Juicer

A juicer and stand technology, which is applied in the field of food processing equipment, can solve problems such as high product cost and hidden troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

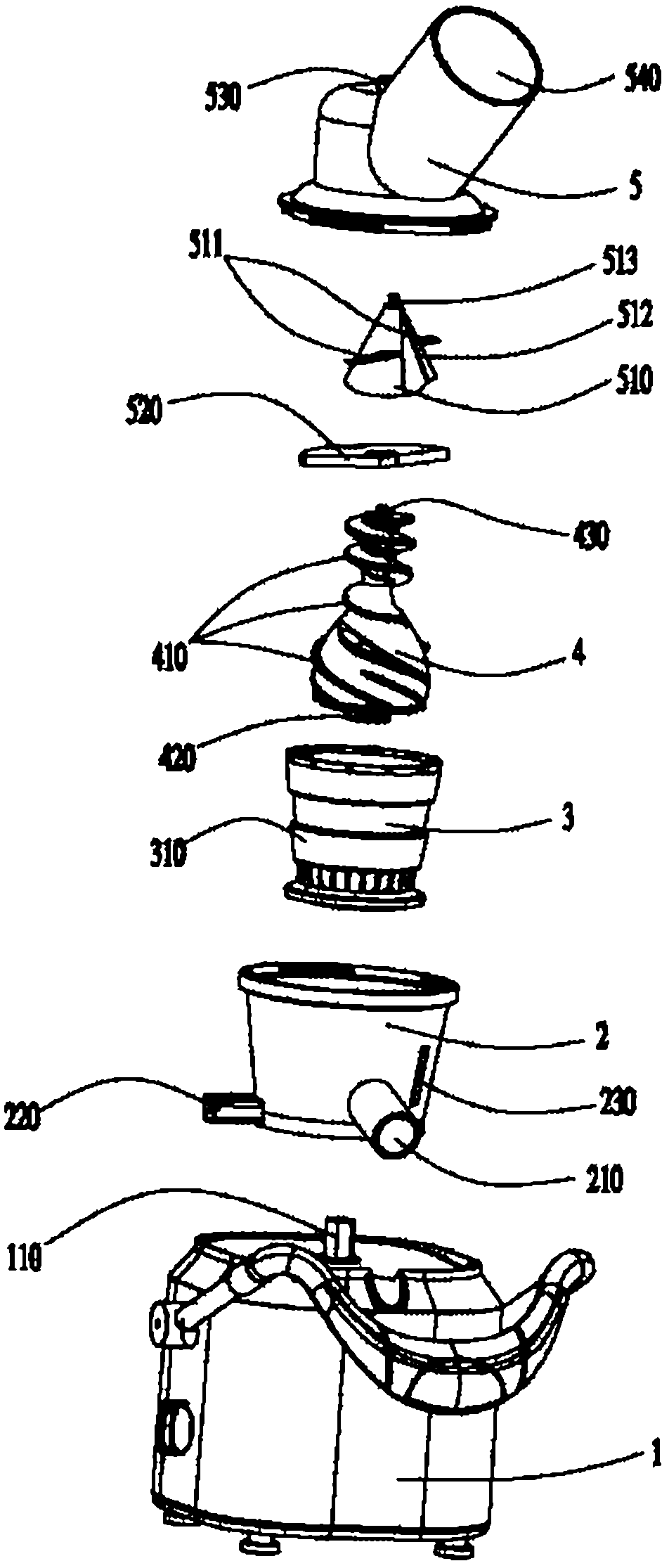

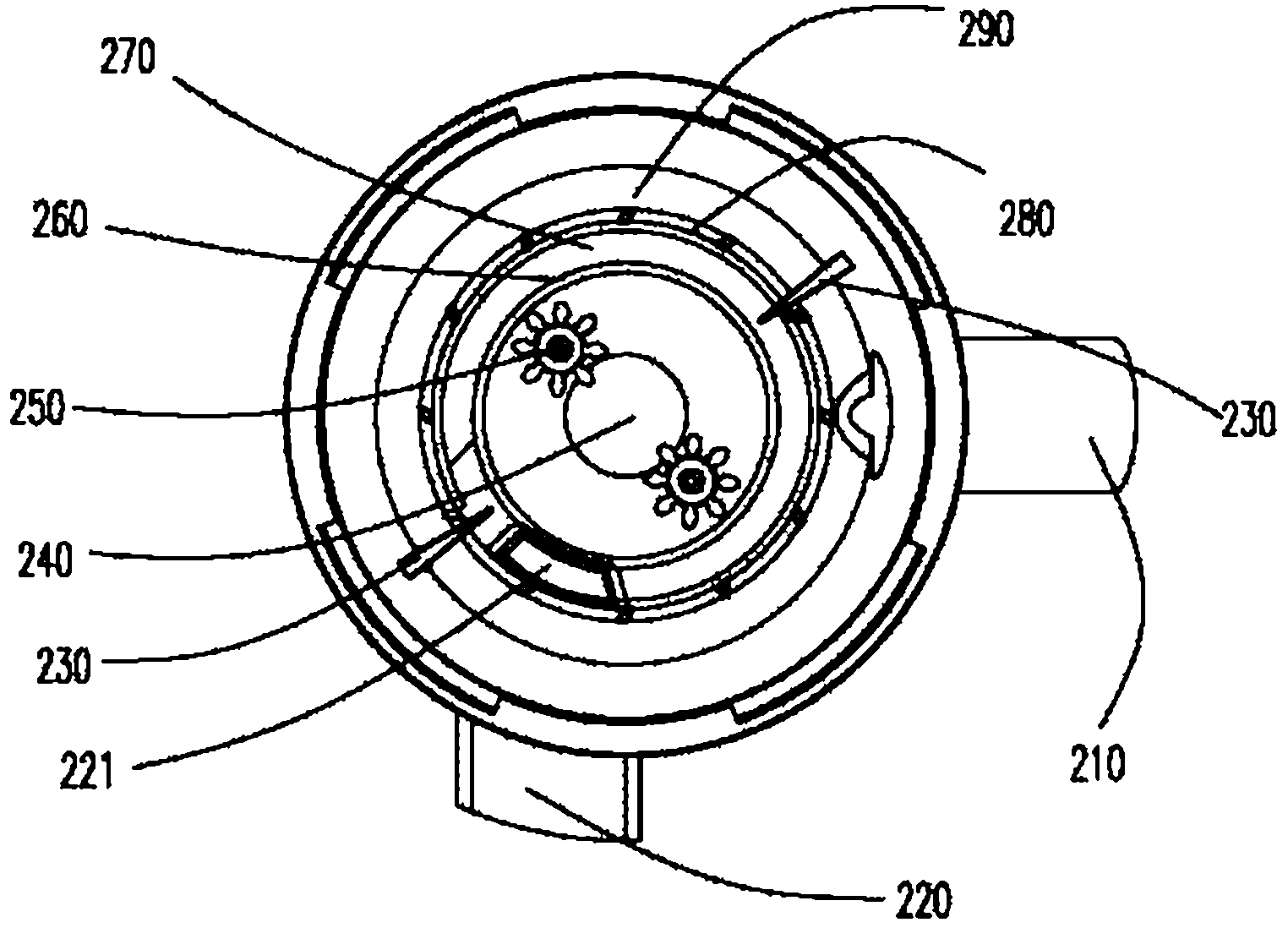

[0064] Embodiment one, with reference to Figure 1 to Figure 13 as well as Figure 18 and Figure 20 As shown, the embodiment of the present invention provides a juice extractor, including a machine base 1 with a transmission mechanism, a squeezing device located above the machine base 1, and an upper cover 5 placed above the squeezing device, the The squeezing device is composed of: a separator 2 that can discharge the juice and residue of the juiced food separately; a filter screen 3 that can filter the residue of the juiced food; a rotating head 4 that can screw squeeze the juiced food; The side wall of the separator 2 is provided with a juice outlet 210, the bottom of the separator 2 is provided with a slag outlet 220, and the bottom of the filter screen 3 is provided with a slag discharge hole 350 movably connected with the slag outlet 220. The rotating head 4 is provided with a spiral piece 410, the rotating head 4 is placed in the separator 2, the filter screen 3 is s...

Embodiment 2

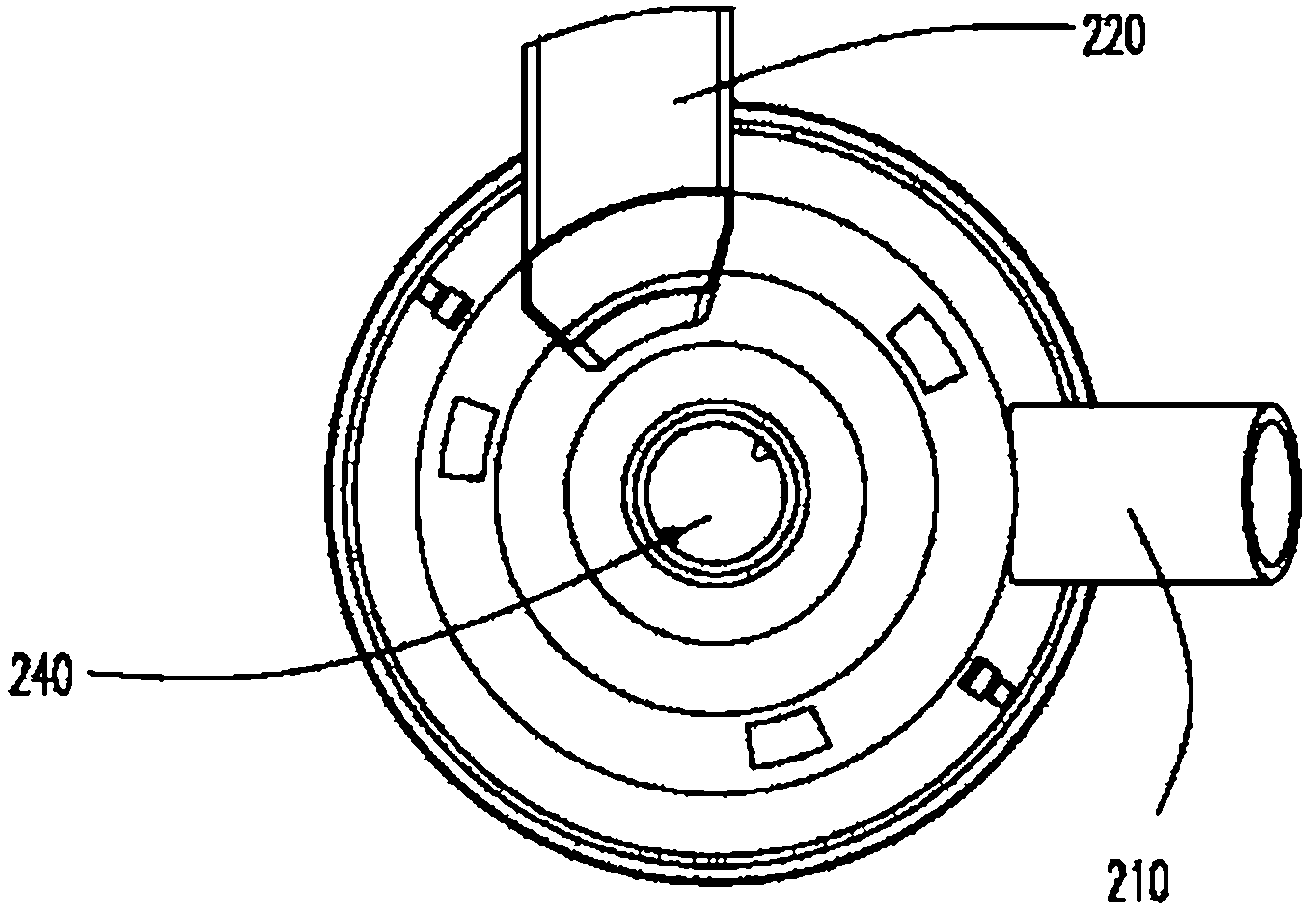

[0080] Embodiment two, refer to Figure 14 to Figure 17 As shown, the embodiment of the present invention provides a juice extractor, the main difference from the second embodiment above is that the base 1a is also provided with a second driving end 120a connected to the lower end of the filter 3a, which can drive the filter The net 3a rotates in the same direction or in the opposite direction to the rotating head 4a to achieve a greater extrusion force, and it can also move in the same direction to avoid damage to the juicer when the food is stuck. At the same time, When there is a problem with the first driving end 110a or the second driving end 120a, the other driving end can continue to complete the work. Further, the bottom of the filter screen 3a is provided with the lower end of the first driving end 110a or the rotating head 4a. The third through hole 320a passing through the center, the outer surface of the bottom of the filter screen 3a, a driver 331a is arranged aro...

Embodiment 3

[0081] Embodiment three, refer to Figure 19 and Figure 20 As shown, the embodiment of the present invention provides a juice extractor, the main difference from the above-mentioned embodiments is that a cutting controller 520 is arranged above the rotating head 4, and the cutting controller 520 is fan-shaped and fixed on the On the upper edge of the separator 2, when the user installs the tangent controller 520 on the upper edge of the separator 2, then the upper cover 5 and the separator 2 are closed and assembled, which avoids the difficulty of closing the upper cover 5 in the previous embodiment. The tangent controller 520 is unstable and easy to fall off, and it is also more convenient for users to install, disassemble and clean.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com