Five-axis linkage simulation machining method of dental prosthesis

A dental restoration and five-axis linkage technology, applied in metal processing equipment, manufacturing tools, milling machine equipment, etc., can solve problems such as low occlusal function, long production cycle, and poor processing shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0062] Embodiment: Process the oral prosthesis according to the following specific steps:

[0063] (1) Reconstruct the digital model of the affected tooth

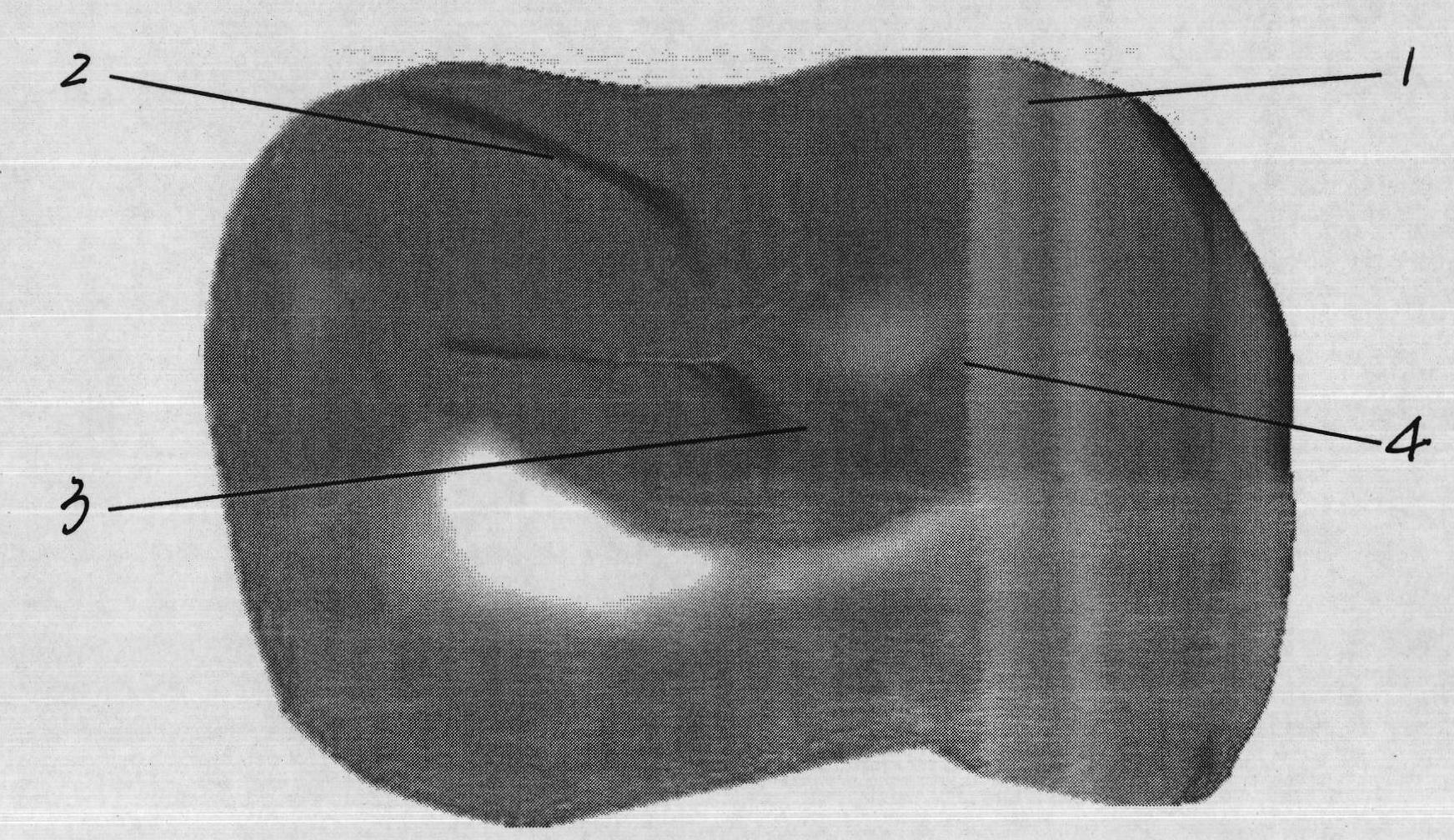

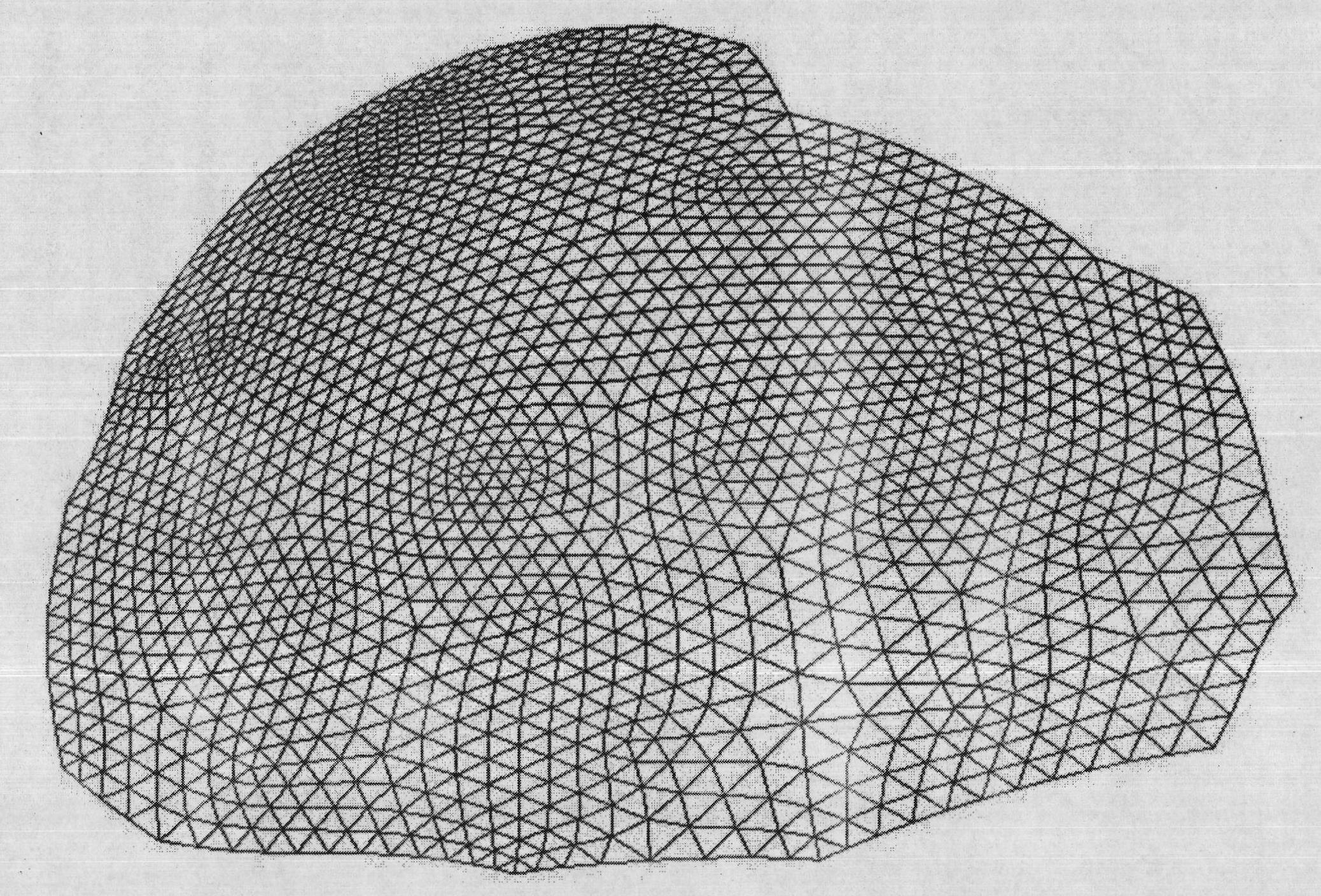

[0064] In the dental restoration CAD / CAM system, the original features of the symmetrical teeth on the patient’s dentition and their occlusal teeth are collected, and the digital model of the affected tooth is reconstructed. The digital model is a triangular mesh model, that is, an STL model, such as image 3 As shown, a series of triangular slices are used to approximate the actual tooth occlusal surface;

[0065] (2) Discrimination of feature surface type

[0066] When the length of the groove is shortened to a certain extent, it degenerates into a pit, and when the length of the crest shortens to a certain extent, it degenerates into a point. It is impossible to strictly distinguish the groove from the pit, the crest from the tip, the groove from the pit, The method of distinguishing crests and peaks is as follows: Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com