Power distribution cabinet with heat dissipation and fire extinguishing functions

A power distribution cabinet and functional technology, applied in the substation/distribution device casing, electrical components, substation/switch layout details, etc., can solve the problems of reduced heat dissipation effect, insufficient heat dissipation efficiency, damage, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

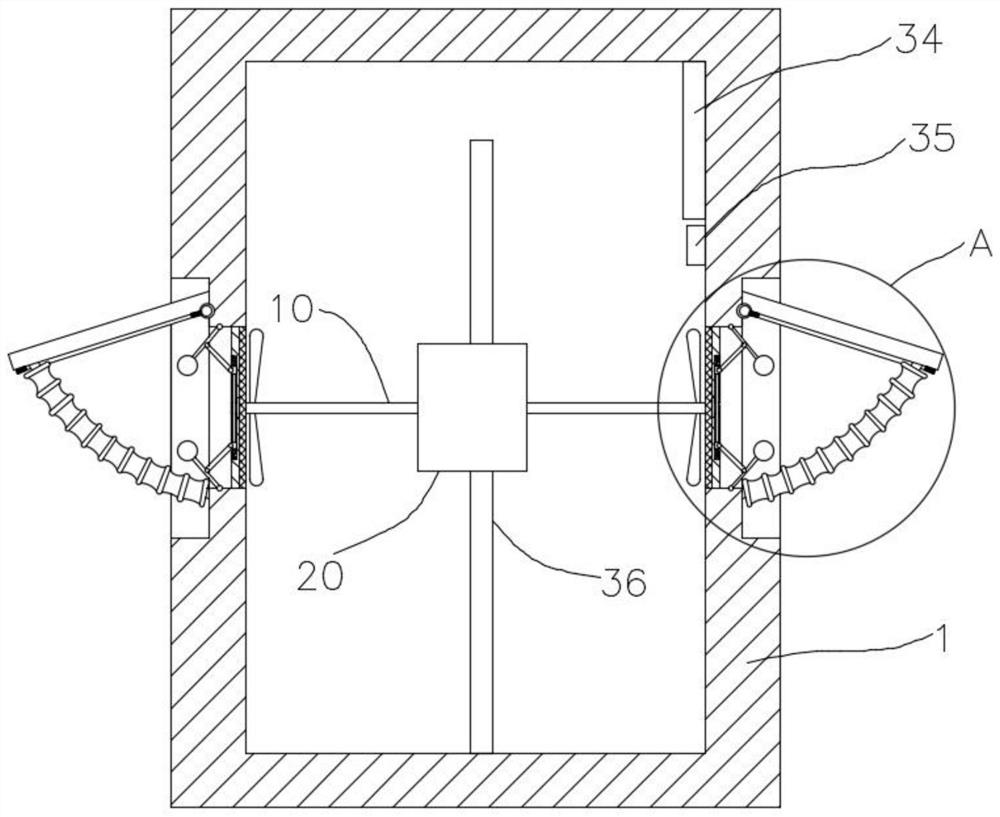

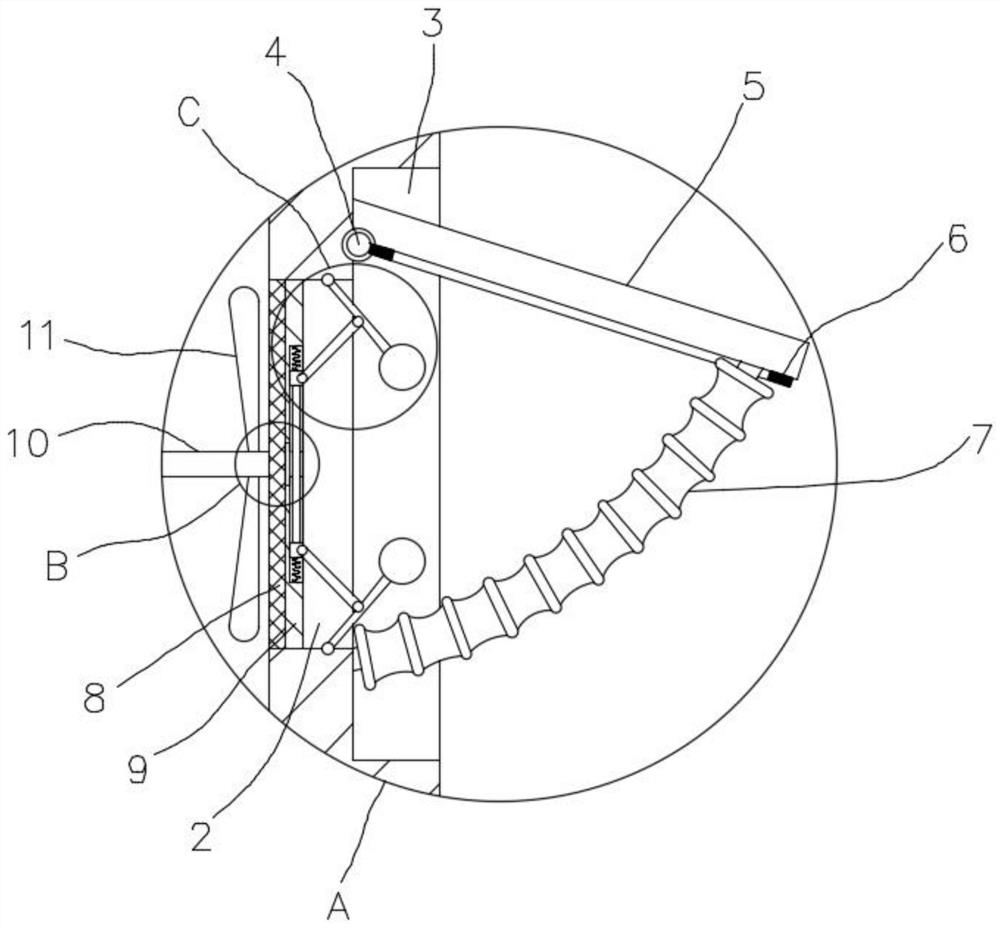

[0025] refer to Figure 1-5 , a power distribution cabinet with heat dissipation and fire extinguishing functions, including a cabinet body 1, and two sides of the cabinet body 1 are symmetrically provided with stepped vents, and the vents are composed of an inner vent 2 and an outer vent 3 that communicate from the inside to the outside The inner wall of the upper end of the outer vent 3 away from the inner vent 2 is rotated by the rotating shaft 4 to install a rain shield 5, and the rain shield 5 and the inner wall of the lower end of the outer vent 3 are jointly sealed and connected with an arc-shaped bellows 7, The bellows 7 forms an arc after inflation, and the side of the rain shield 5 near the inner vent 2 is glued and fixedly connected with a frame-shaped gasket 6 whose shape is larger than the inner vent 2, and the arc bellows 7 is connected with a release Air pipe, and a solenoid valve is installed on the air discharge pipe;

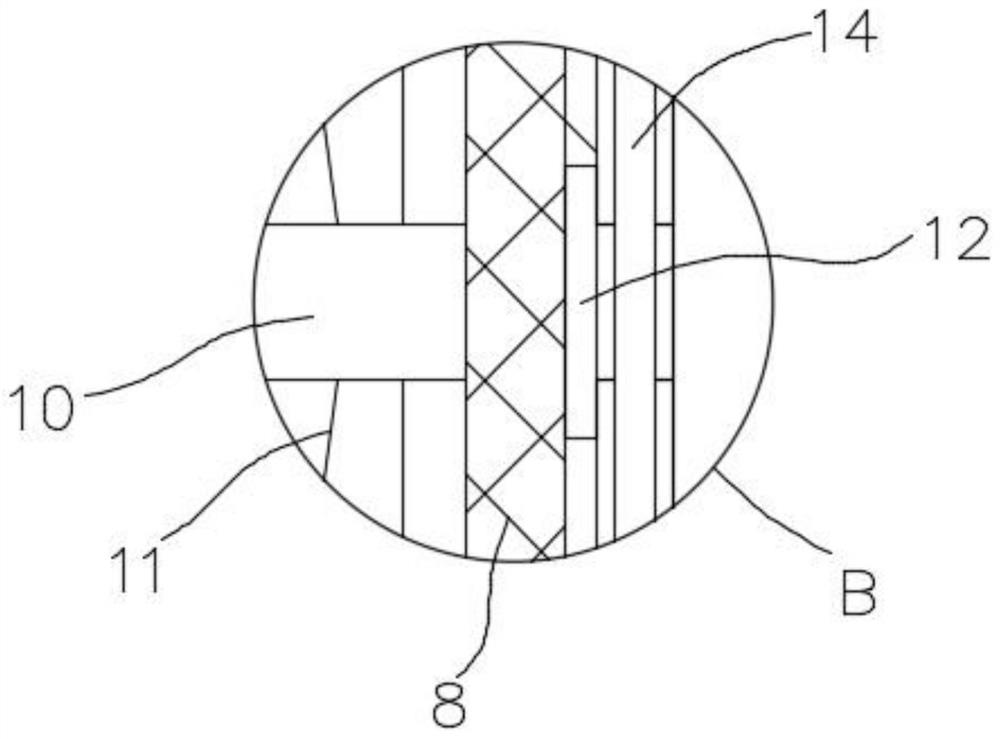

[0026] The inner wall of the inner air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com