Motorized spindle of aerostatic bearing

A technology of aerostatic bearing and electric spindle, which is applied in the direction of large fixed members, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of affecting processing accuracy, poor ball roundness, large vibration, etc., to improve work efficiency , Improve the cooling effect, improve the effect of operating accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

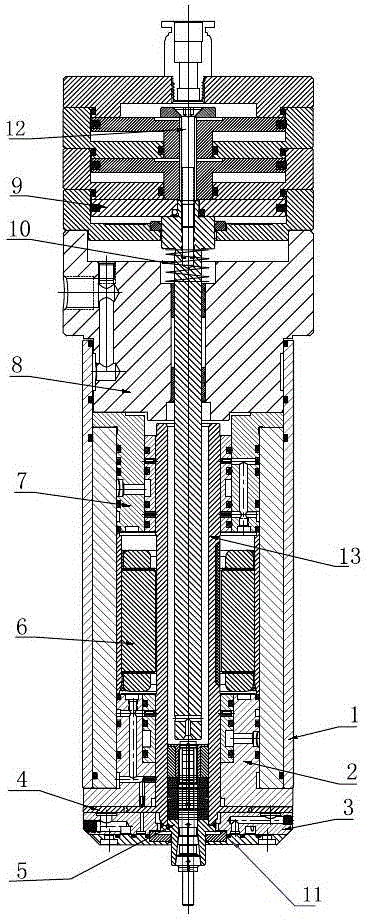

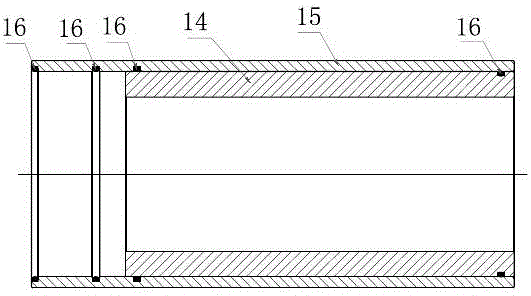

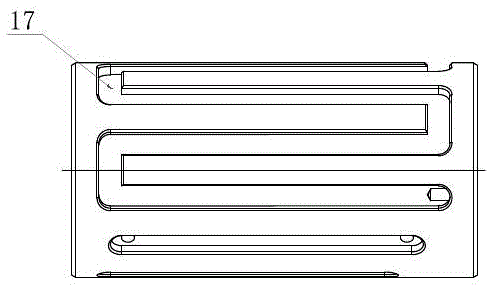

[0029] Aerostatic bearing electric spindle, including coaxially arranged main body assembly 1, shaft core 13, front bearing assembly 2, rear bearing assembly 7, thrust bearing 3, stator assembly 6, rotor assembly 5, water / air passage sleeve assembly 8 and Cylinder assembly 9; wherein: the rear end of the rotor assembly 5 is connected to the cylinder assembly 9, and on the periphery of the rotor assembly 5 there are water / air line sleeve assembly 8, rear bearing assembly 7, stator assembly 6 and front bearing assembly 2 in sequence from back to front , on the periphery of the rotor assembly 5, in the rear bearing assembly 7, the stator assembly 6 and the front bearing assembly 2, a shaft core 13 is provided, the front portion of the shaft core 13 has an outwardly protruding edge, and the edge is a flying disc, The flying disc is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com