Cylinder body cleaning machine and cleaning method thereof

A cleaning machine and cylinder body technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve problems such as cleaning, cylinder surface damage, and cylinder surface residues, so as to avoid failures , transmission performance and transmission accuracy guarantee, and the effect of guaranteeing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

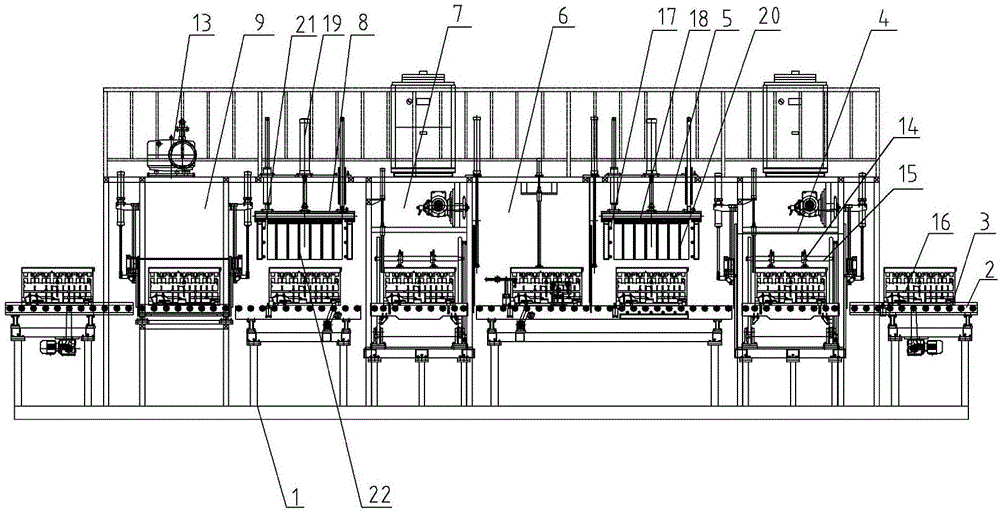

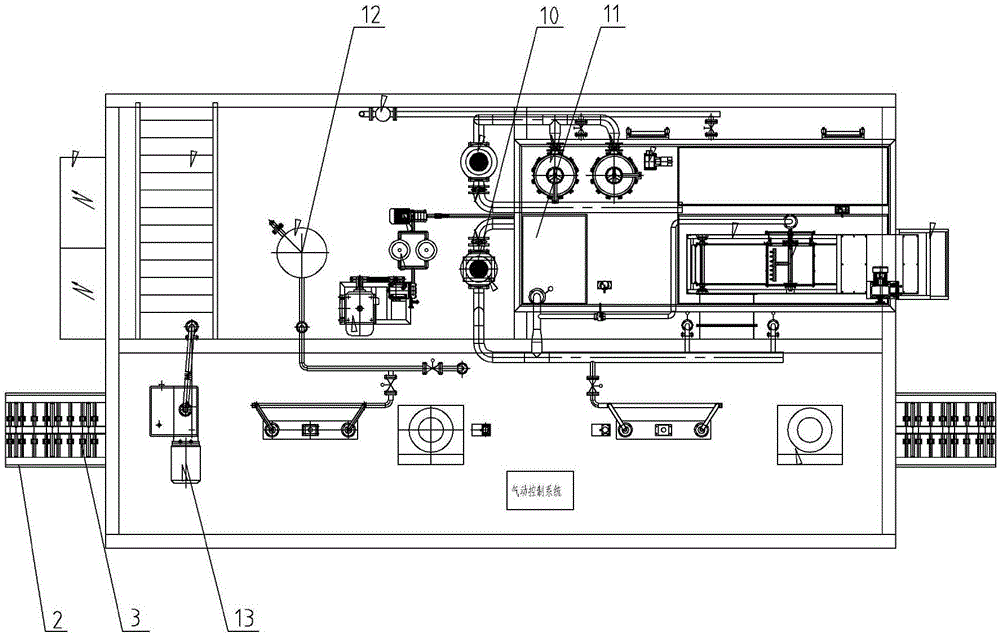

[0024] Refer to attached figure 1 , 2 , the present invention comprises frame 1, and the middle position of frame 1 is equipped with guide rail 2, and guide rail 2 is provided with cylinder conveying mechanism 3, and frame 1 is successively provided with the eddy current cleaning chamber 4 that is positioned at the top of cylinder conveying mechanism 3, Alignment cleaning chamber 5, high-pressure cleaning chamber 6, rotary pouring chamber 7, alignment blowing water chamber 8 and vacuum drying chamber 9, vortex cleaning chamber 4, convection cleaning chamber, high-pressure cleaning chamber 6 through the pipeline provided with cleaning pump 10 It is communicated with the cleaning liquid storage tank 11, and the rotary pouring chamber 7 and the counter blowing chamber 8 are respectively communicated with the air storage tank 12;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com