SMT wiring terminal convenient to operate

It is a terminal block and easy-to-operate technology. It is applied in the direction of electrical connection seat, clamping/spring connection, etc. It can solve the problems of crooked insertion, inconvenient operation, damage, etc. of the wire head, and achieves strong practicability, convenient clamping and loosening, and The effect of prolonging the service life and reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

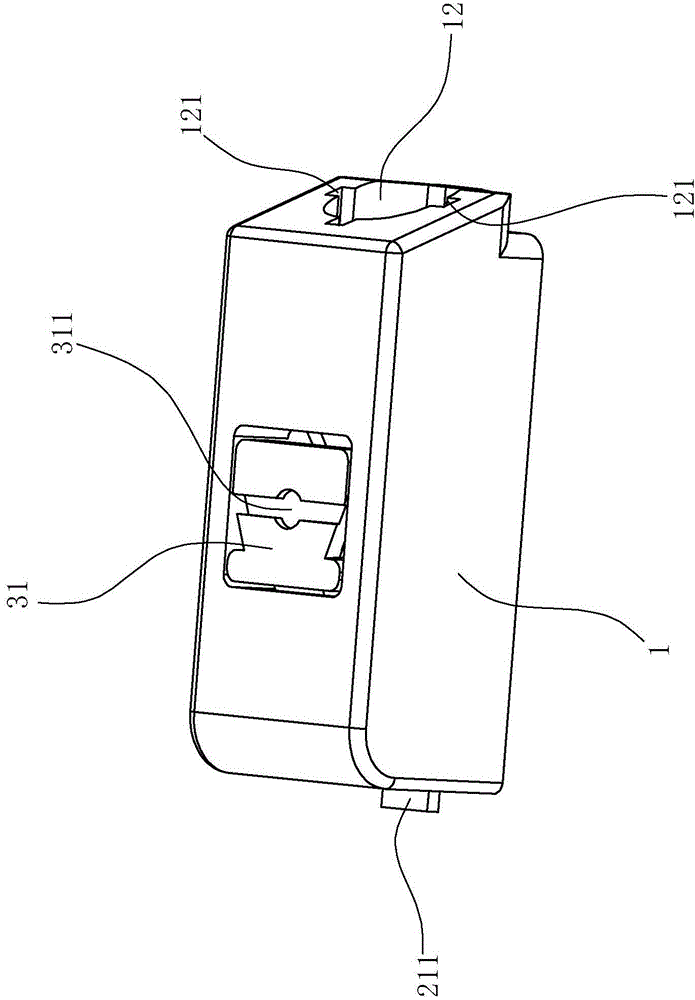

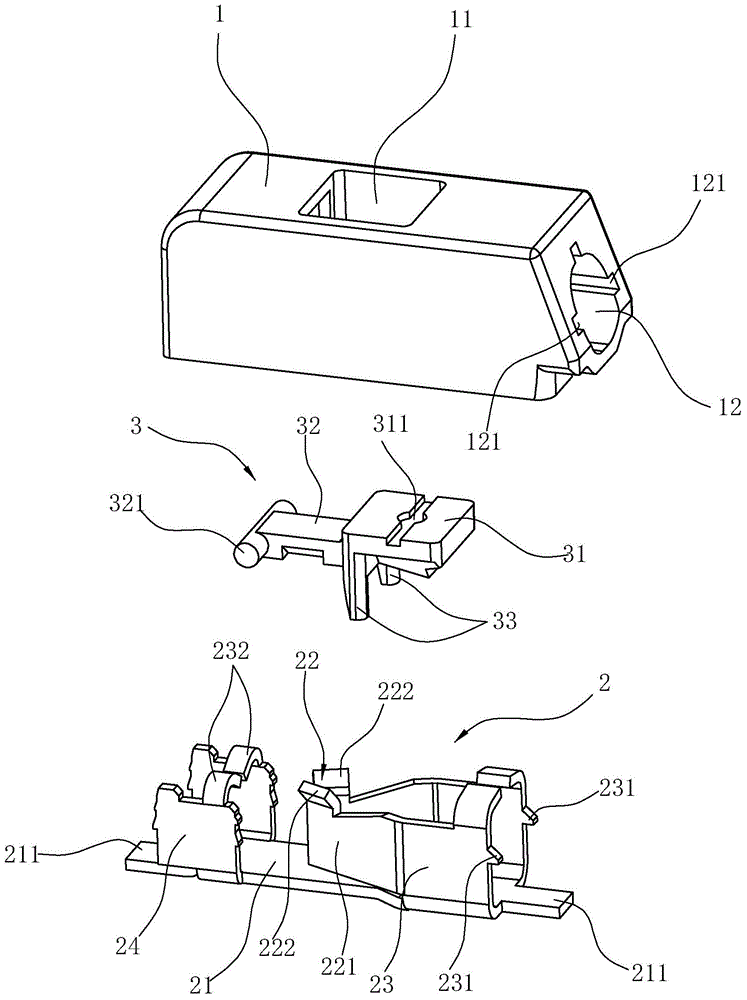

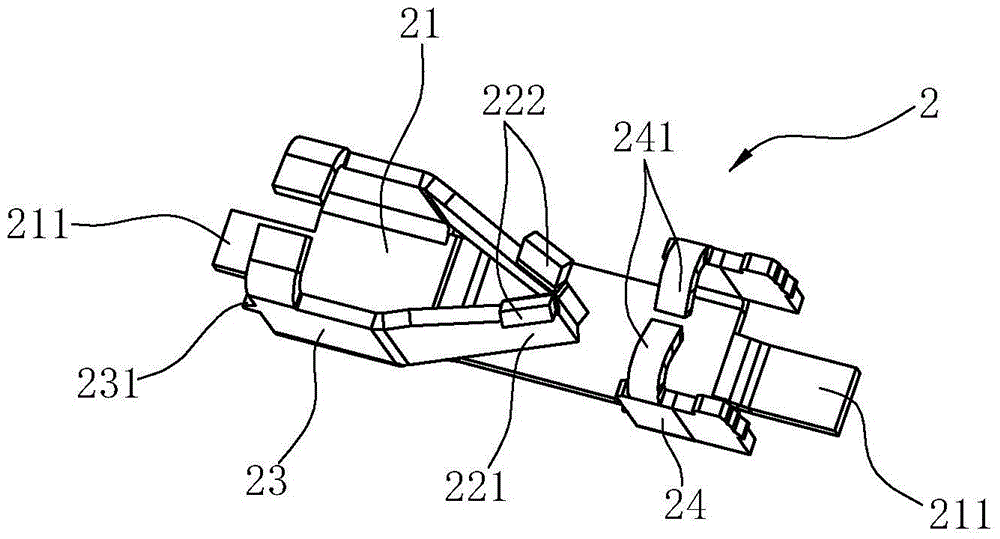

[0025] Such as Figure 1 to Figure 7 As shown, the present embodiment relates to a SMT connection terminal, which includes an insulating housing 1, a conductor 2 and a button 3, wherein the top of the housing 1 is provided with a square through hole 11, and a part of the housing 1 There is a socket 12 on the side for the insertion of wires, and the conductor 2 is arranged in the housing 1. The conductor 2 includes a body 21, a clamping part 22 for clamping the wires, and a rebound structure for the reset of the button 3. , the button 3 is disposed in the through hole 11 of the casing 1, and the button 3 can make the clamping portion 22 of the conductor 2 open and return elastically.

[0026] In this embodiment, the body 21 of the conductor 2 is a strip-shaped conductive sheet arranged across the bottom of the housing 1. Solder legs 211 extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com