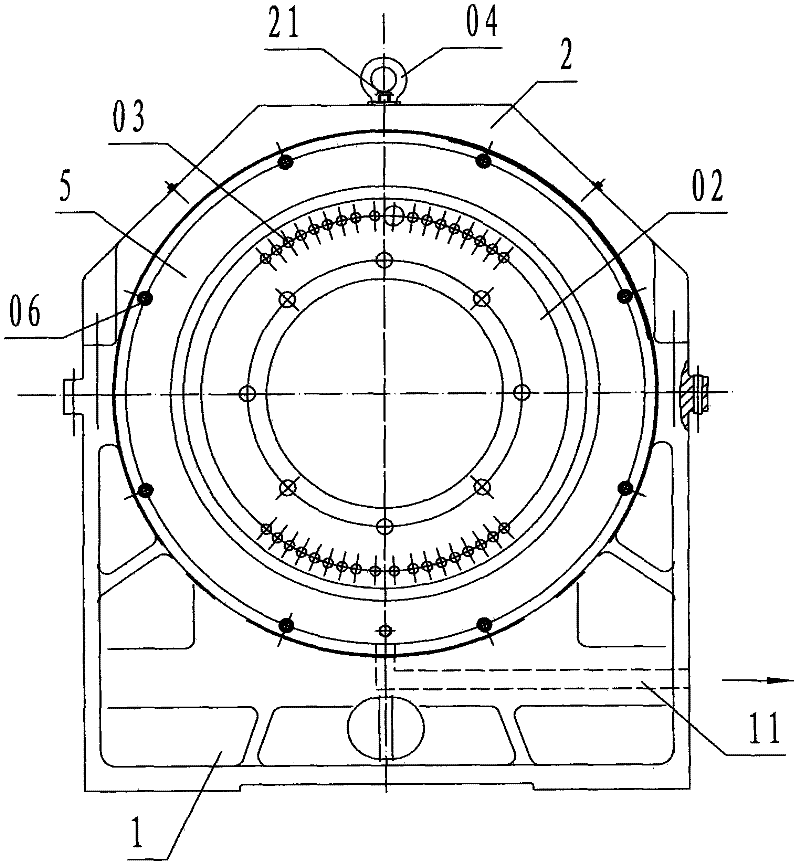

[0026] refer to Figure 1 ~ Figure 3 , a bearing seat device of the present invention in a pulsed liquid grease circulation lubrication mode for a wire rope stranding machine, comprising a base 1, an upper cover 2, a thrust ring 3, an end cover 4, and an anti-leakage cover 5, wherein: the base 1 is the lower half of the bearing seat, which is used to carry the steel bracket base of the rolling bearing 01; the upper center of the base 1 is provided with a semicircular groove that is statically matched with the outer diameter of the rolling bearing 01, called the upper groove , one side of the lower part of the base 1 is provided with a main oil return channel 11 formed by a through hole communicating with the upper groove;

[0027]The upper cover 2 is the upper half of the bearing seat, which is used to cooperate with the base 1 to hug and fix the steel gland of the rolling bearing 01; the lower center of the upper cover 2 is provided with a static fit The semicircular groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com