An energy integration optimization method for industrial circulating cooling water

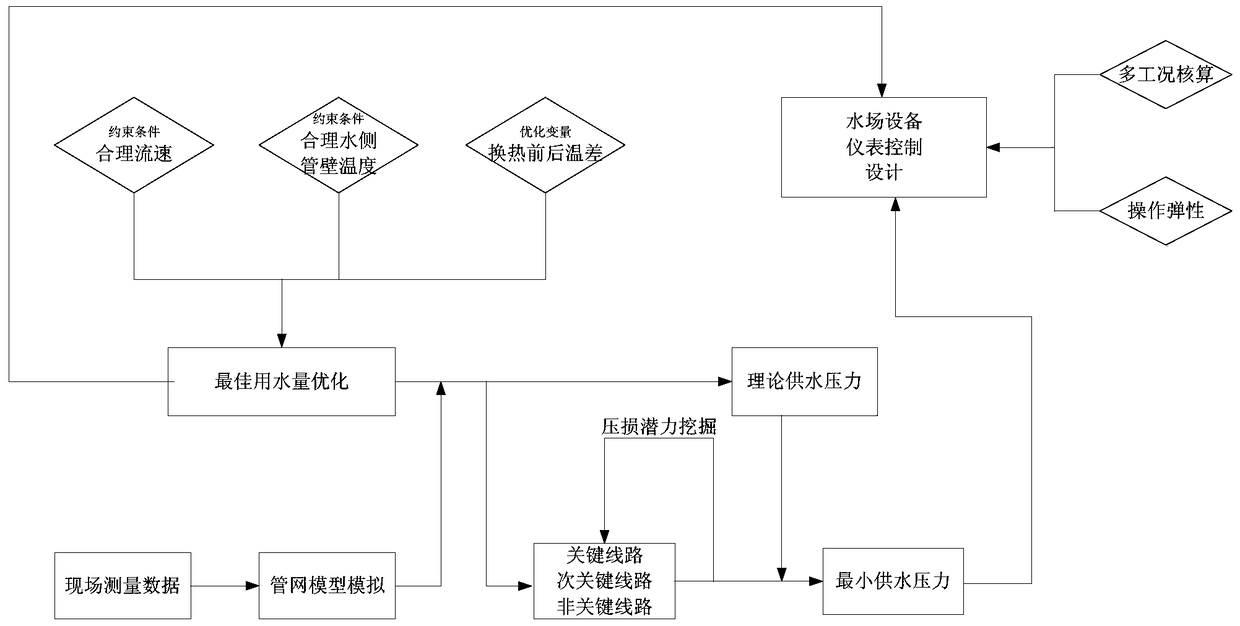

A technology of circulating cooling water and optimizing methods, which is applied in the energy industry, sustainable manufacturing/processing, instruments, etc., can solve the problems of large water consumption in the cooling system, high system header pressure, poor cooling effect of the cooling water tower, etc., to improve the operation. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

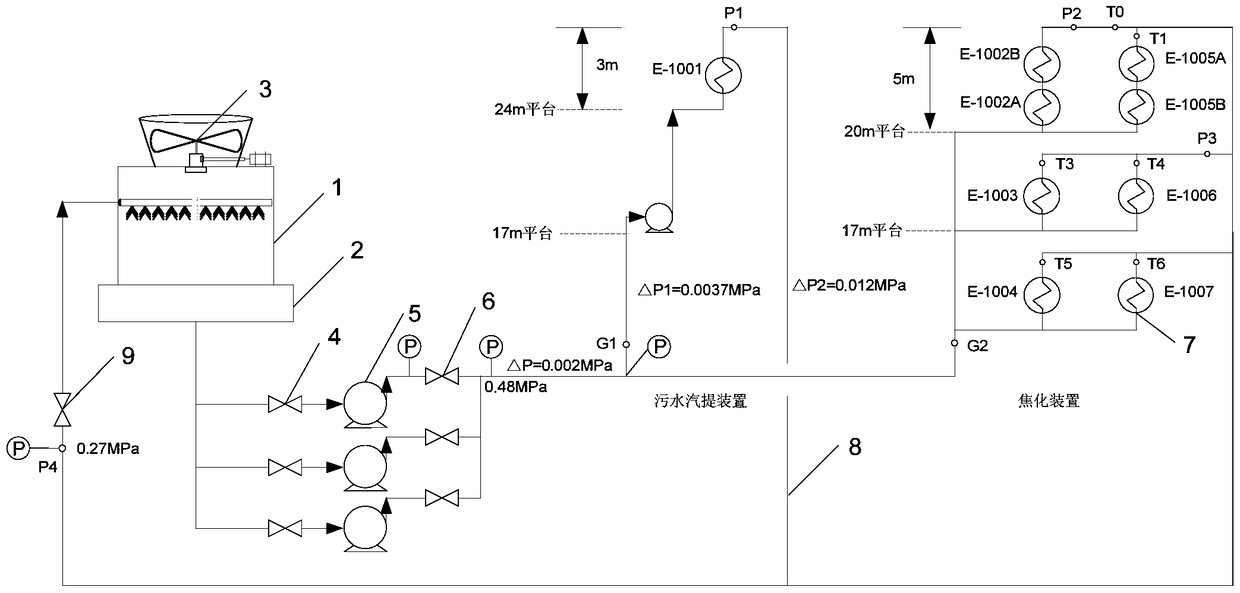

[0068] The industrial circulating cooling water system involved in the present invention includes a cooling tower 1, a clear water pool 2, a cooling fan 3, a circulating water pump inlet valve 4, a circulating water pump 5, a circulating water pump outlet valve 6, a circulating water system pipeline 8, and a cooling tower where the return water pipe enters Front valve 9 and water coolers E-1001, E-1002A / E-1002B, E-1003, etc. in the device.

[0069] The embodiment is a circulating water system of an oil refinery. The circulating water field provides circulating water for the sewage stripping unit and coking unit, and the designed circulating water volume is 5000m 3 / h, the circulating water field consists of 1 cooling tower 1, including 2 counterflow mechanical ventilation towers, 2 cooling fans 3, 3 vertical circulating water pumps of the same model 5, and the rated flow rate of a single pump is 1702m 3 / h, rated head 52m, rated power 355kW, two circulating water pumps 5 are w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com