Method for mounting shipping stern shaft tube lining

A technology for stern tubes and bushings, which is applied to ship components, ship construction, transportation and packaging, etc., which can solve problems such as greater impact on installation quality, discarded bushings, and long installation process cycles, saving time and avoiding The effect of scrapping and saving the cost of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

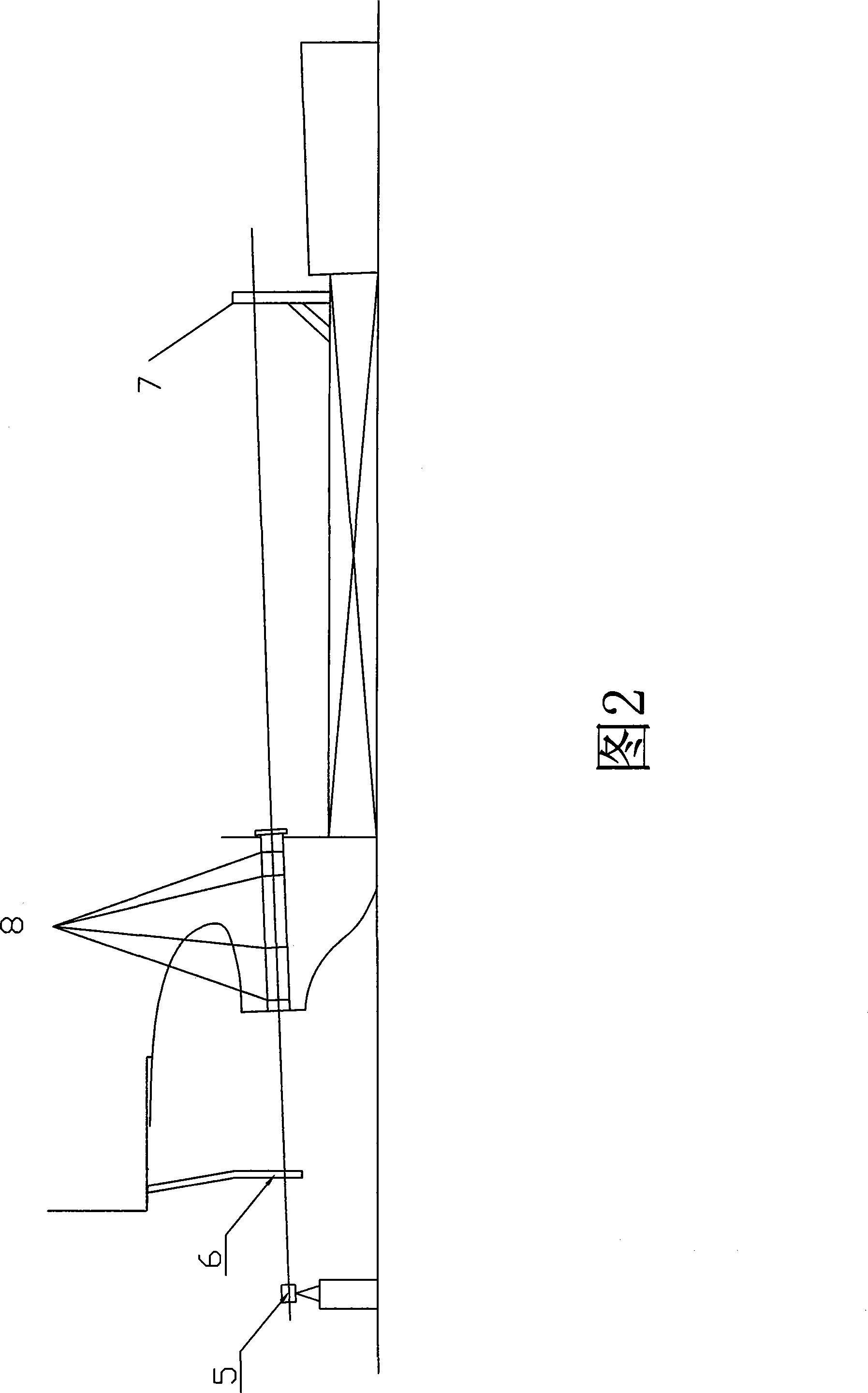

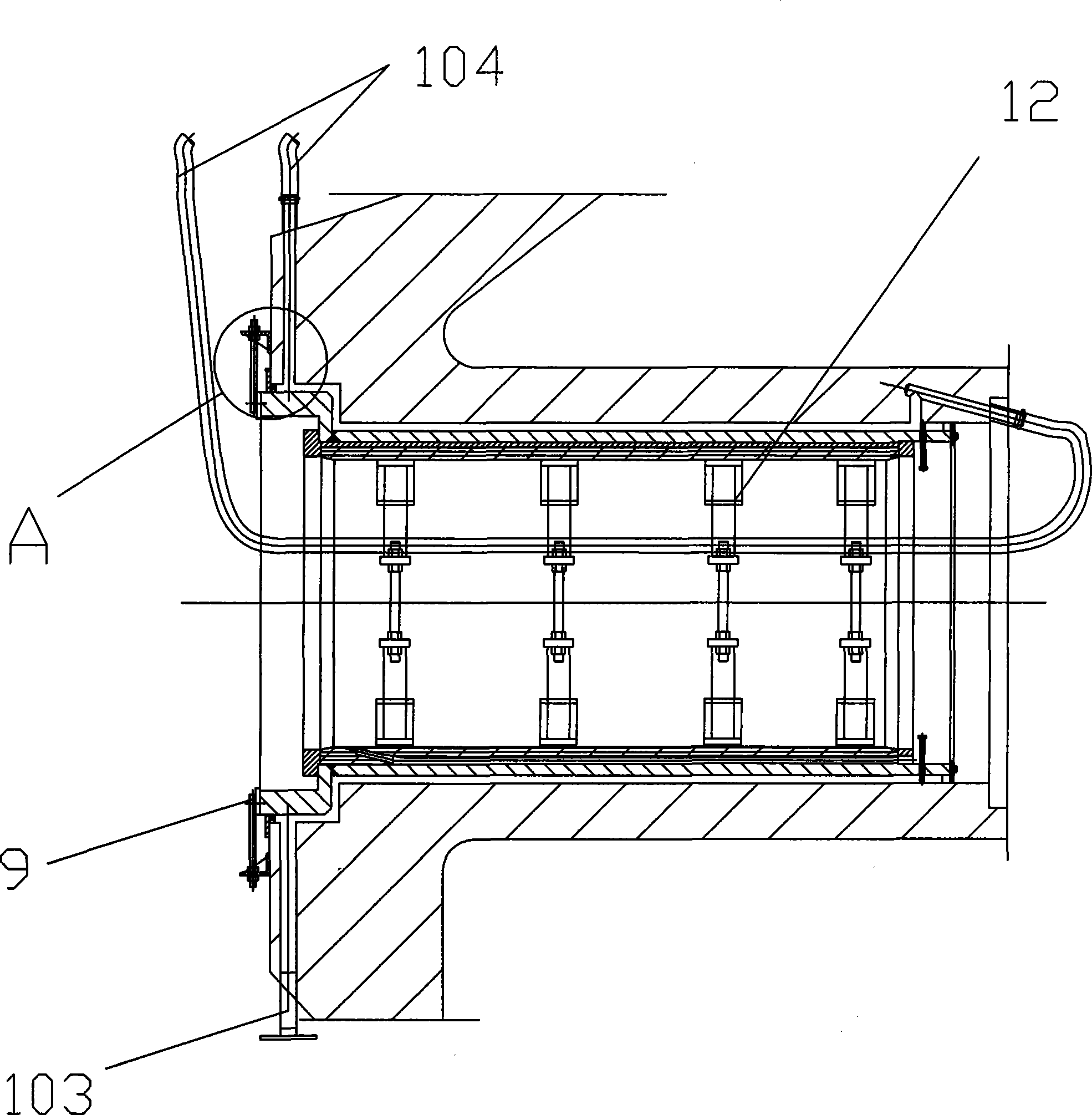

[0033] Below, we will further describe the method for installing the ship stern tube bush by pouring epoxy resin according to the present invention in combination with the accompanying drawings and specific embodiments, but the scope of protection of the present invention cannot be limited accordingly.

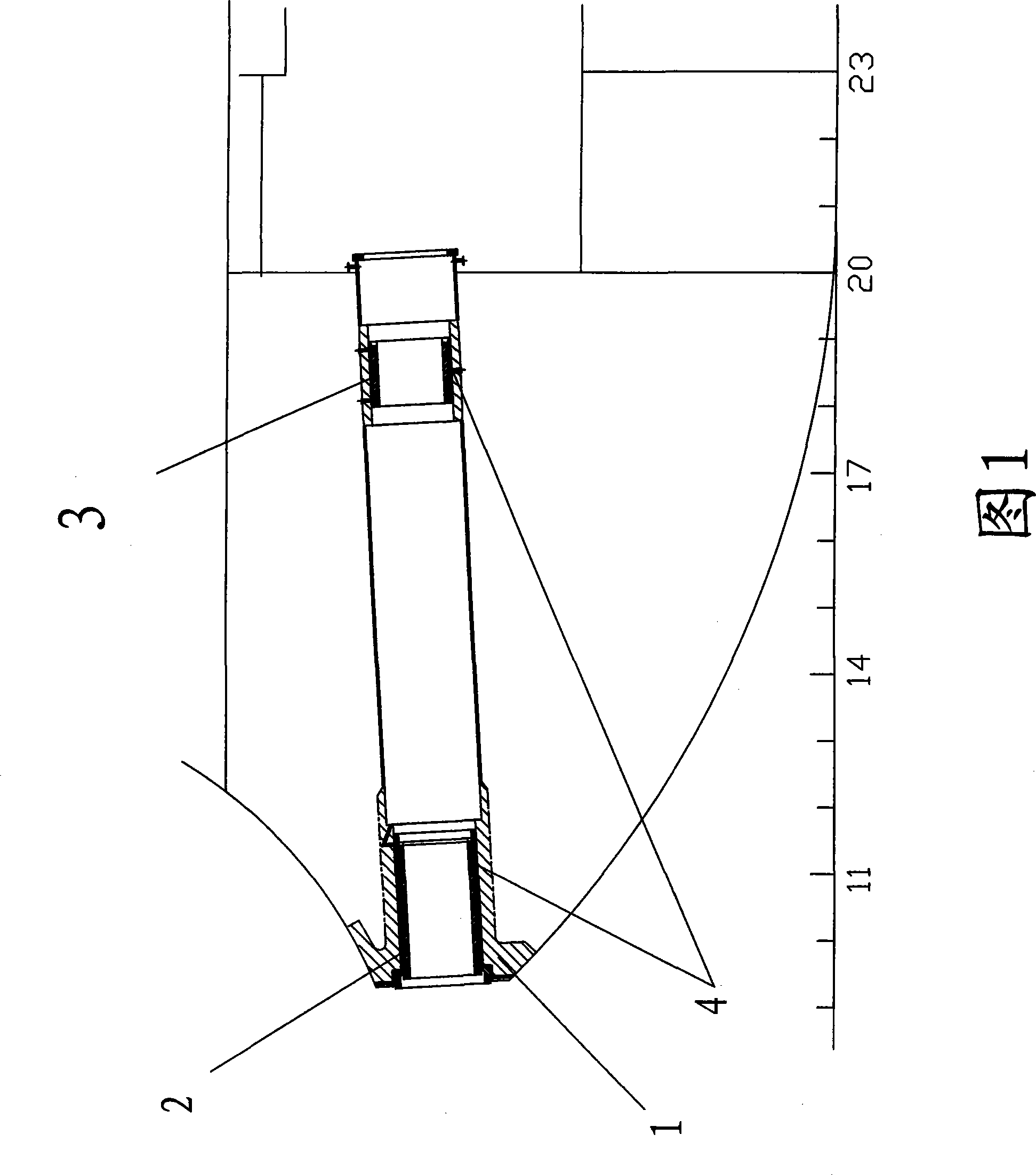

[0034] Please see Fig. 1, Fig. 1 is a schematic view after installation in an embodiment of a method for installing a ship stern tube bushing according to the present invention. The method of installing the ship stern tube bushing by pouring epoxy resin according to the present invention is epoxy resin between the installed bush and the stern tube, the center position is very accurate, the installation precision is high, the strength is high, and the cost is greatly saved. Human and material resources.

[0035] The method for installing the ship stern tube bushing by pouring epoxy resin in the present invention specifically comprises the following steps:

[0036] ① Process th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com