Intelligent water saving toilet and intelligent flushing control method

A smart toilet technology, applied in the field of sanitary ware, can solve problems such as large randomness of human operation, inability to automatically control flushing time and flushing volume, toilet leakage, etc., and achieve the effects of reducing mechanical failures, saving space, and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

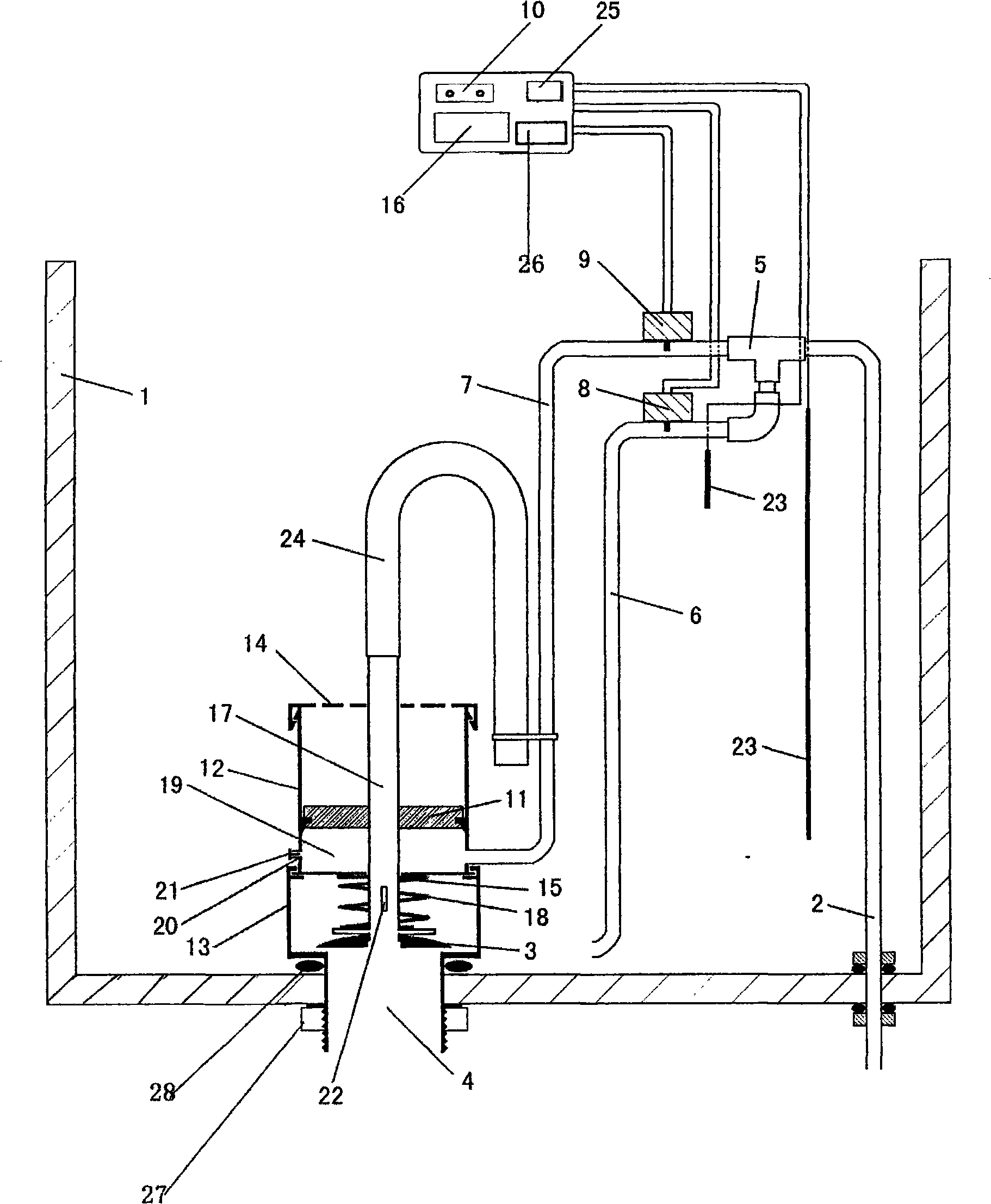

[0034] The intelligent water-saving toilet includes a water tank 1 and a water inlet pipe 2, a drain valve 3, and a water outlet 4 in the water tank 1. The water inlet pipe 2 is connected to the water injection pipe 6 and the pressure pipe 7 through a tee 5; the connection between the pressure pipe 7 and the drain valve 3 A hydraulic cylinder for opening and closing the drain valve 3 is arranged between them. The purpose of the tee 5 is to allow the water in the water inlet pipe 2 to enter the water injection pipe 6 and the drain pipe, and other structures / mechanisms to achieve this purpose are equally applicable. The water injection pipe 6 and the pressure pipe 7 are respectively provided with a water injection electric valve 8 and a drainage electric valve 9, and are electrically connected with the infrared controller.

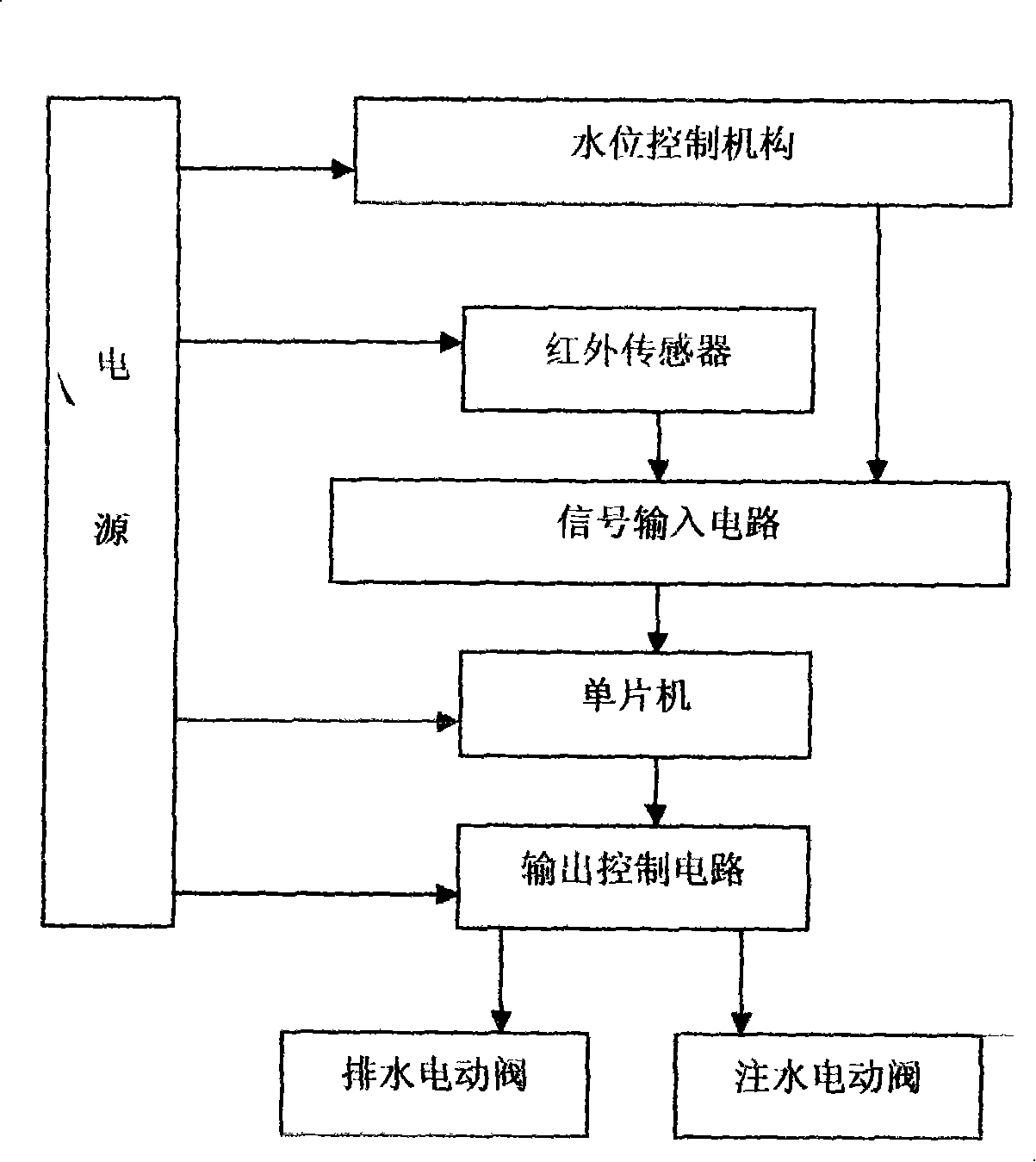

[0035] Infrared controller comprises infrared sensor 10, single-chip microcomputer 16, power supply 26, output control circuit 25, and infrared sensor is co...

Embodiment 2

[0038] The hydraulic cylinder of the intelligent water-saving toilet of the present invention includes a cylinder body 12 with a piston 11 disposed therein and a valve seat 13 located at the drain outlet 4 at the lower part of the cylinder body 12, and the valve seat 13 is installed at the drain outlet 4 of the water tank 1 . The upper end of the cylinder body 12 is provided with a cylinder cover 14 and the lower end is provided with a cylinder bottom 15 . The piston 11 is connected with a connecting rod 17, and the connecting rod 17 passes downward through the cylinder bottom 15 to connect with the drain valve 3 at the drain port 4, and a spring 18 is arranged between the drain valve 3 and the cylinder bottom 15; a sealing ring is embedded on the periphery of the piston A sealed hydraulic cavity 19 is formed between the cylinder bottom 15 and the periphery of the valve seat 13 is airtight. The upper end of the valve seat 13 is connected with the cylinder body 12. The valve se...

Embodiment 3

[0040] In order to make the drain valve 3 and the piston 11 return to their original positions after flushing, a pressure relief hole 20 is set on the outer wall of the hydraulic chamber 19 of the cylinder body 12, and the water in the hydraulic chamber 19 flows to the cylinder through the pressure relief hole 20. Outside the body 12, under the action of the elongation force of the spring 18, the drain valve 3 recloses the drain port 4, and the pressure relief hole 20 is provided with a flow control knob 21 to control the pressure relief speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com