Horizontal well stage-unlimited sectional reconstruction method

A segmented transformation and infinite-level technology, which is applied to earthwork drilling, wellbore/well components, wellbore/well valve devices, etc., can solve complex operations, long construction periods, and inability to realize infinite-level segmental transformation, etc. problems, to achieve simple operation, improve reliability, and reduce mechanical failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for infinitely staged segmental reconstruction of a horizontal well, comprising the following steps:

[0038] a. The signal receiver on the sliding sleeve sends the search signal within the set range;

[0039] b. Put the signal transmitter into the well. When the signal transmitter enters the set range, the signal transmitter receives the search signal and sends a control signal to the signal receiver;

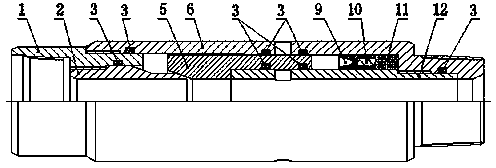

[0040] c. After the signal receiver receives the control signal, it activates the power mechanism, pushes the piston to move upward, opens the sandblasting hole, opens the internal and external communication channels of the oil pipe, and under the action of the piston, the ball seat forming cylinder of the sliding sleeve forms a ball seat, Implement the first stage of transformation;

[0041] d. After the first section of transformation is completed, throw the ball to make it sit on the ball seat formed by the ball seat generating cylinder, block the first sec...

Embodiment 2

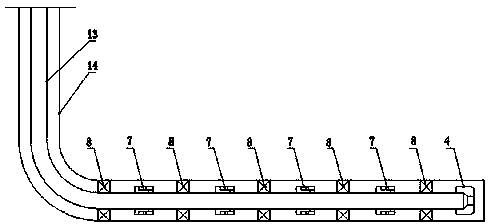

[0052] like figure 2 As shown, after the packer 8 and the guide shoe 4 are set, the sliding sleeve with the outer diameter similar to the oil pipe 13 or casing 14 is connected to the oil pipe or casing, and lowered to a predetermined position. By putting a low-frequency signal transmitter into the well, the signal receiver 11 sends a coded signal to search for the signal transmitter within the effective range to approach, and when the signal transmitter receives the signal, it will decode and verify the coded signal , when the signal transmitter is successfully identified, it will send a high-frequency coded message to the signal receiver 11 on the sleeve, and the signal receiver 11 will receive the high-frequency message and decode it. If the identified information matches, Then the igniter 10 will be excited, and the shaped energy bomb 9 will be ignited. The high-energy gas produced by the shaped energy bomb 9 will push the piston 5, expose the sandblasting hole, open the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com