Patents

Literature

34results about How to "Achieve circumferential limit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

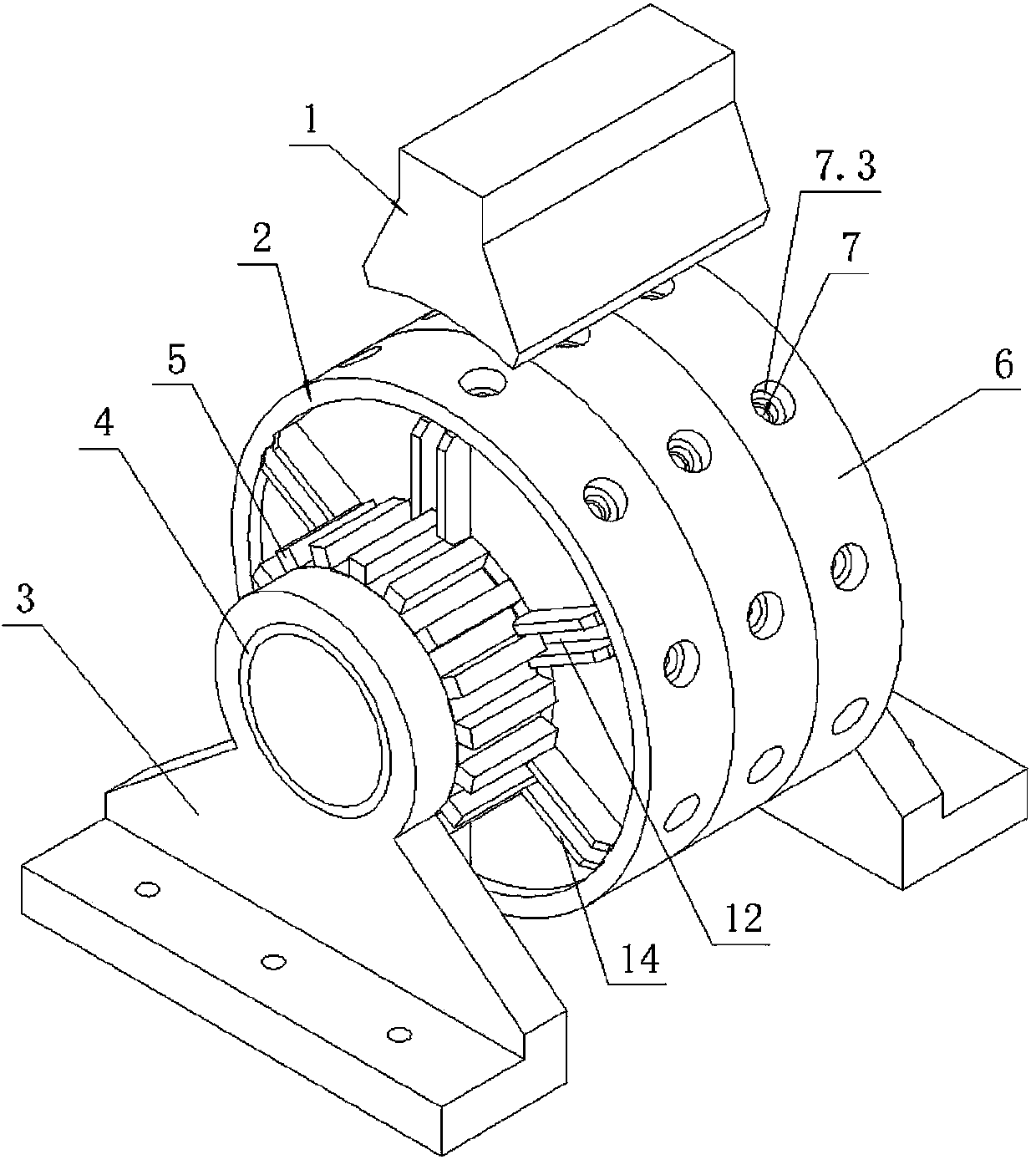

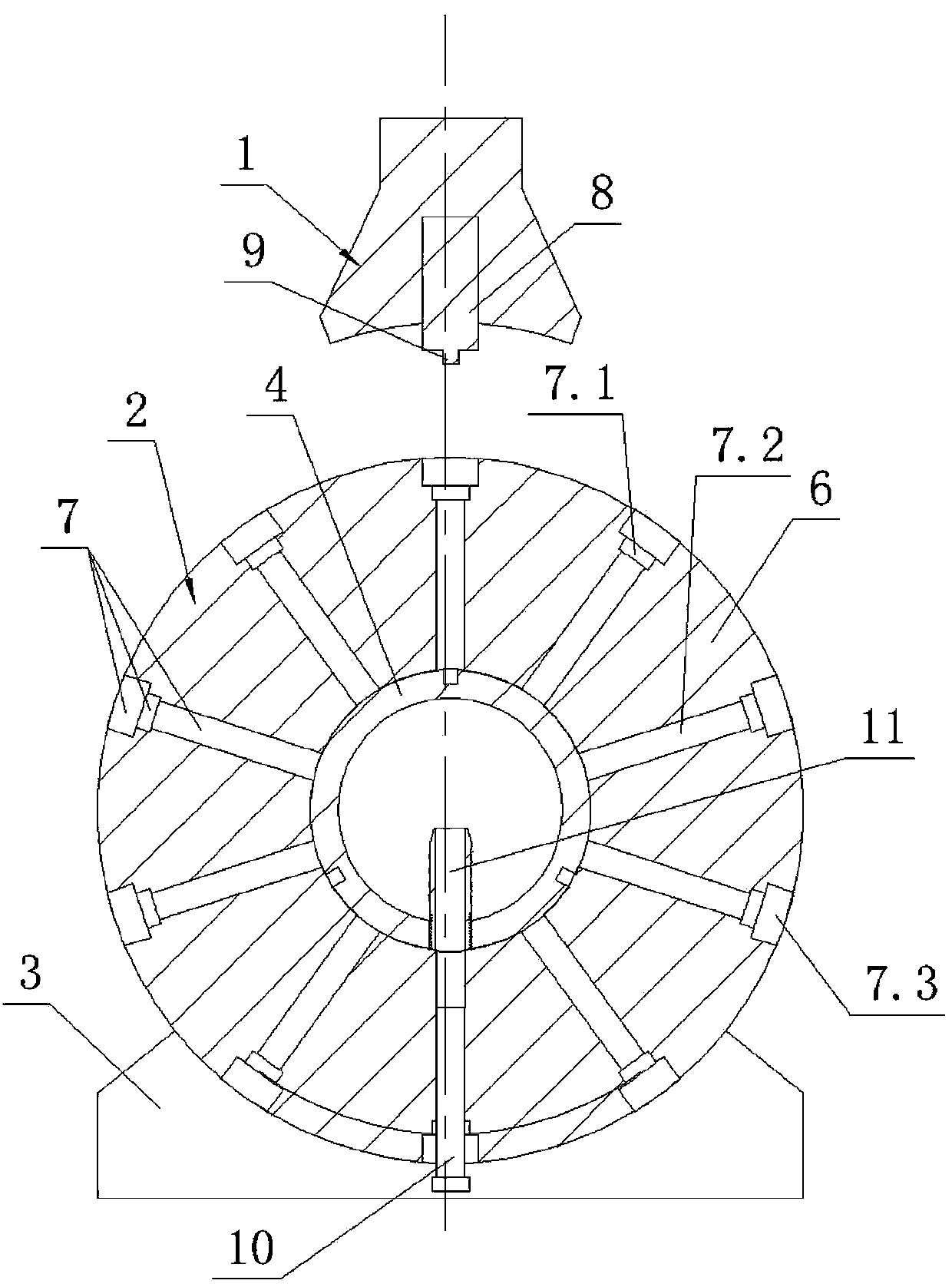

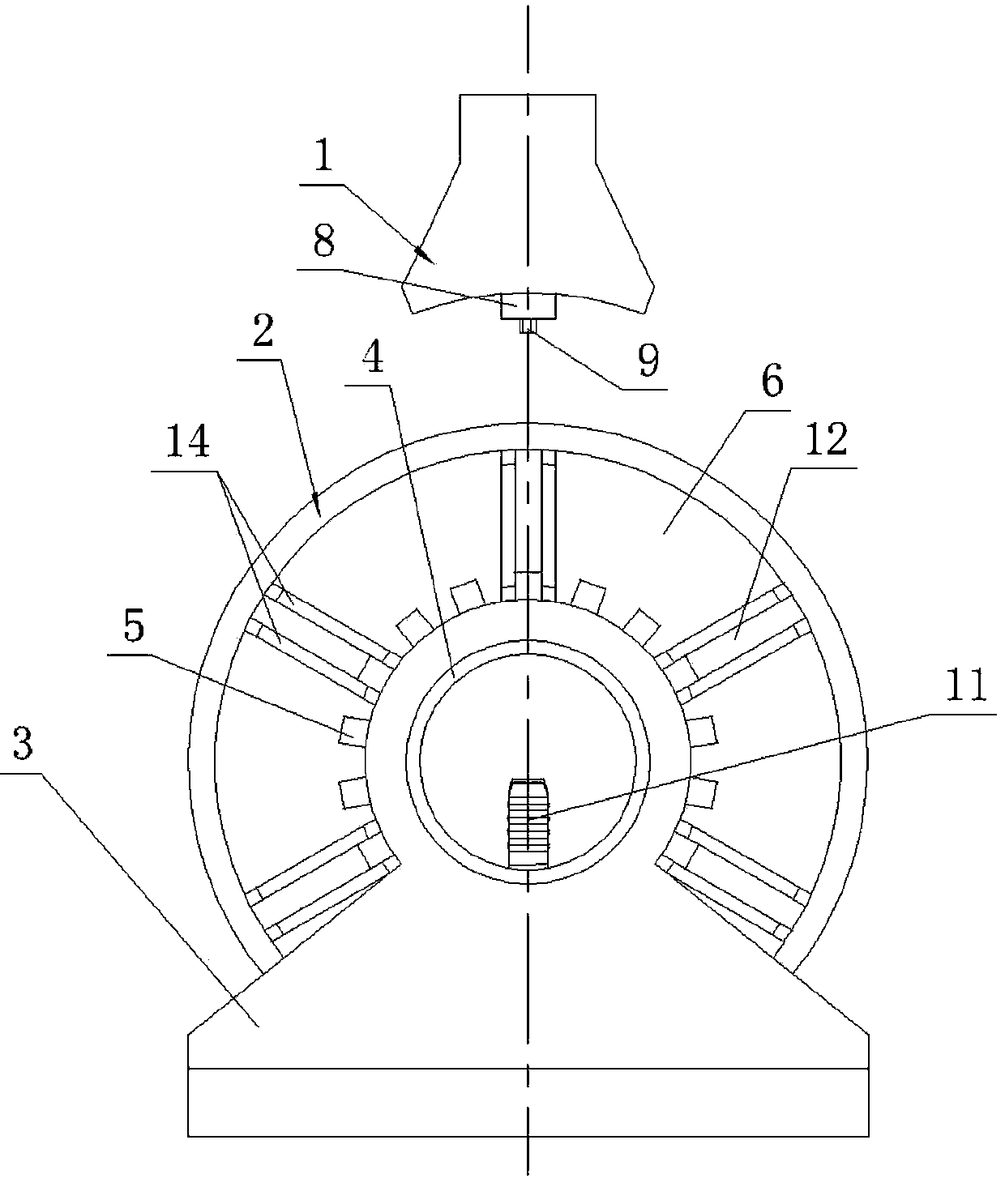

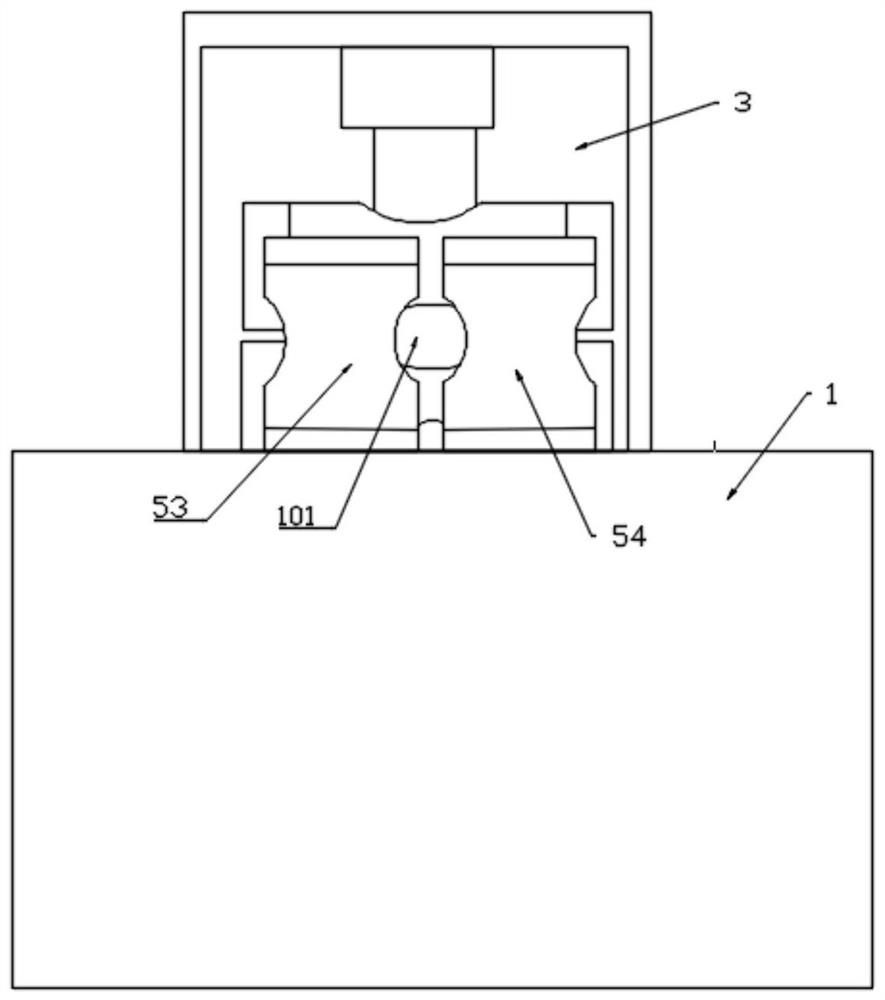

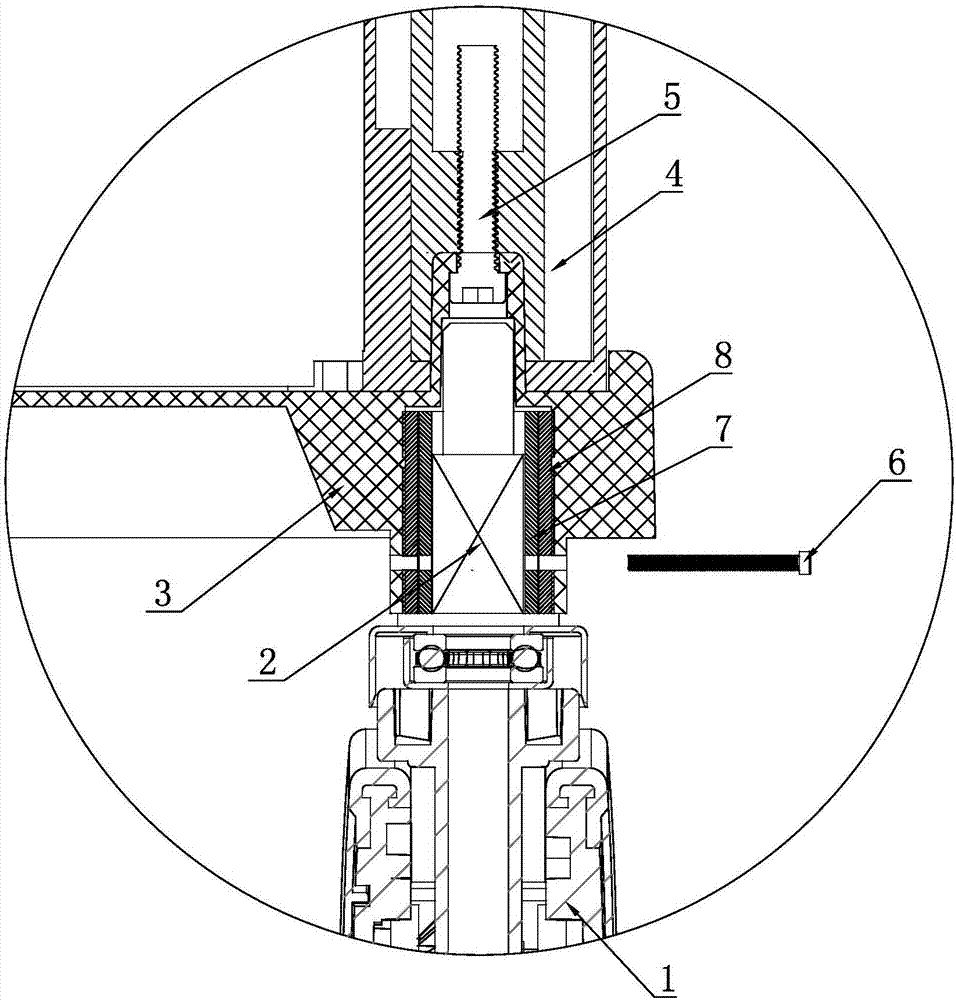

Stamping tool

InactiveCN103464644AShort tripPut an end to the safety hazard of smashing and injuring people's handsShaping toolsNutsEngineeringNozzle

The invention discloses a stamping tool comprising a punch (1) and a die shell (2). The die shell (2) comprises two supports (3), a rotary shaft (4), a transmission gear and at least two rotary plates (6). Two ends of the rotary shaft (4) are fixed to the two supports (3) respectively. The transmission gear and all rotary plates (6) are rotatably fitted to the rotary shaft (4) in a sleeving manner. The outer peripheral surface of the each rotary plate (6) is provided with a plurality of radial through holes (7). The punch (1) is provided with at least two stamping posts (8) as many as the rotary plates (6). The stamping posts (8) are arranged in a row and right face a highest row of radial through holes (7) in the rotary plates (6). The rotary shaft (4) is further connected with a nozzle (11). The stamping tool is high in stamping speed, efficient, safe, and handy.

Owner:泰州市凌峰机电设备有限公司

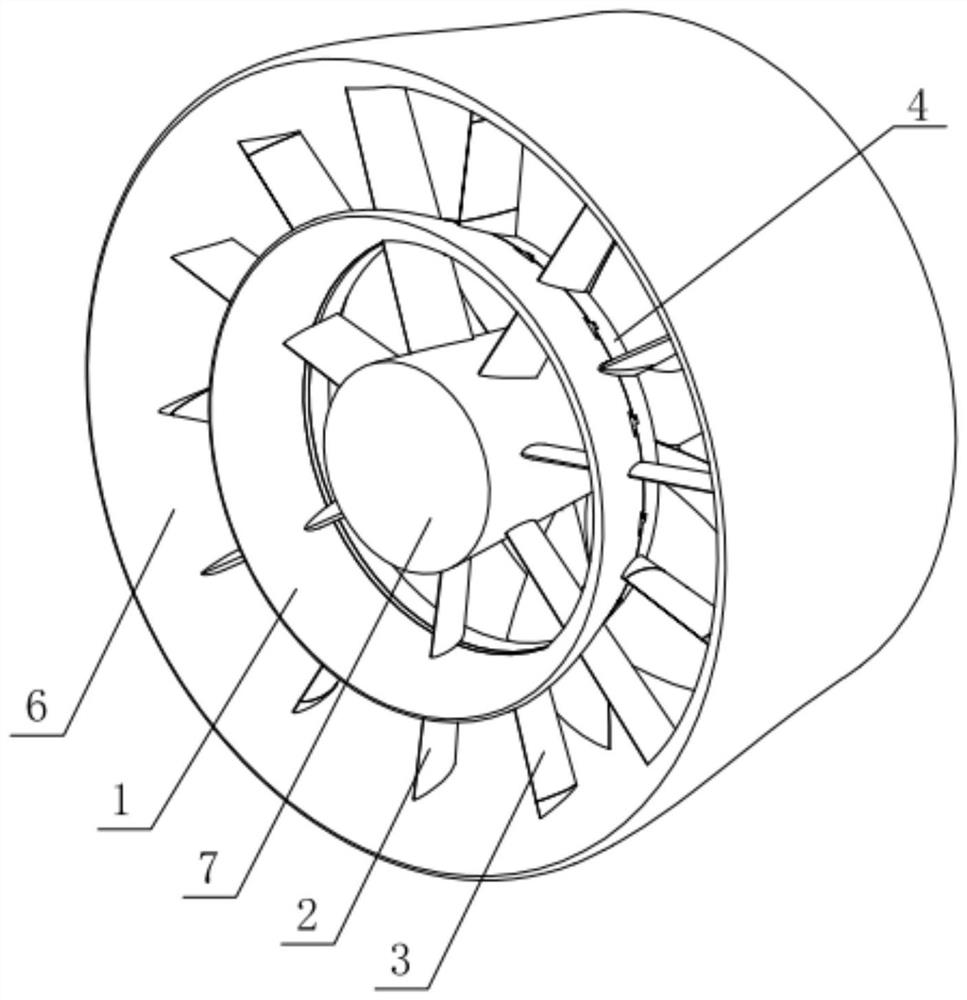

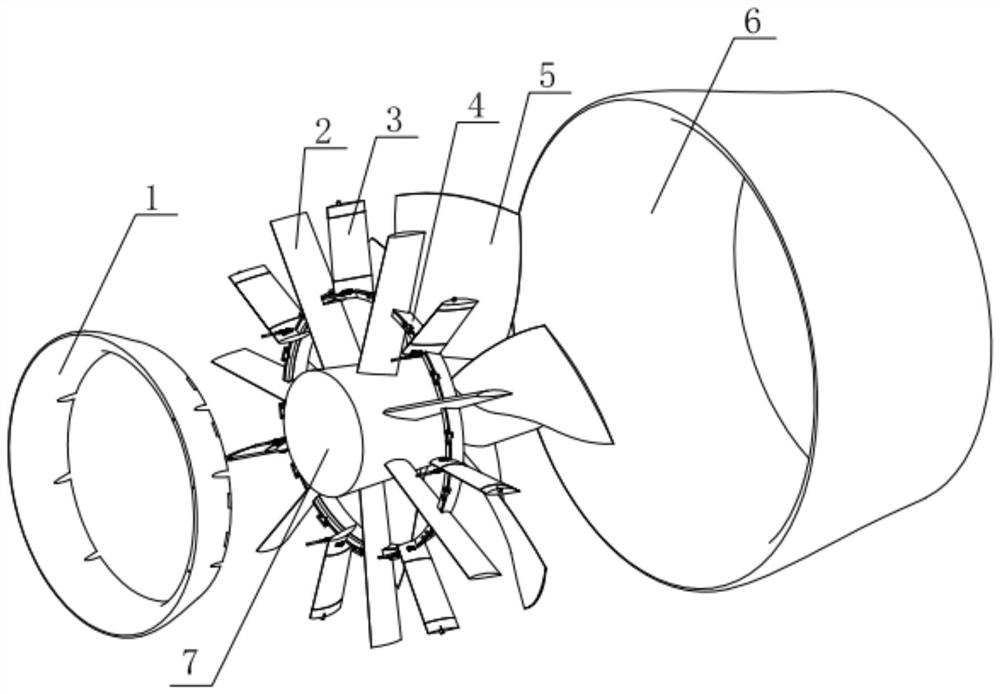

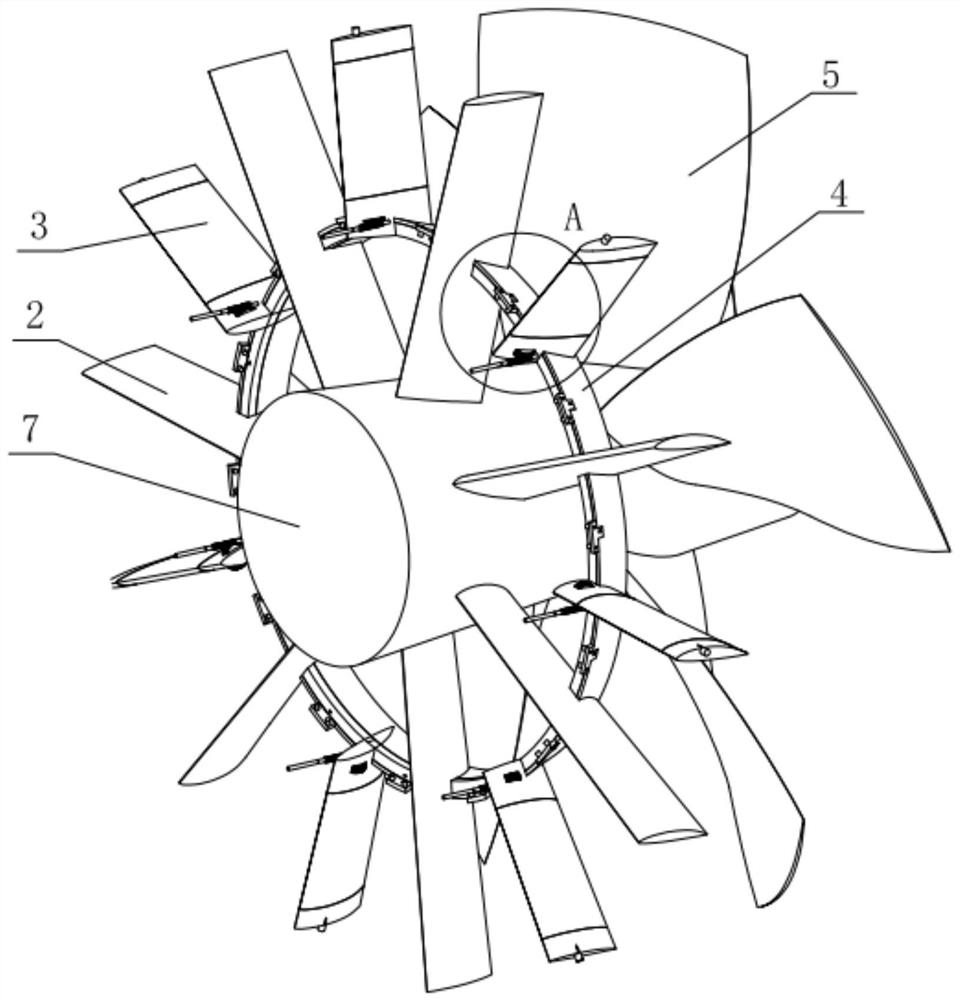

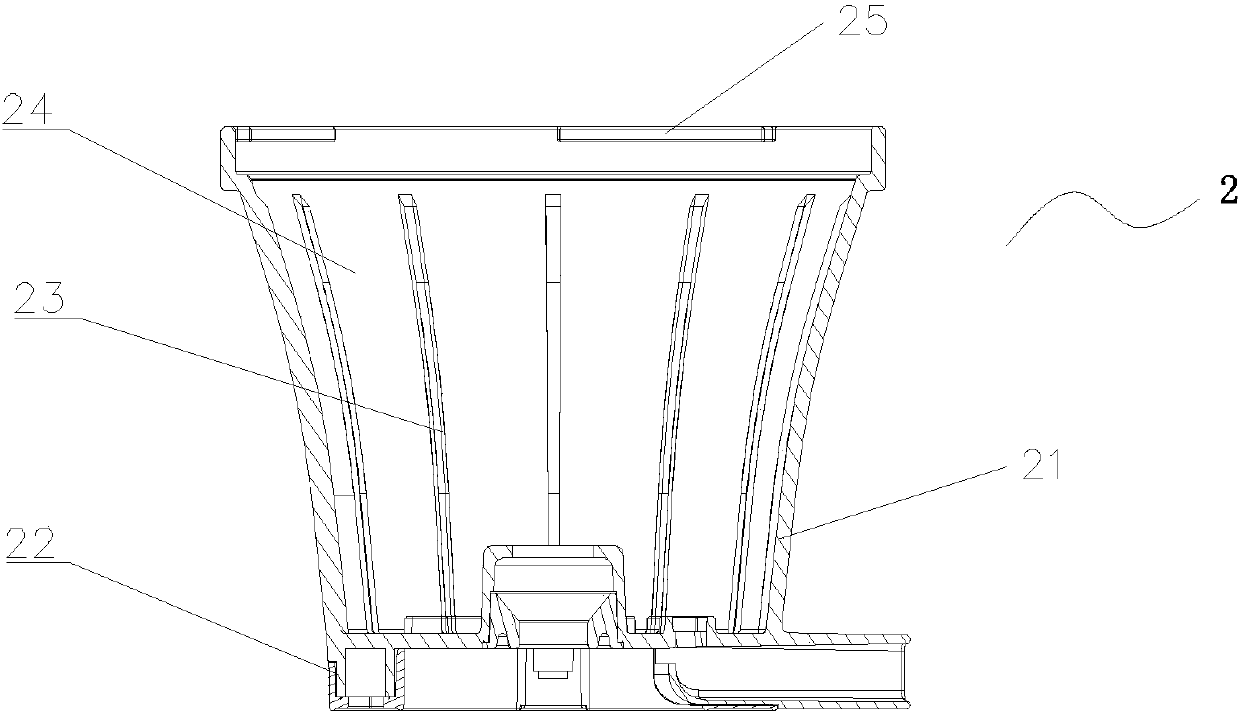

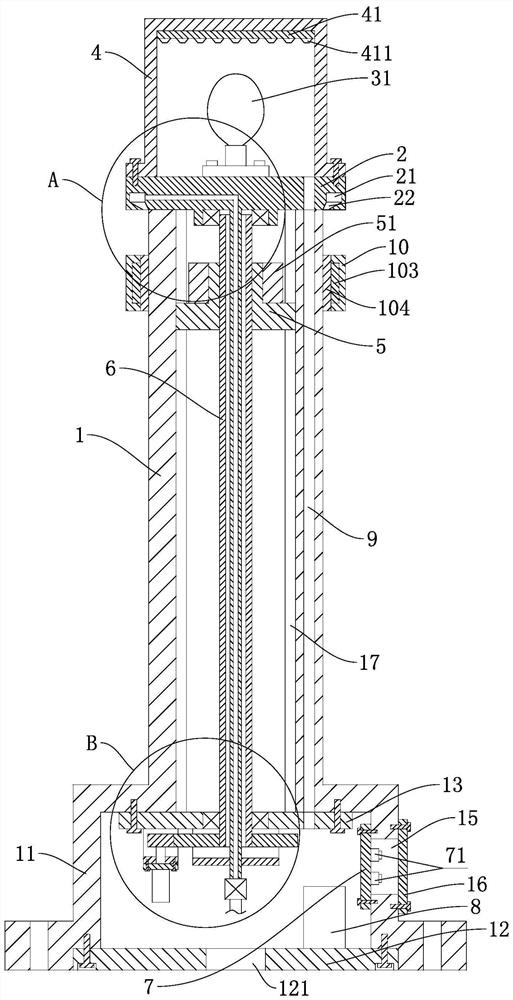

Guide pipe paddle supporting partition prewhirl flow guide device

ActiveCN111645838AImprove propulsion efficiencyImprove vibrationPropulsive elementsStructural engineeringPropulsive efficiency

The invention relates to a guide pipe paddle supporting partition prewhirl flow guide device. The device comprises a propeller hub, a plurality of propeller supports are uniformly distributed on the wall surface of the propeller hub along the circumferential direction; the outer ends of the propeller supports are jointly provided with a guide pipe, the end of a single propeller support is fixedlyconnected with the guide pipe, the middles of the propeller supports located between the propeller hub and the guide pipe are jointly provided with a flow guide ring in an embedded mode, the propellerhub, the flow guide ring and the guide pipe are axially concentric, and flow guide pieces are installed on the flow guide ring located between the adjacent propeller supports in the radial direction;the flow deflector comprises an inner guide vane and an outer guide vane which are located at the two ends, and a movable guide vane is rotationally installed between the outer guide vane and the inner guide vane. The movable guide vane is driven by the adjusting mechanism to deflect relative to the inner guide vane and the outer guide vane. By installing the prewhirl flow guide device, especially the adjustable flow guide pieces, flexible adjustment of the flow field uniformity is achieved, the propelling efficiency is improved, the vibration and cavitation performance is greatly improved, and the strength of the whole structure is effectively enhanced.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

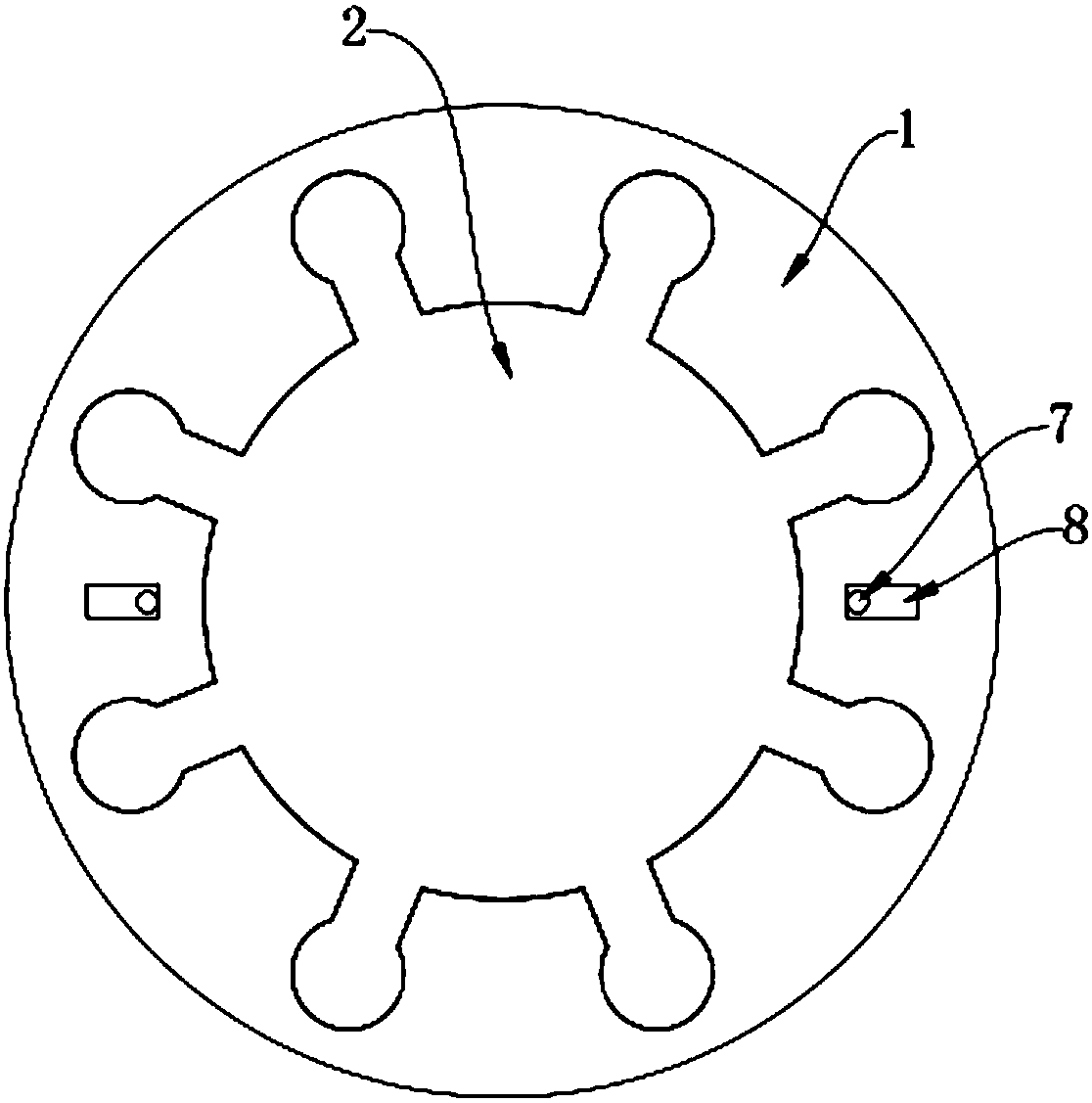

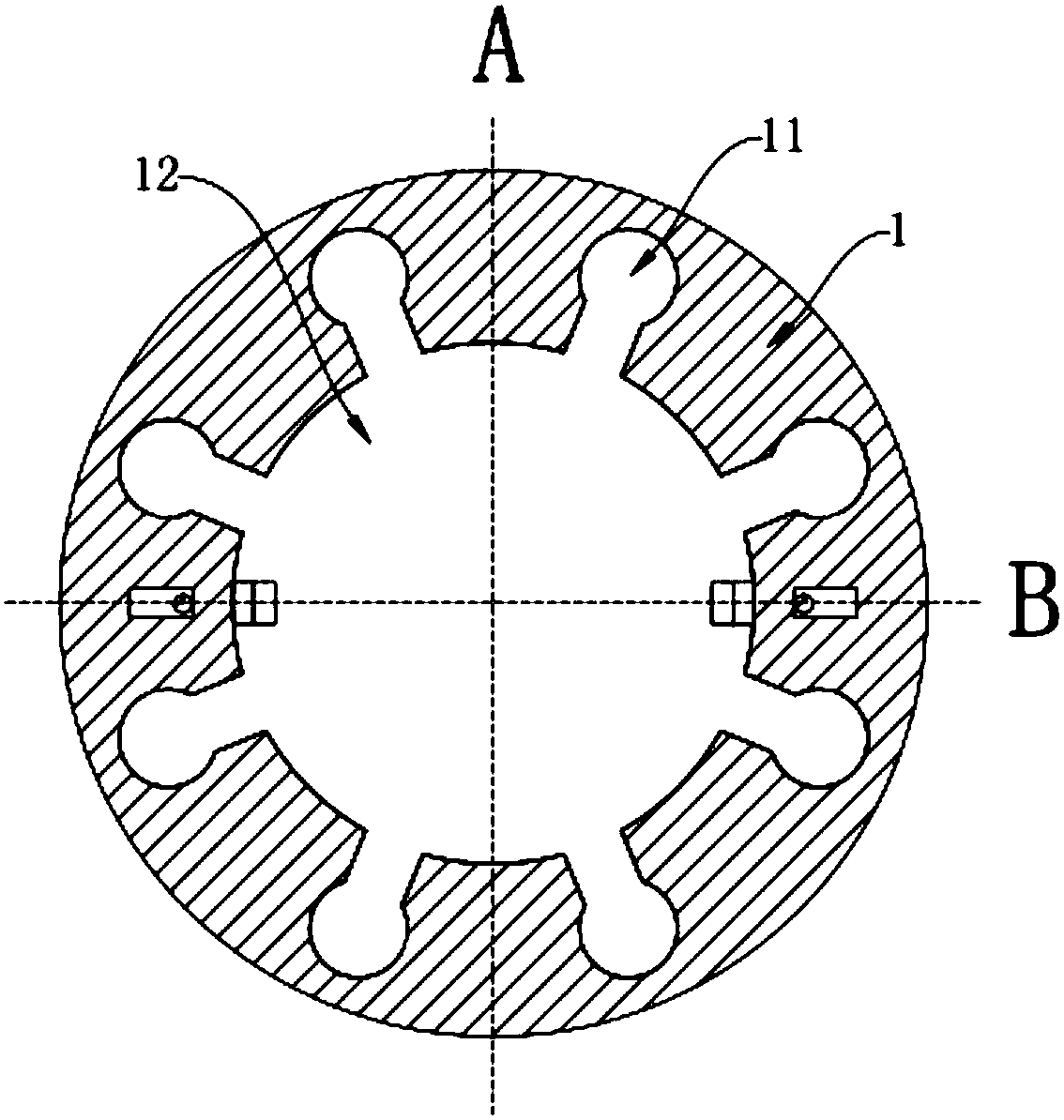

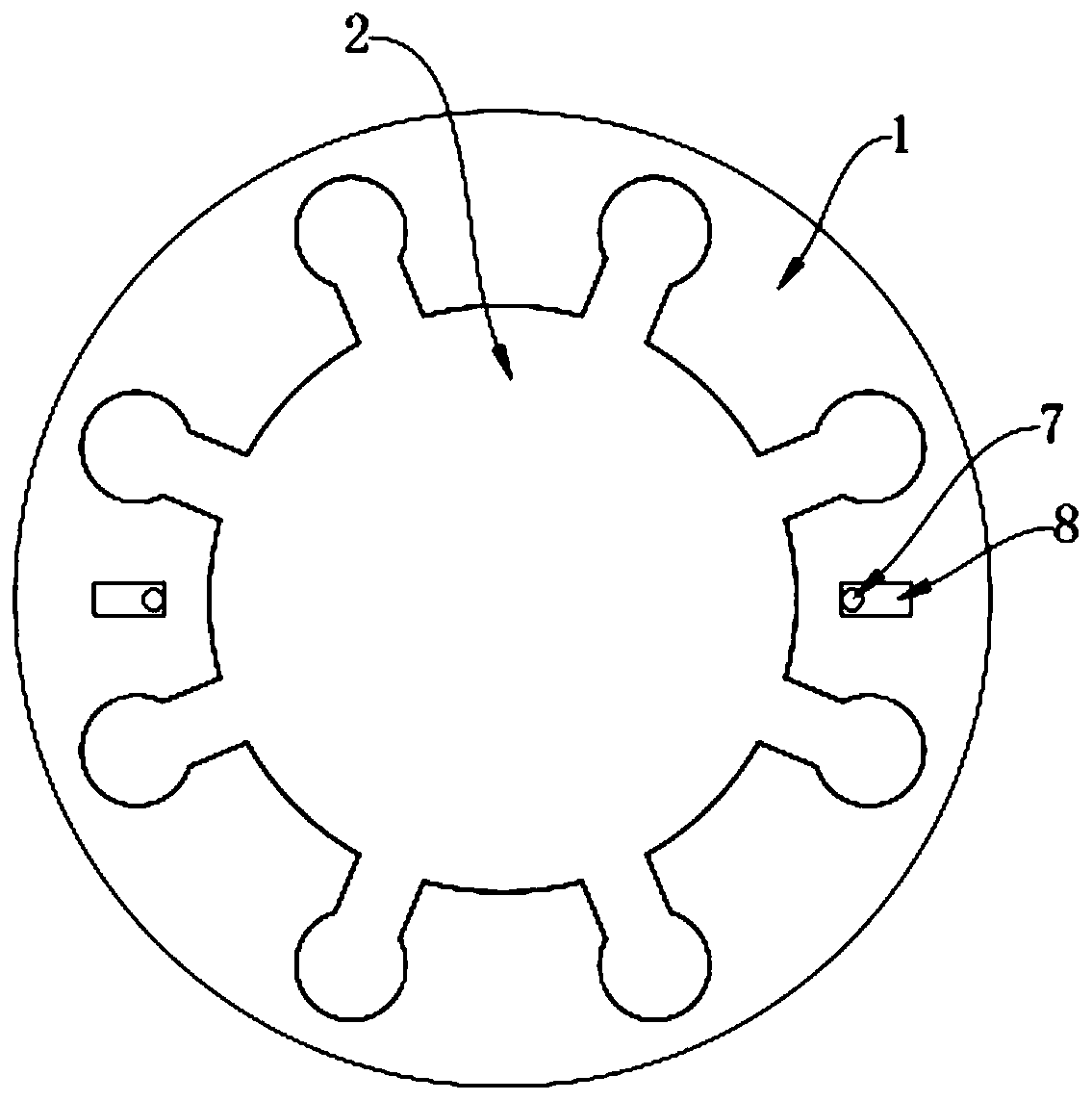

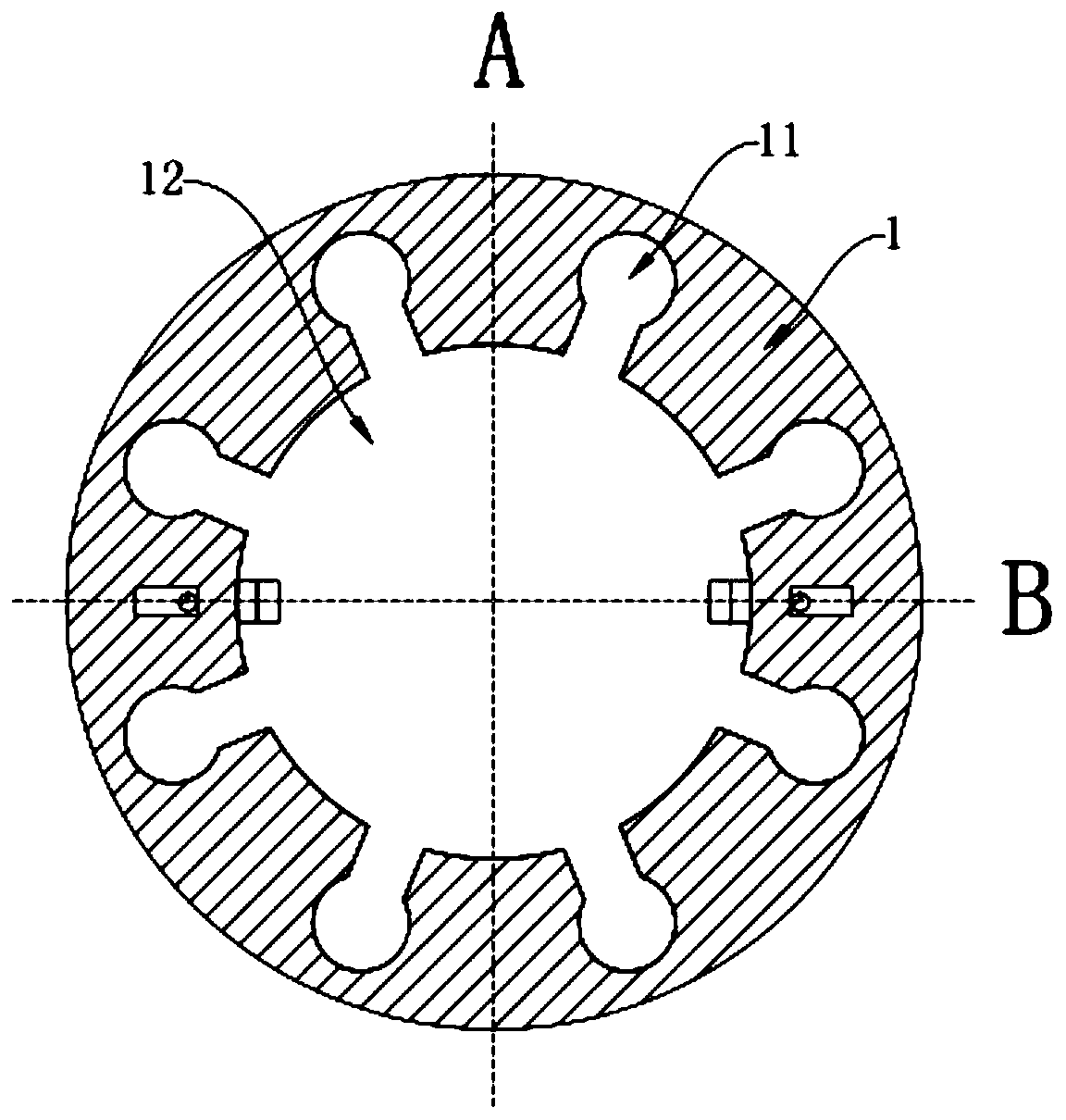

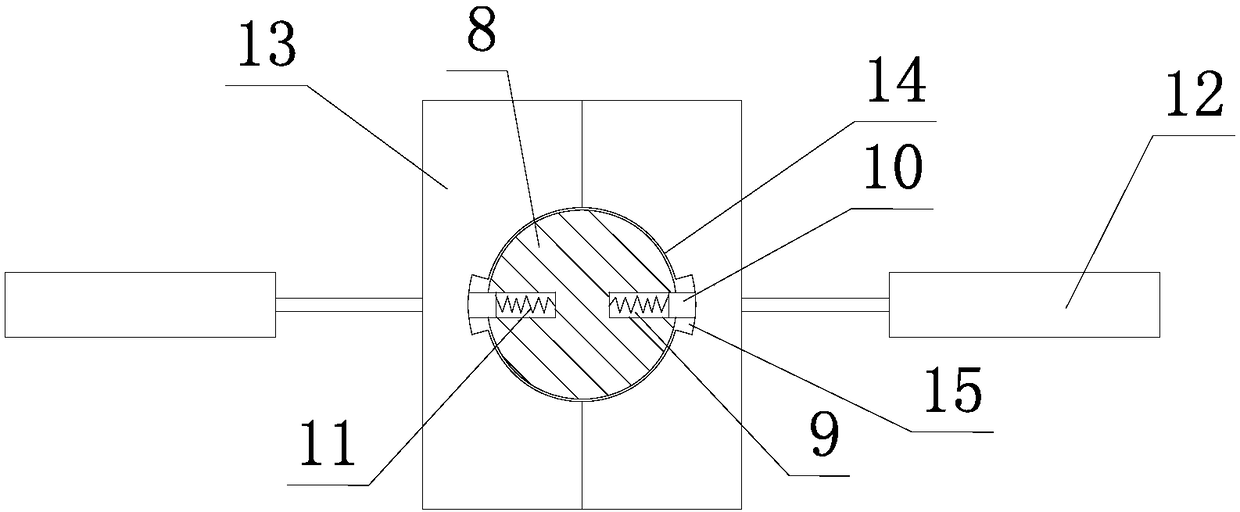

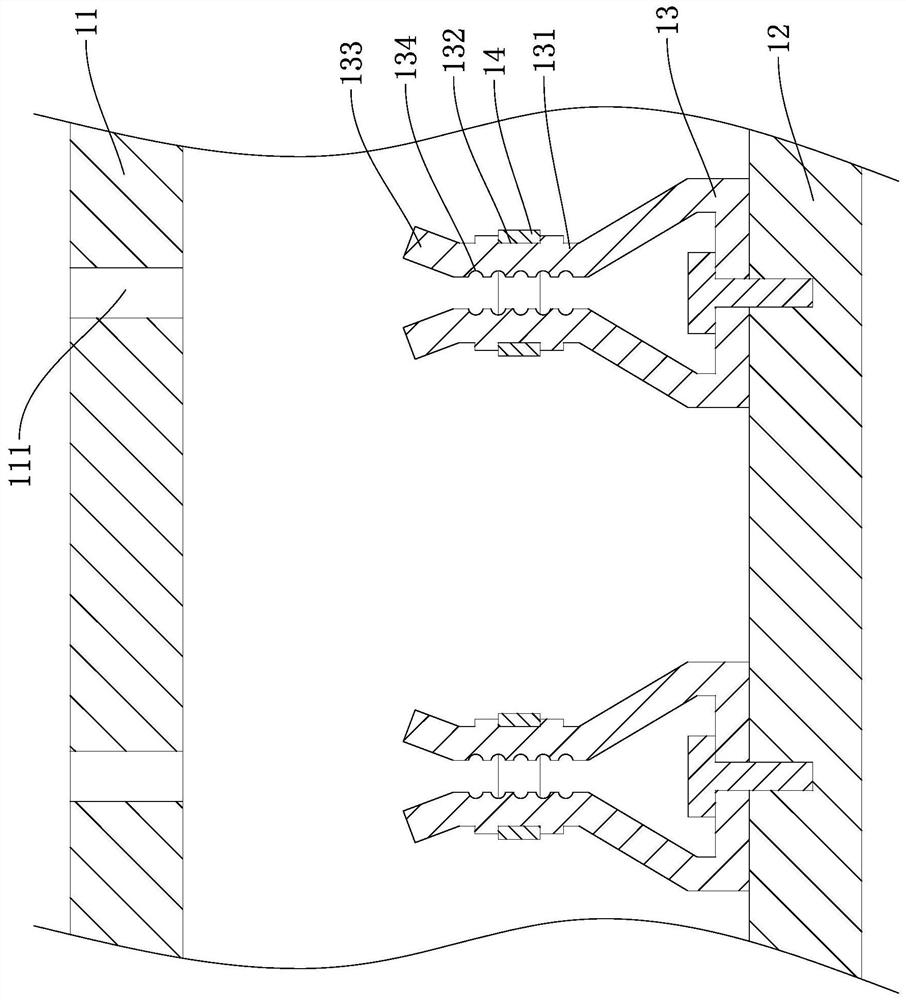

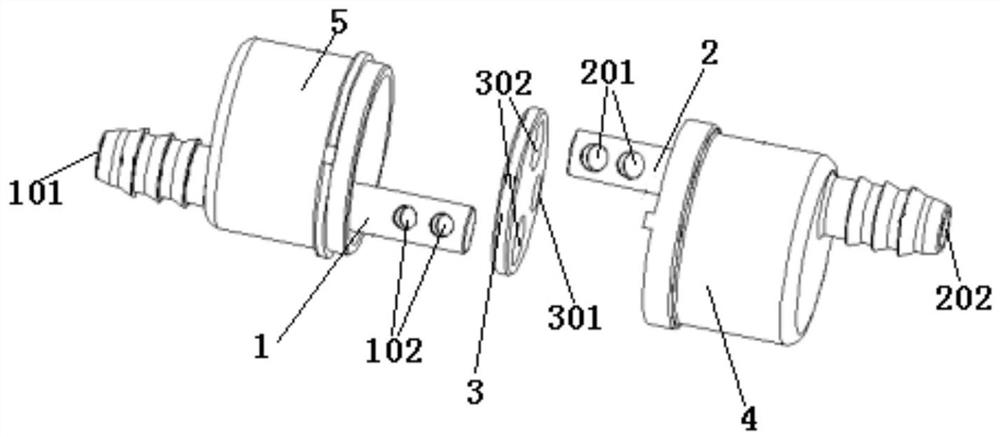

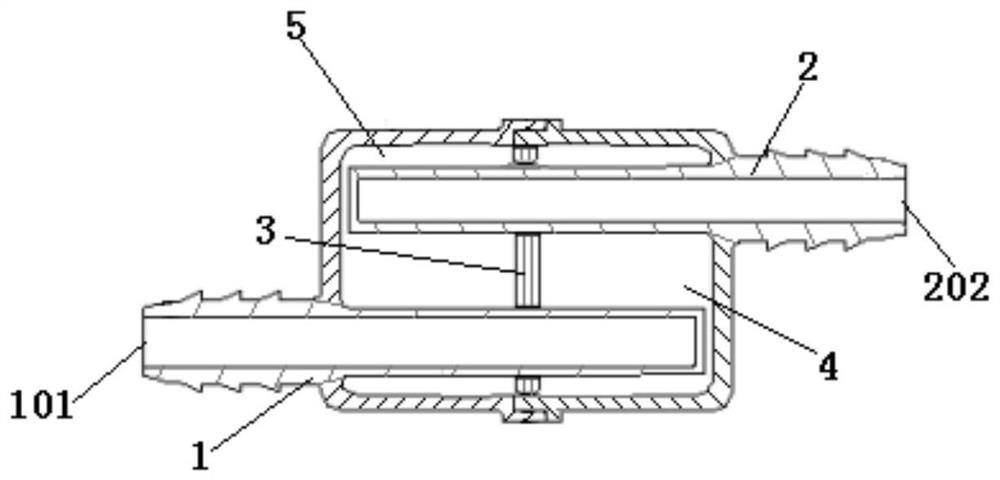

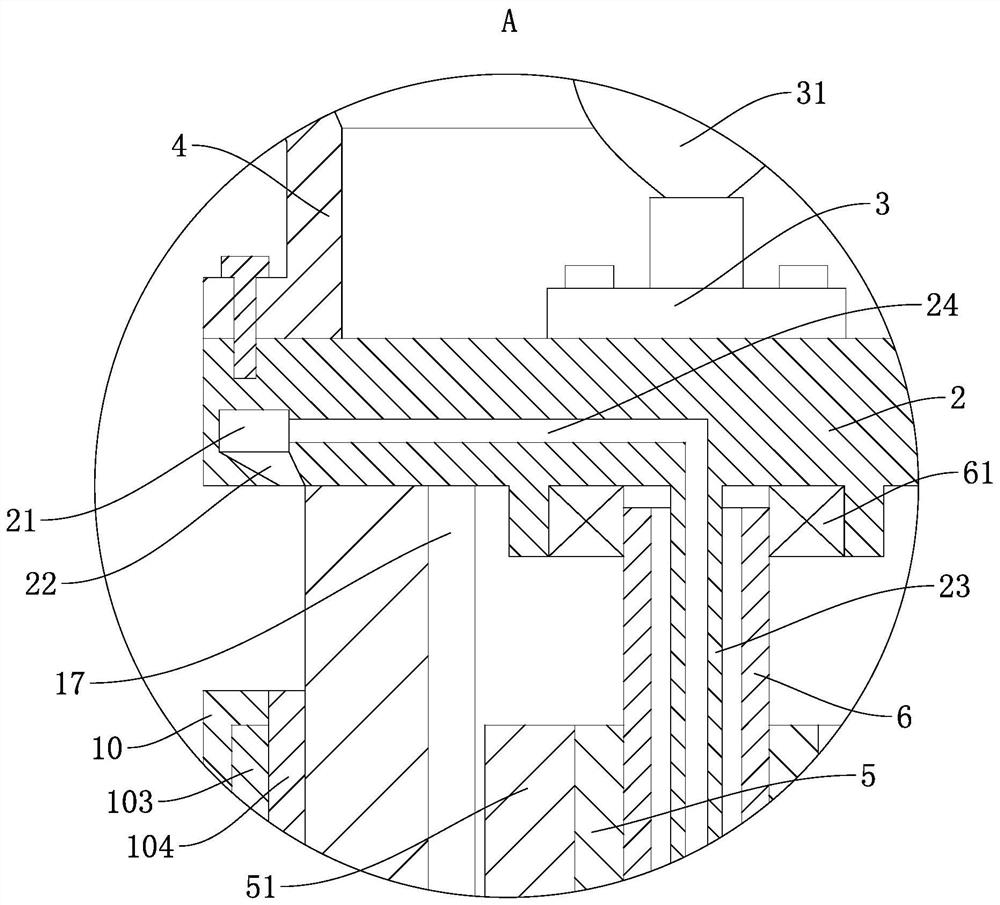

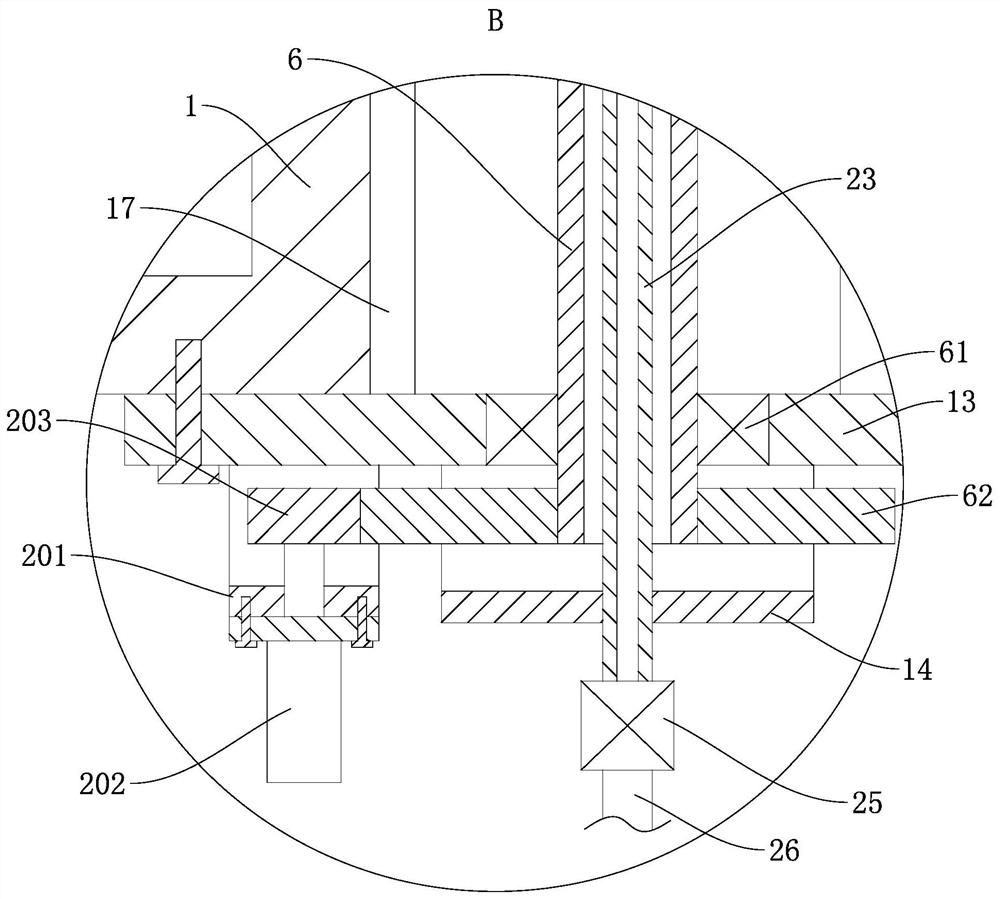

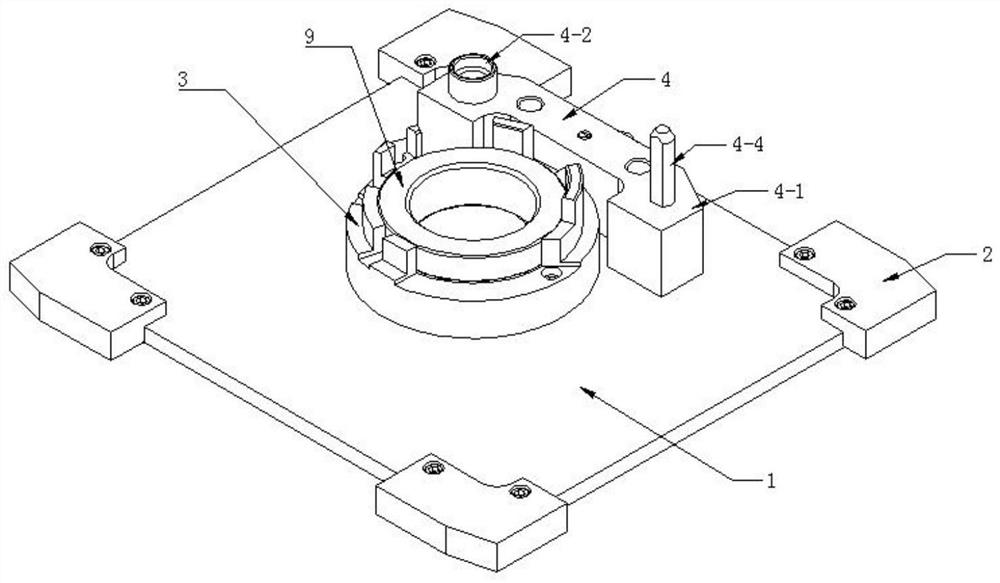

Connecting structure for motor output shaft and rotary shaft

ActiveCN107749695ATo achieve a snap connectionPrevent looseningMechanical energy handlingEngineeringMechanical equipment

The invention discloses a connecting structure for a motor output shaft and a rotary shaft. The connecting structure comprises a motor output shaft and a rotary shaft. The rotary shaft is embedded inthe motor output shaft and is provided with a plurality of bumps distributed in a radial shape along the axis of the rotary shaft. The motor output shaft is provided with a circumferential stopping slot that cooperates with the bumps. A first stopping assembly is disposed on the motor output shaft. A first groove is arranged on the rotary shaft and cooperates with the first stopping assembly. A second stopping assembly is arranged on the rotary shaft. The motor output shaft is provided with a wavy second groove arranged in the axial direction and matching the second stopping assembly. The connecting structure does not require an external connector, can directly realize the clamping connection between the motor output shaft and the rotary shaft of mechanical equipment. The axial and circumferential dual restrictions guarantee the concentricity during the assembly of the motor output shaft and the rotary shaft. The connecting structure is good in stability and avoids shaft loosening.

Owner:嘉兴市大得电器股份有限公司

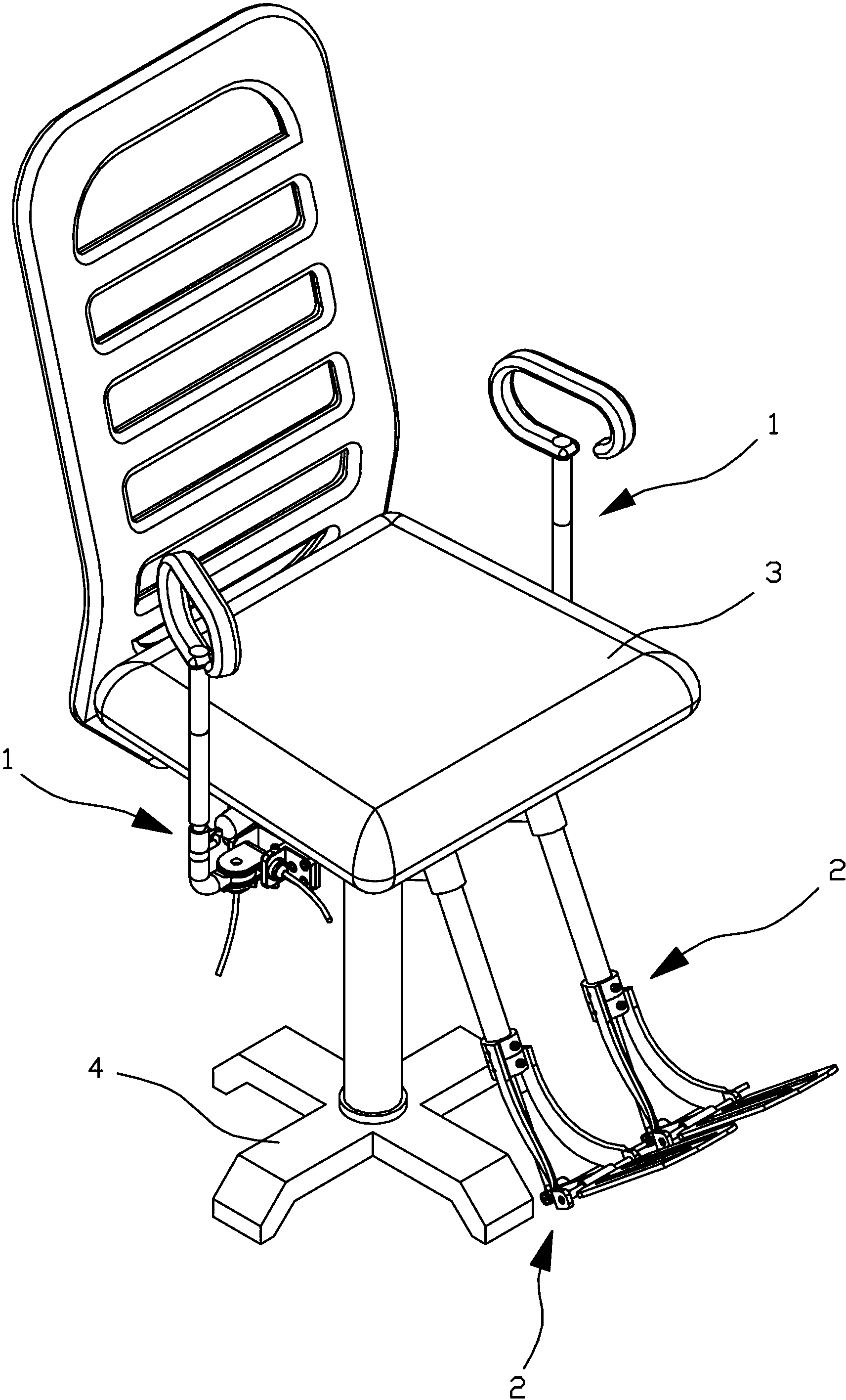

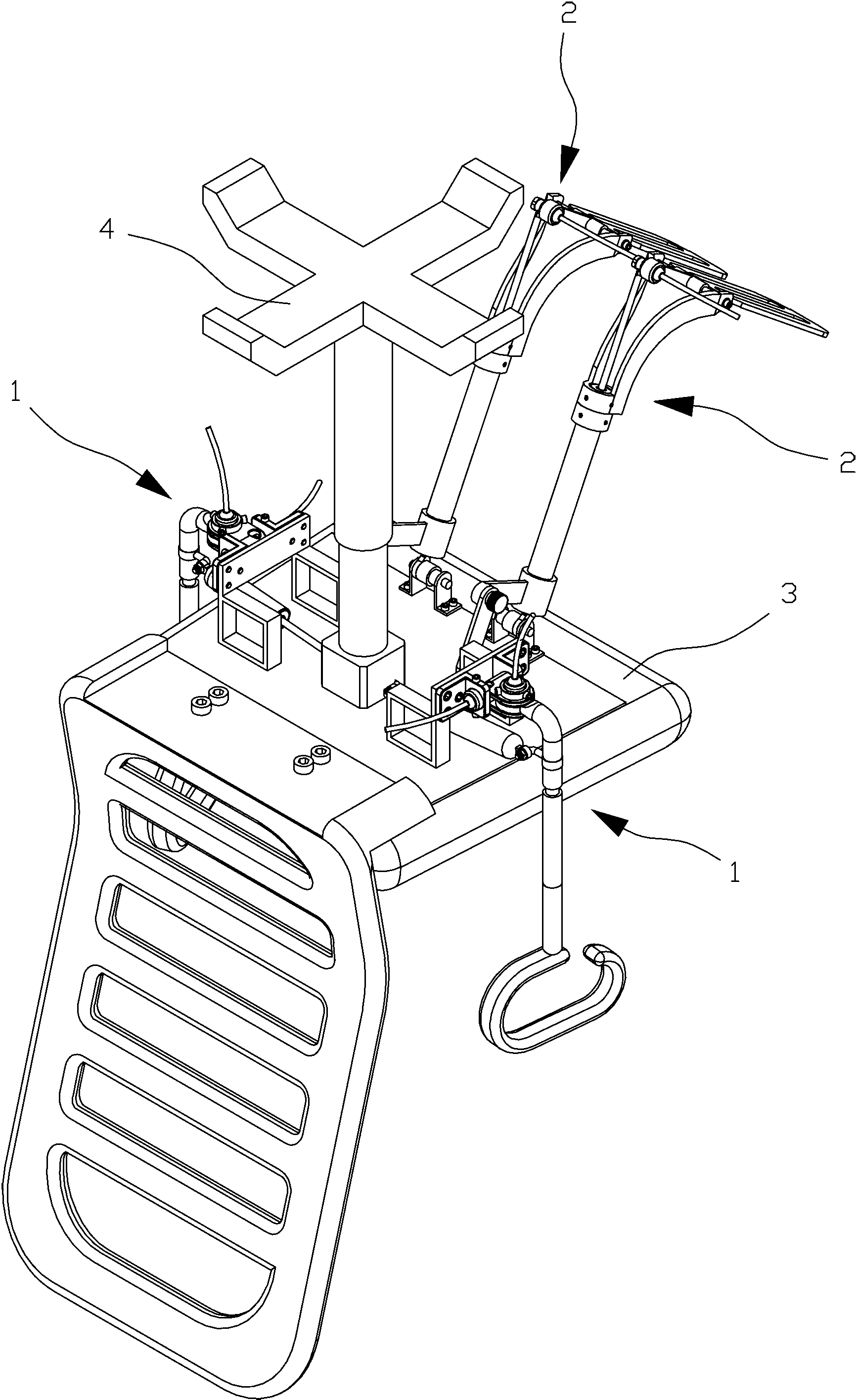

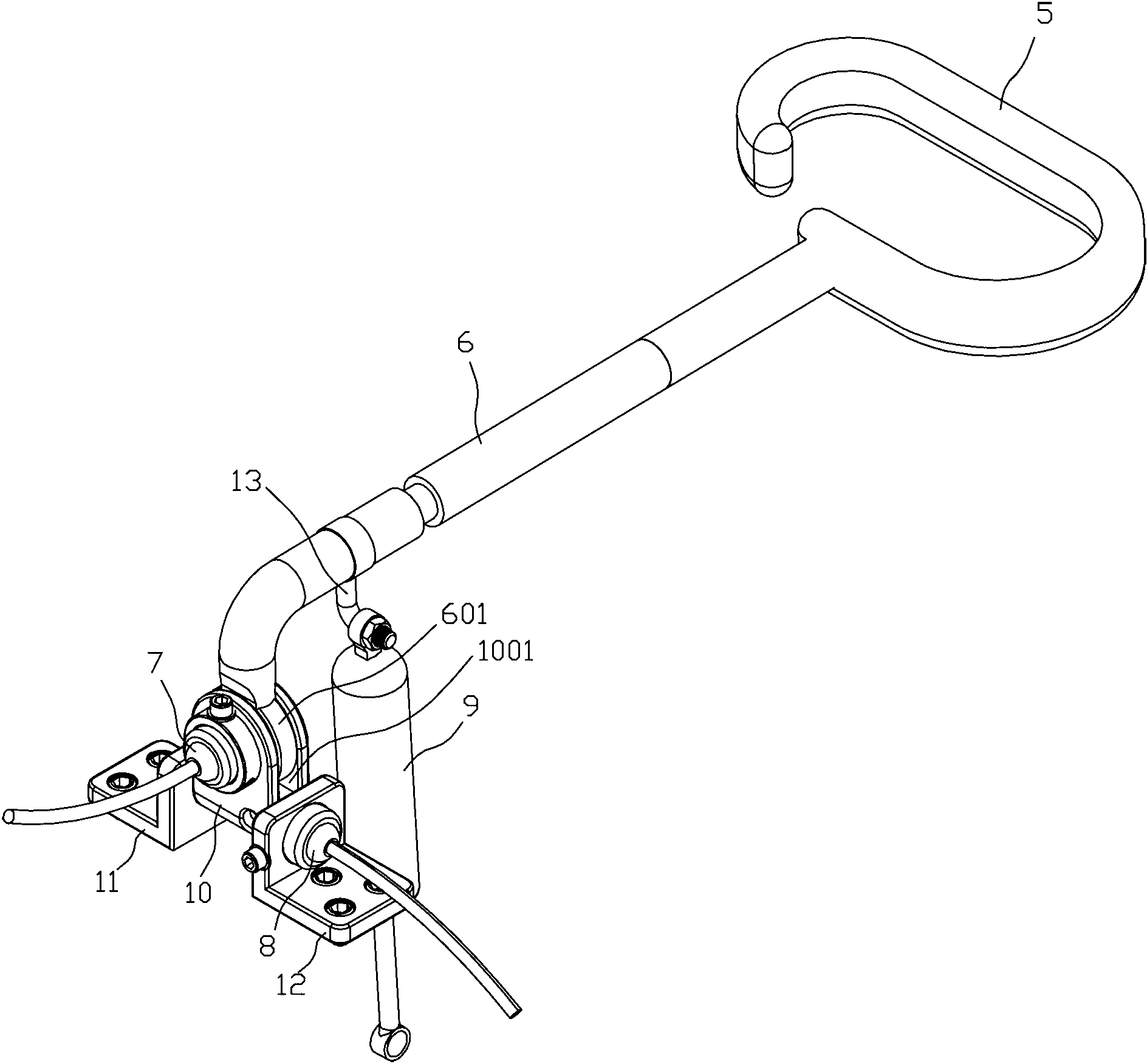

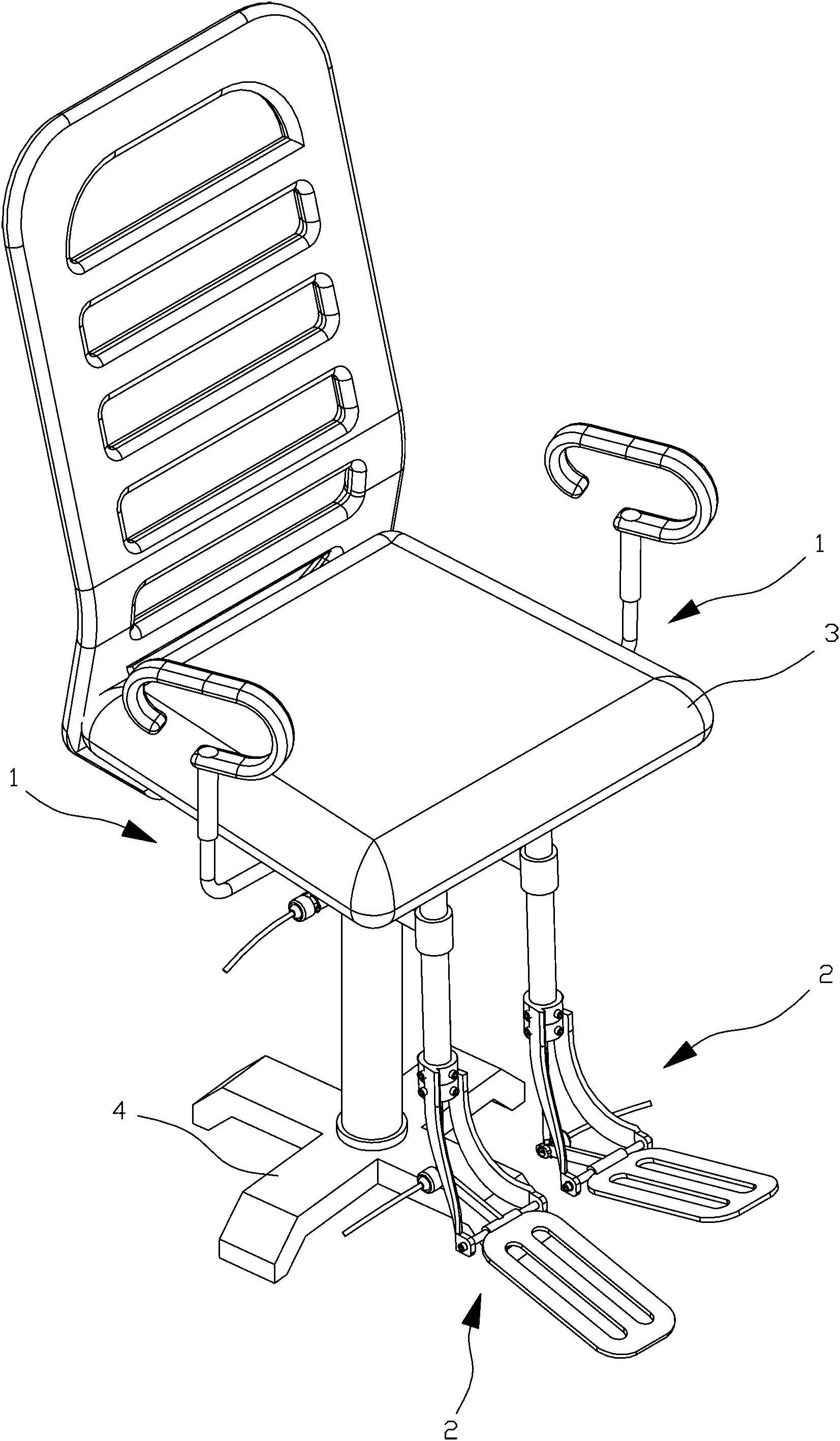

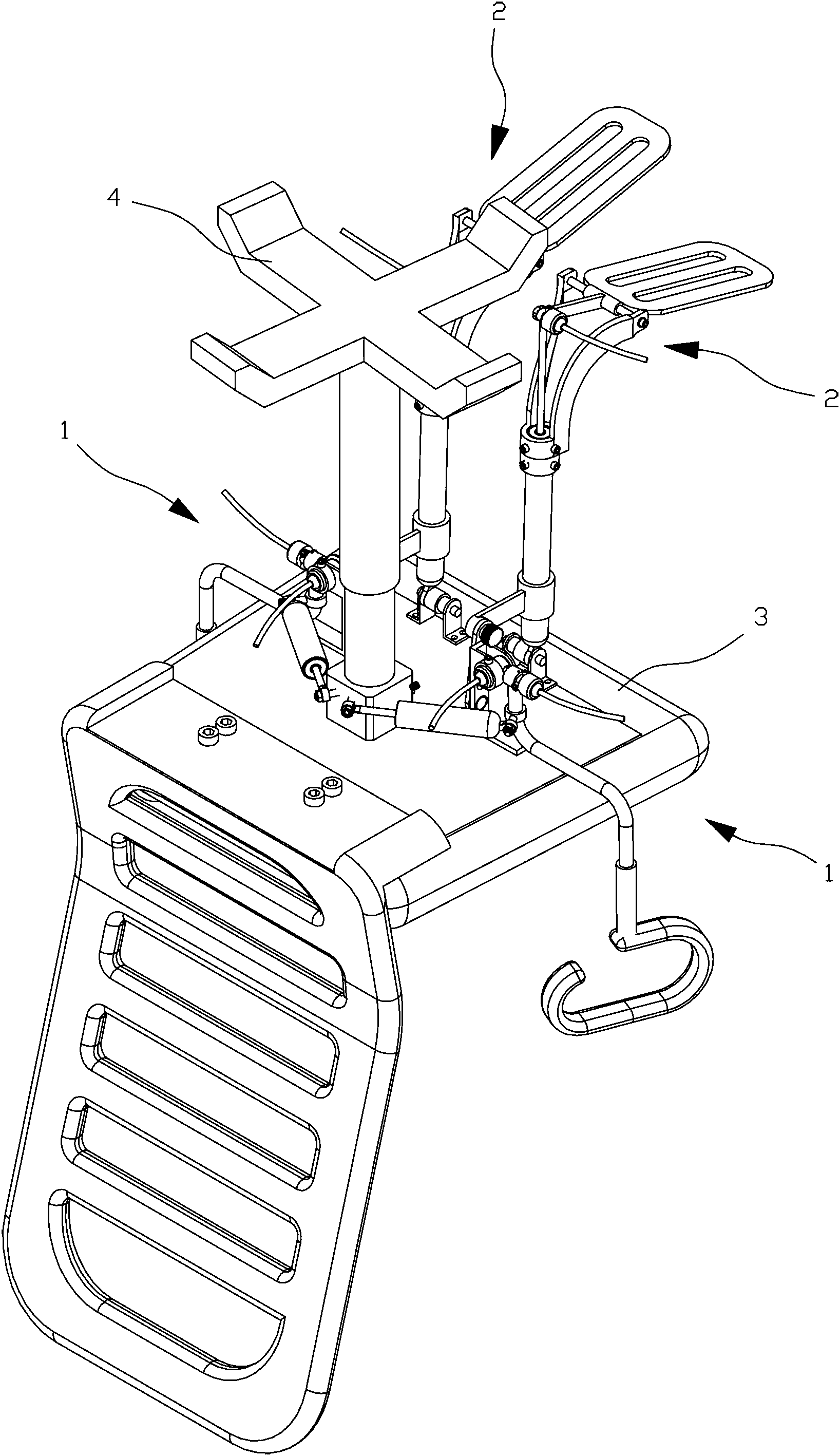

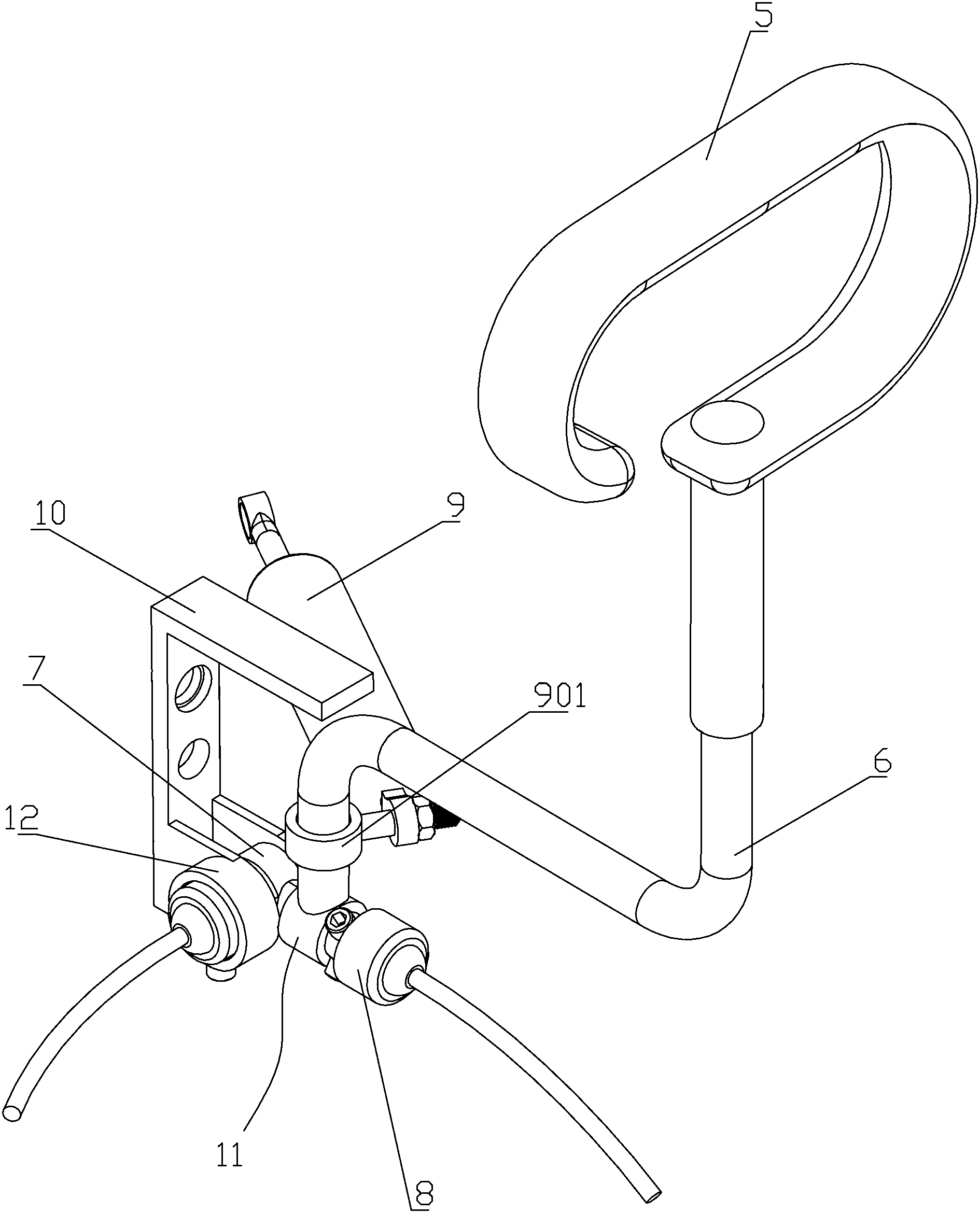

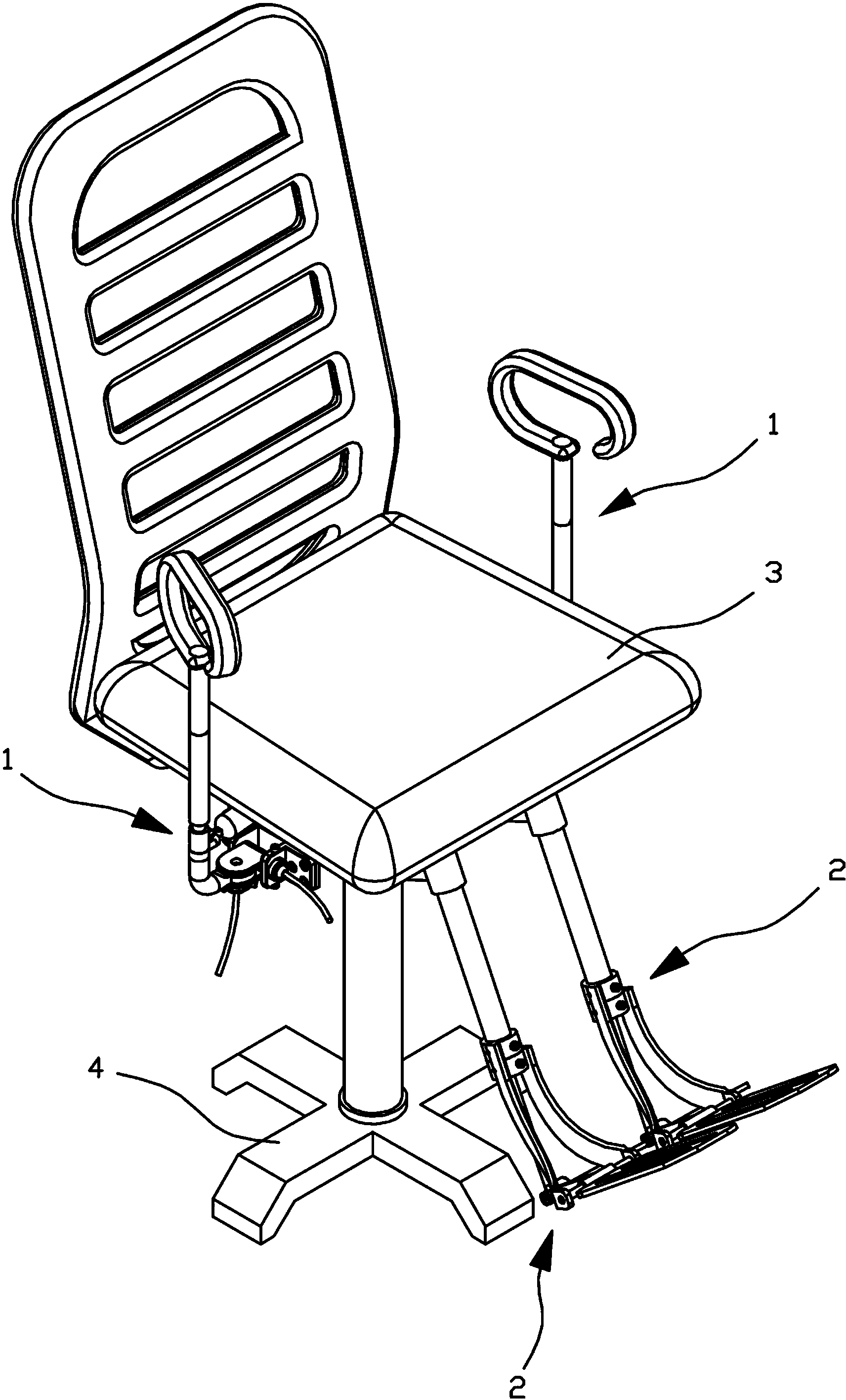

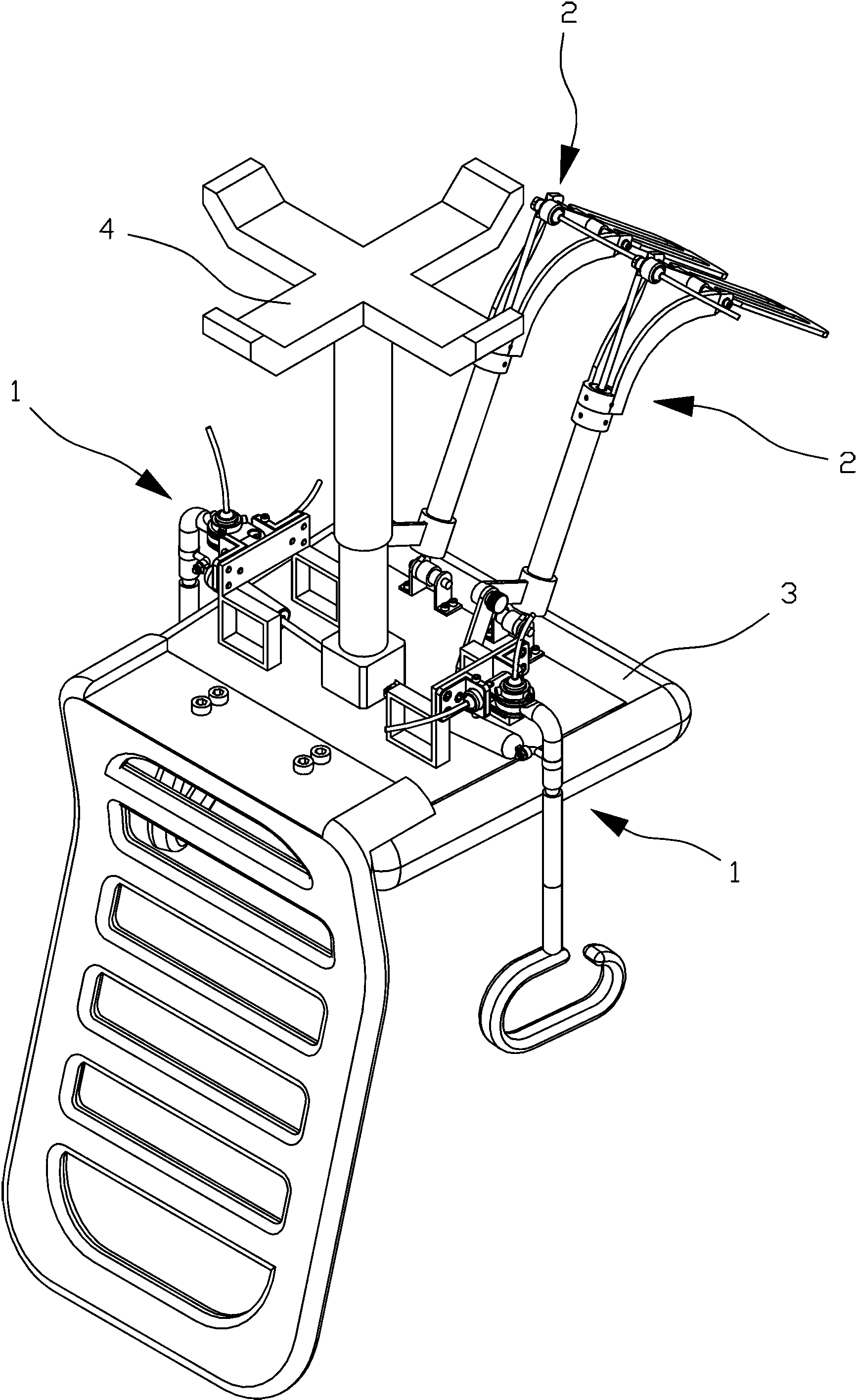

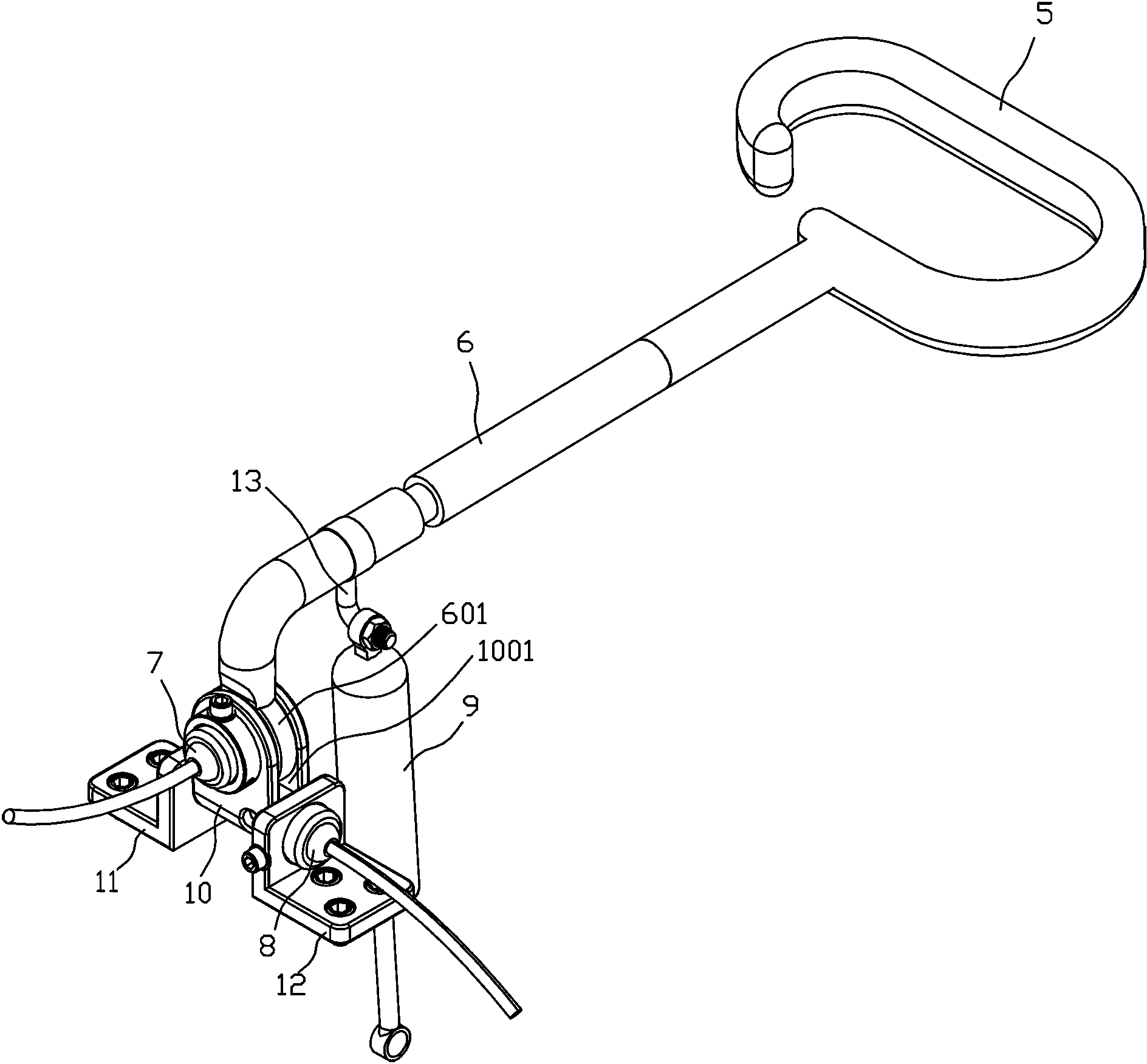

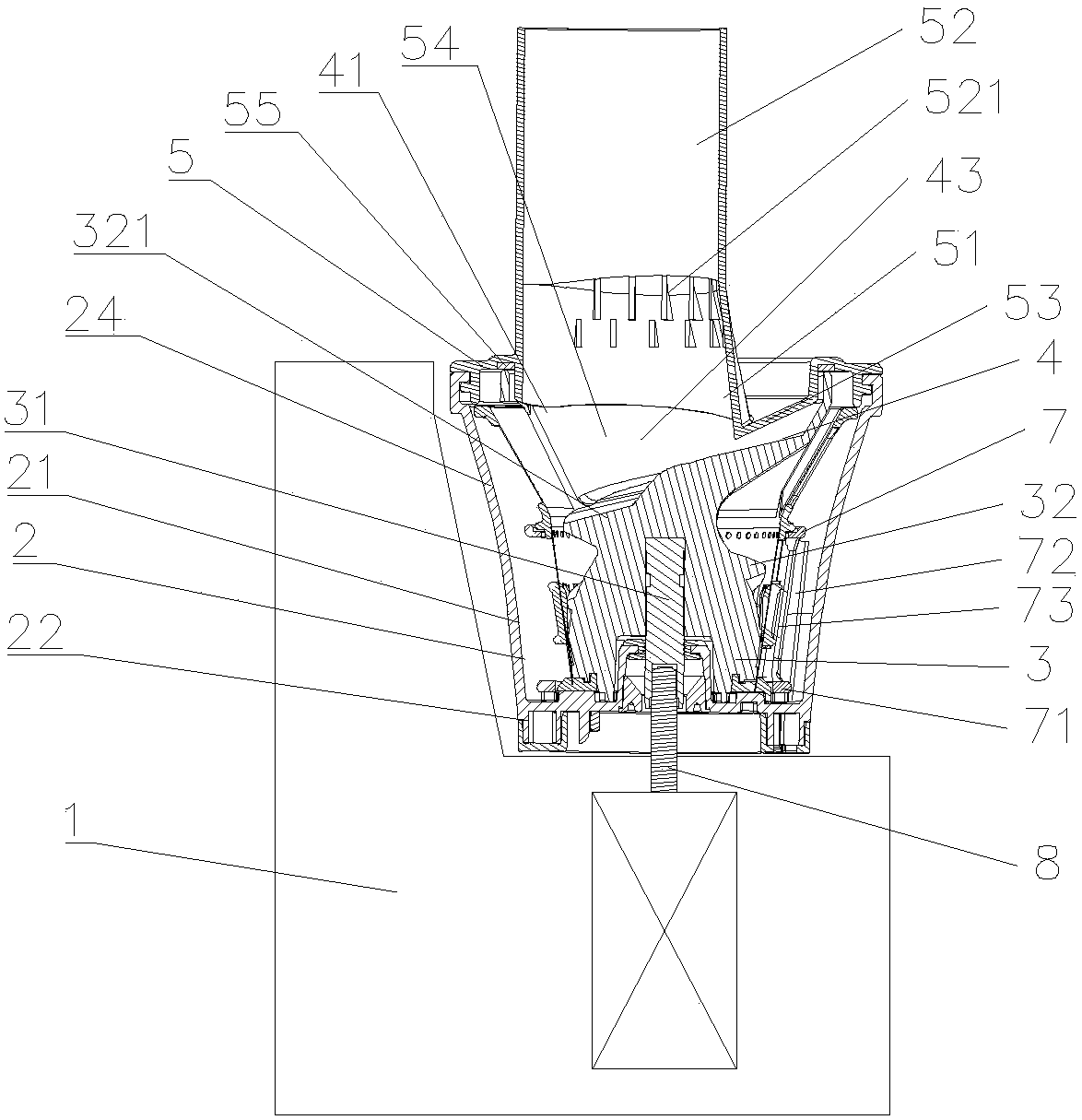

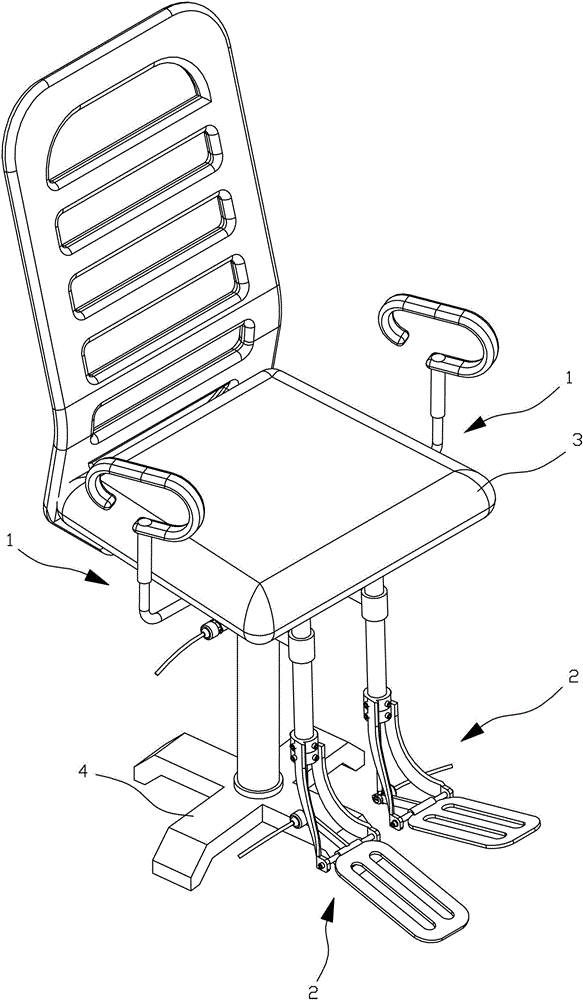

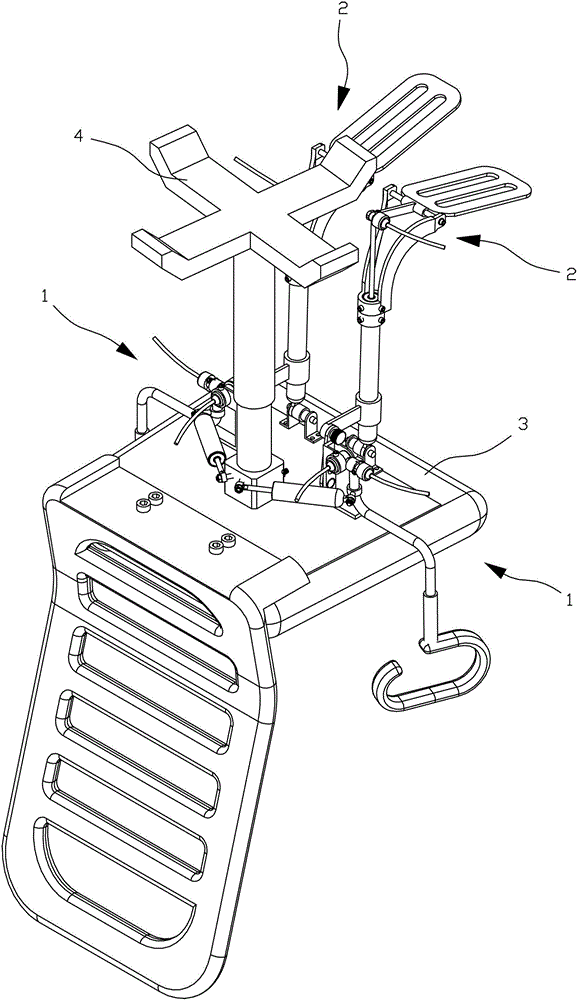

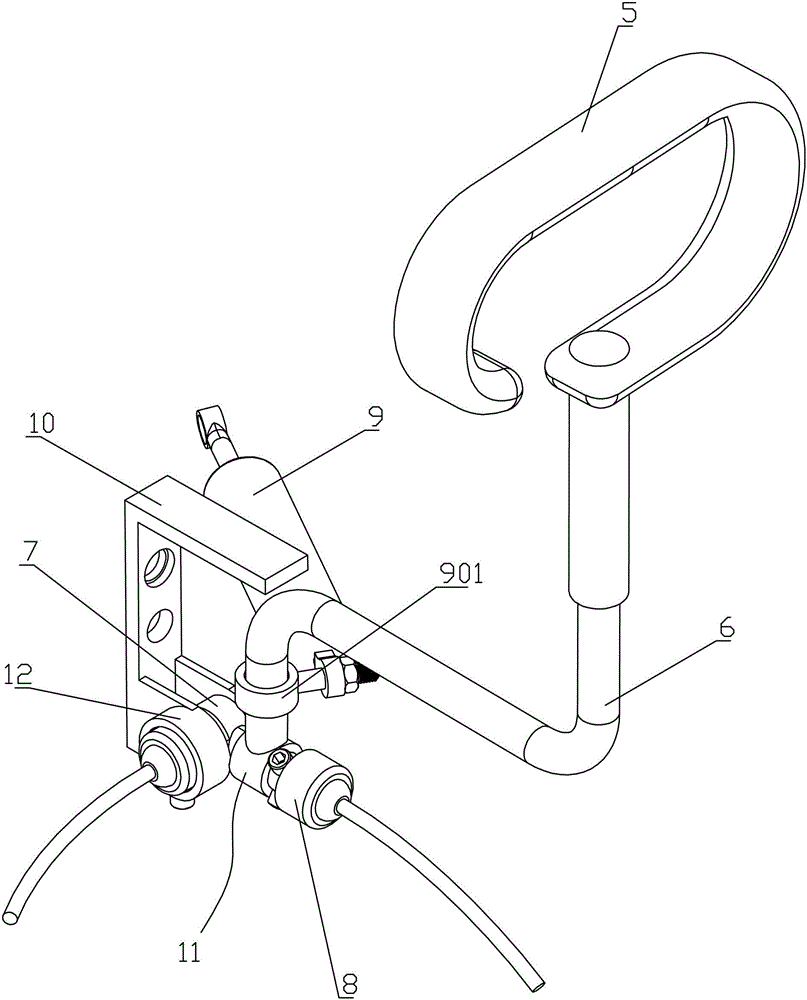

Body building chair

ActiveCN103263754AEasy to installEasy to install inMovement coordination devicesCardiovascular exercising devicesArchitectural engineeringFootplate

The invention discloses a body building chair. Two sides of a chair main body are respectively provided with a handle mechanism, two pedal mechanisms are arranged at the lower-front side of the chair main body, a first connecting rod in each handle mechanism is L-shaped, one ends of each first connecting rods are connected with handles, the other ends of the first connecting rods are hinged with an installing base, a first potentiometer is arranged on the installing base, a rotating shaft of the first potentiometer is circumferentially limited in a hinge hole in the other end of each first connecting rod, the installing base is hinged with a bracket, a second potentiometer is arranged on the bracket, a rotating shaft of the second potentiometer is circumferentially limited in a hinge hole of the installing base, support rods in each pedal mechanism comprise a first support rod and a second support rod, one ends of which are hinged and can be locked and the other ends are respectively fixed with a cylinder and the bottom of the chair main body. The body building chair is simple in structure, larger in angle for which the handles can be oscillated, and capable of regulating the height of pedals.

Owner:南通江海港建设工程有限公司

A connection structure for motor output shaft and rotating shaft

ActiveCN107749695BTo achieve a snap connectionPrevent looseningMechanical energy handlingRotational axisElectric machinery

The invention discloses a connecting structure for a motor output shaft and a rotary shaft. The connecting structure comprises a motor output shaft and a rotary shaft. The rotary shaft is embedded inthe motor output shaft and is provided with a plurality of bumps distributed in a radial shape along the axis of the rotary shaft. The motor output shaft is provided with a circumferential stopping slot that cooperates with the bumps. A first stopping assembly is disposed on the motor output shaft. A first groove is arranged on the rotary shaft and cooperates with the first stopping assembly. A second stopping assembly is arranged on the rotary shaft. The motor output shaft is provided with a wavy second groove arranged in the axial direction and matching the second stopping assembly. The connecting structure does not require an external connector, can directly realize the clamping connection between the motor output shaft and the rotary shaft of mechanical equipment. The axial and circumferential dual restrictions guarantee the concentricity during the assembly of the motor output shaft and the rotary shaft. The connecting structure is good in stability and avoids shaft loosening.

Owner:嘉兴市大得电器股份有限公司

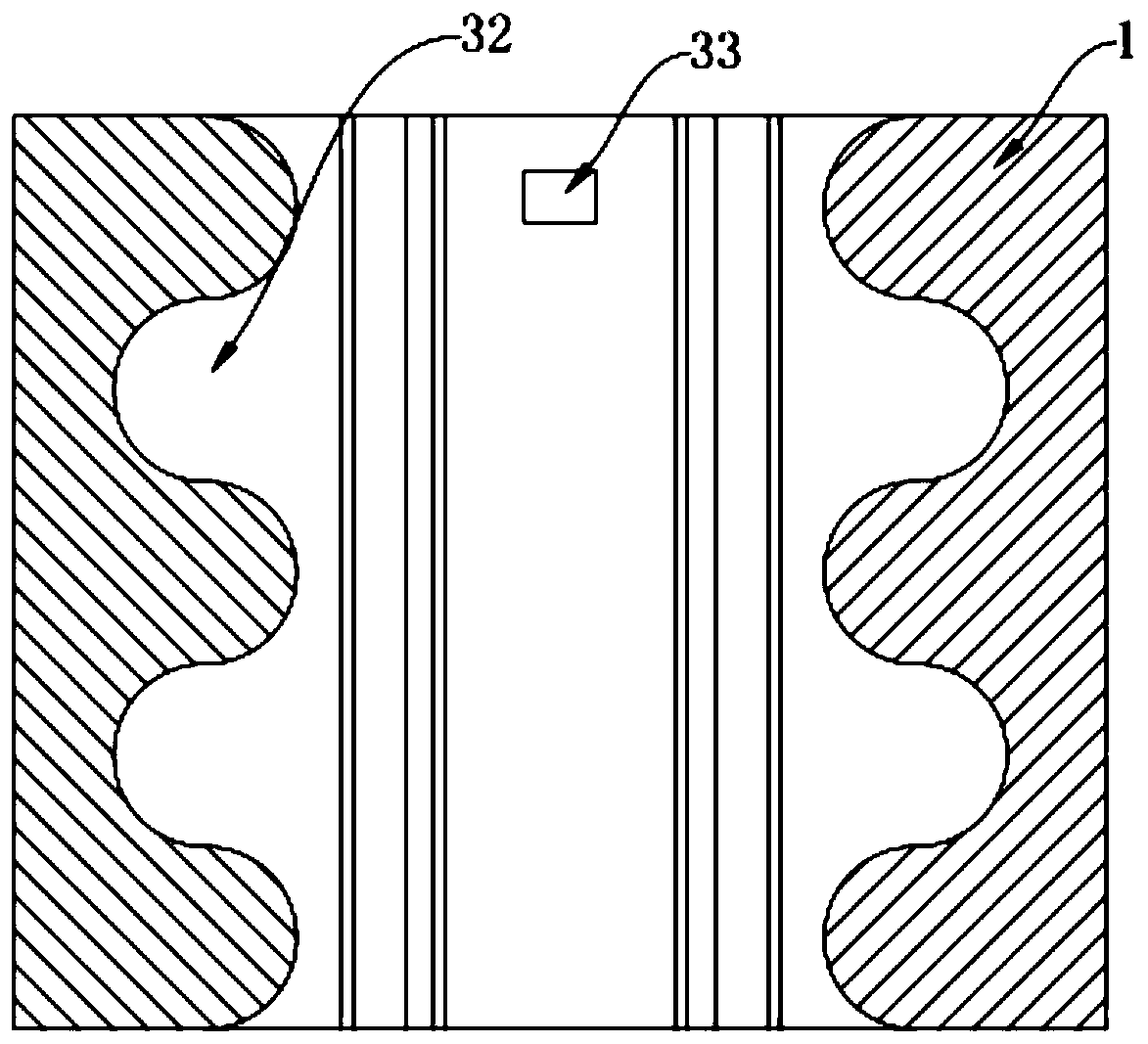

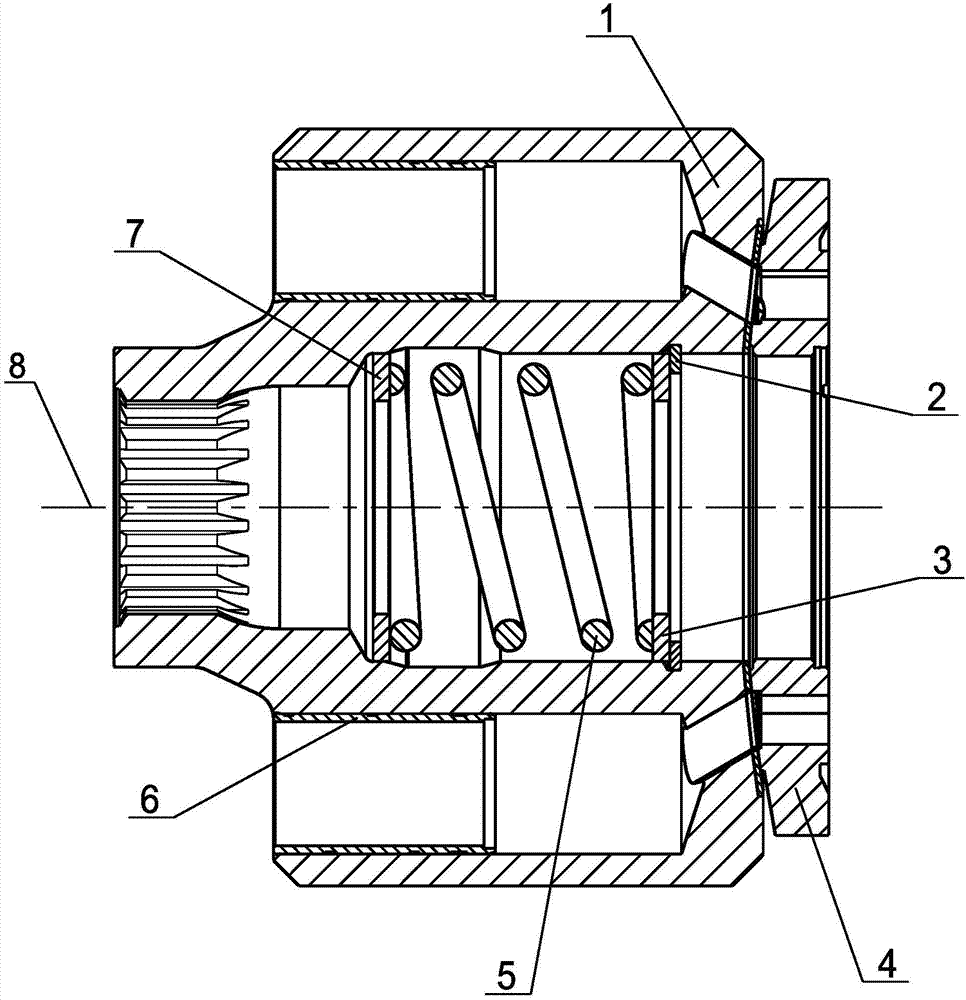

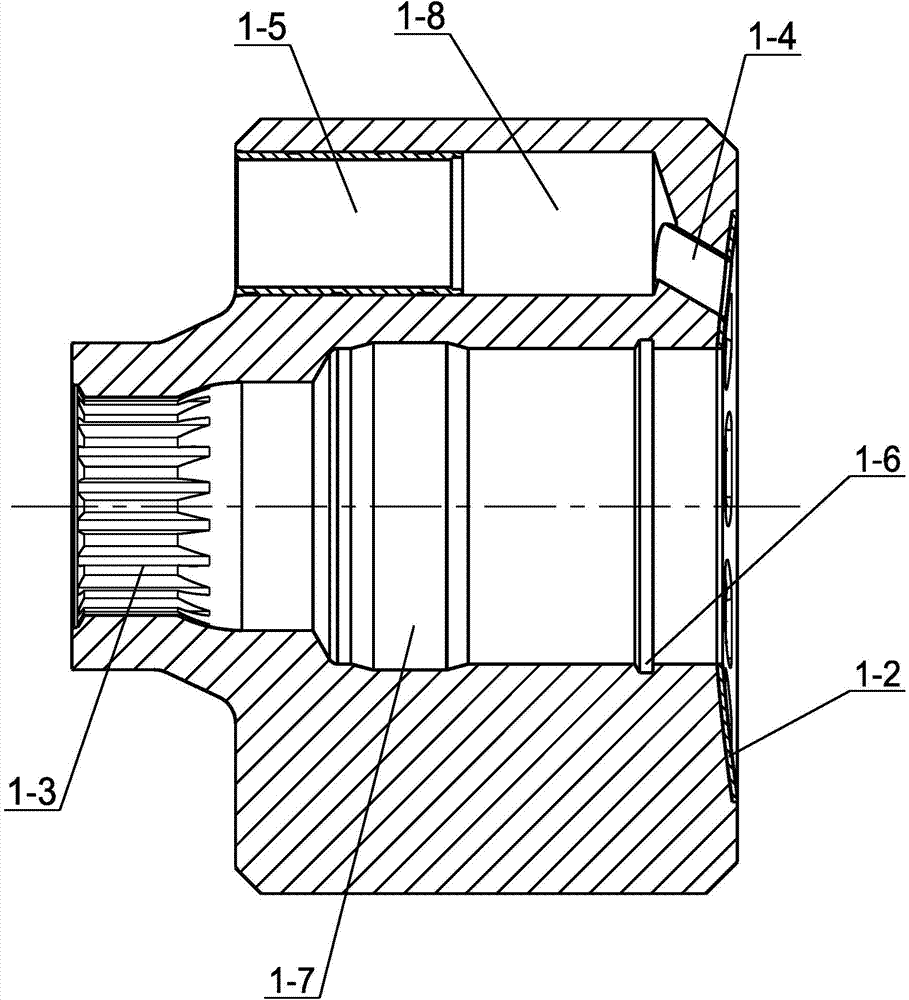

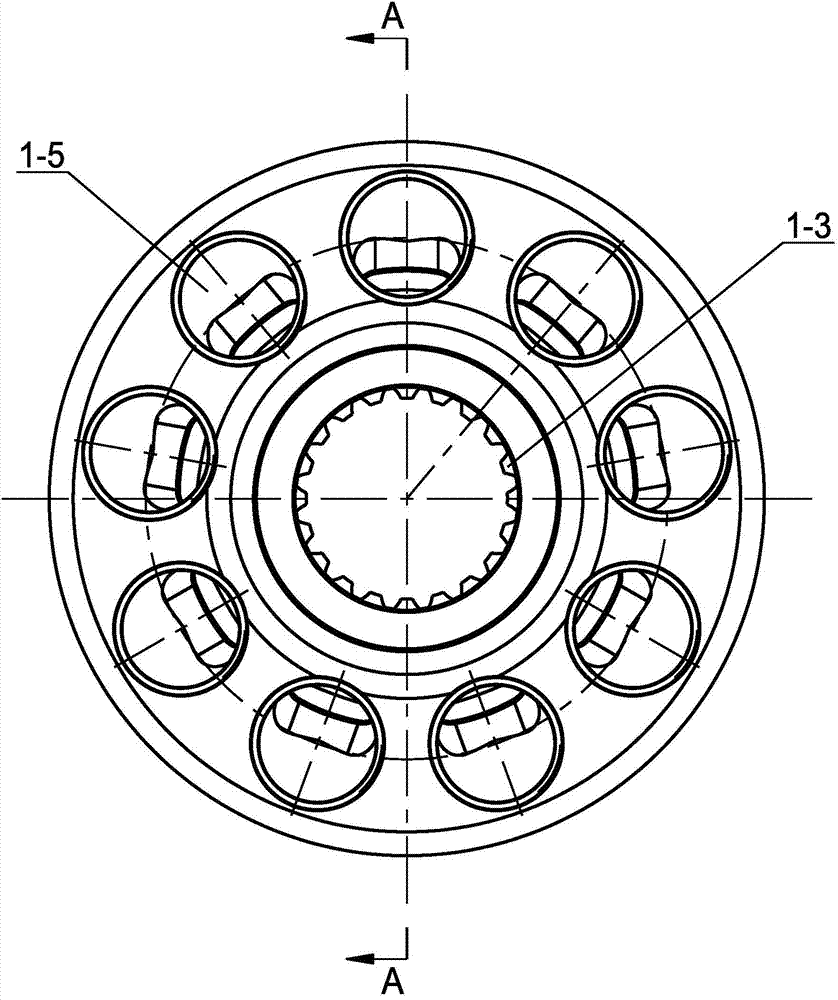

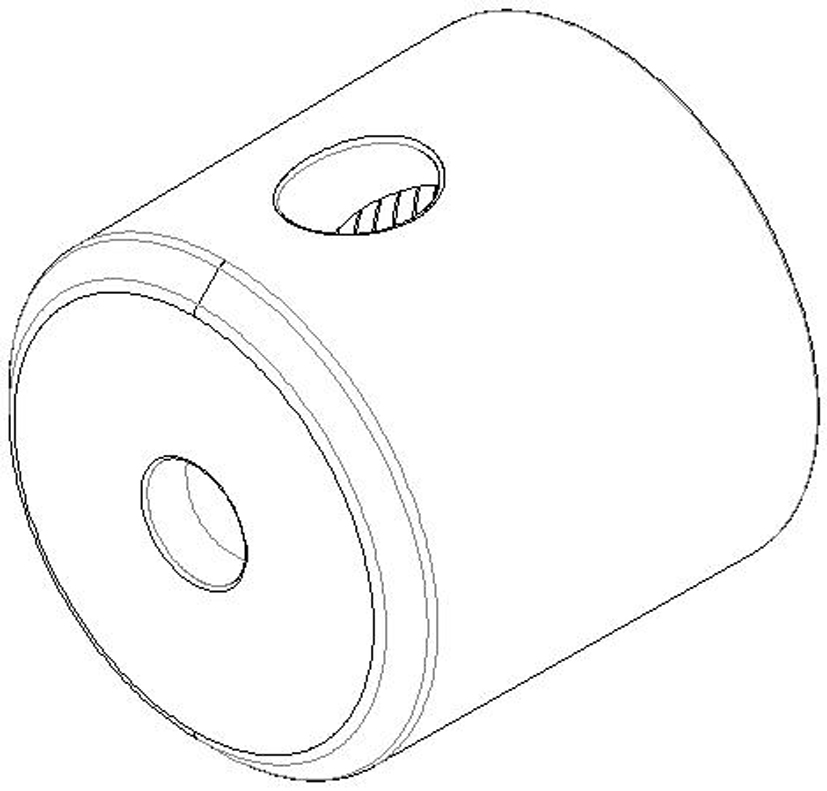

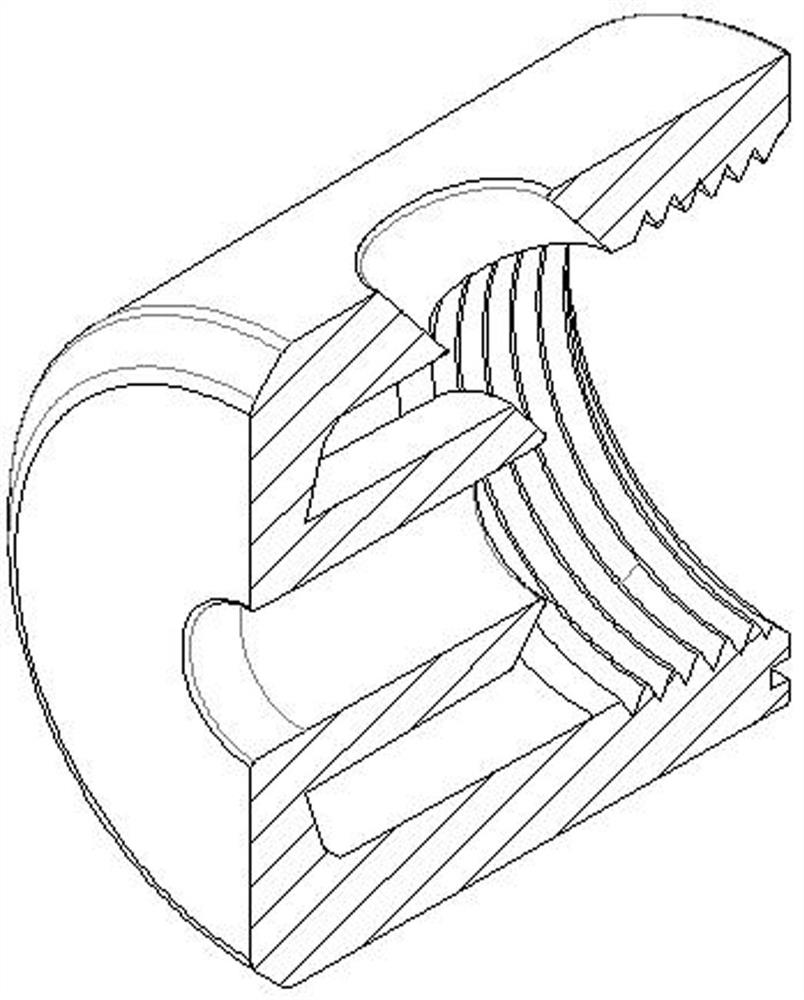

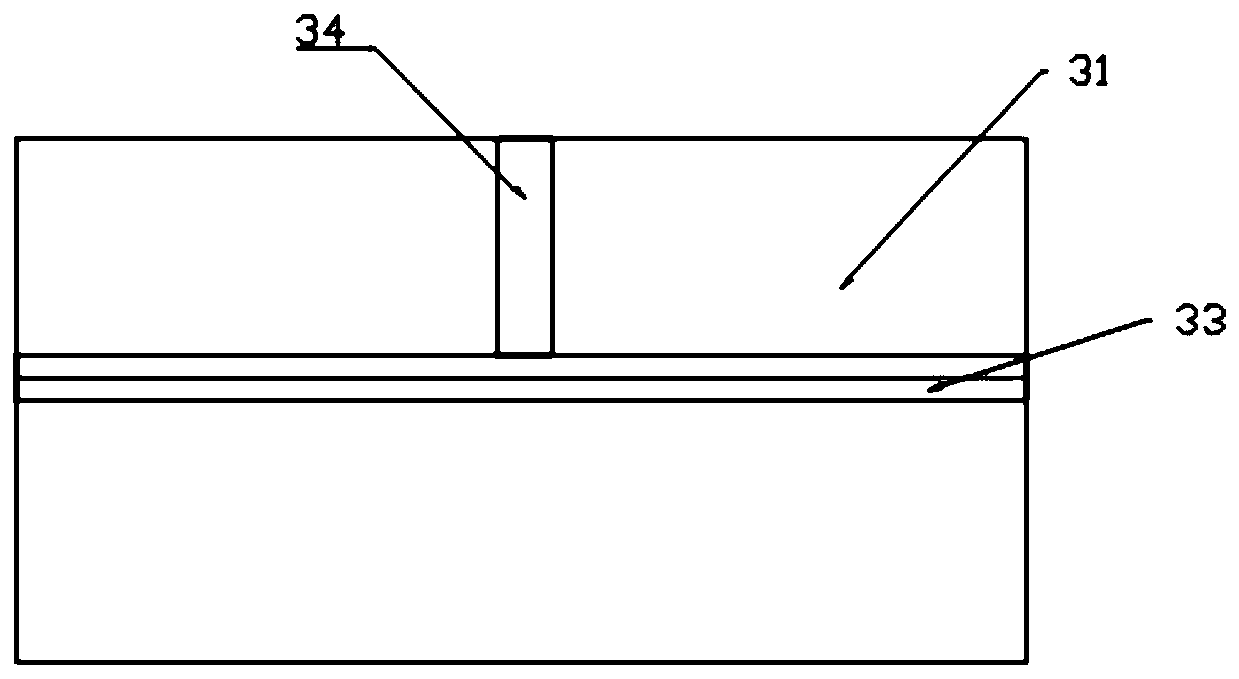

Oil distribution disc and cylinder block assembly of hydraulic pump and machining method thereof

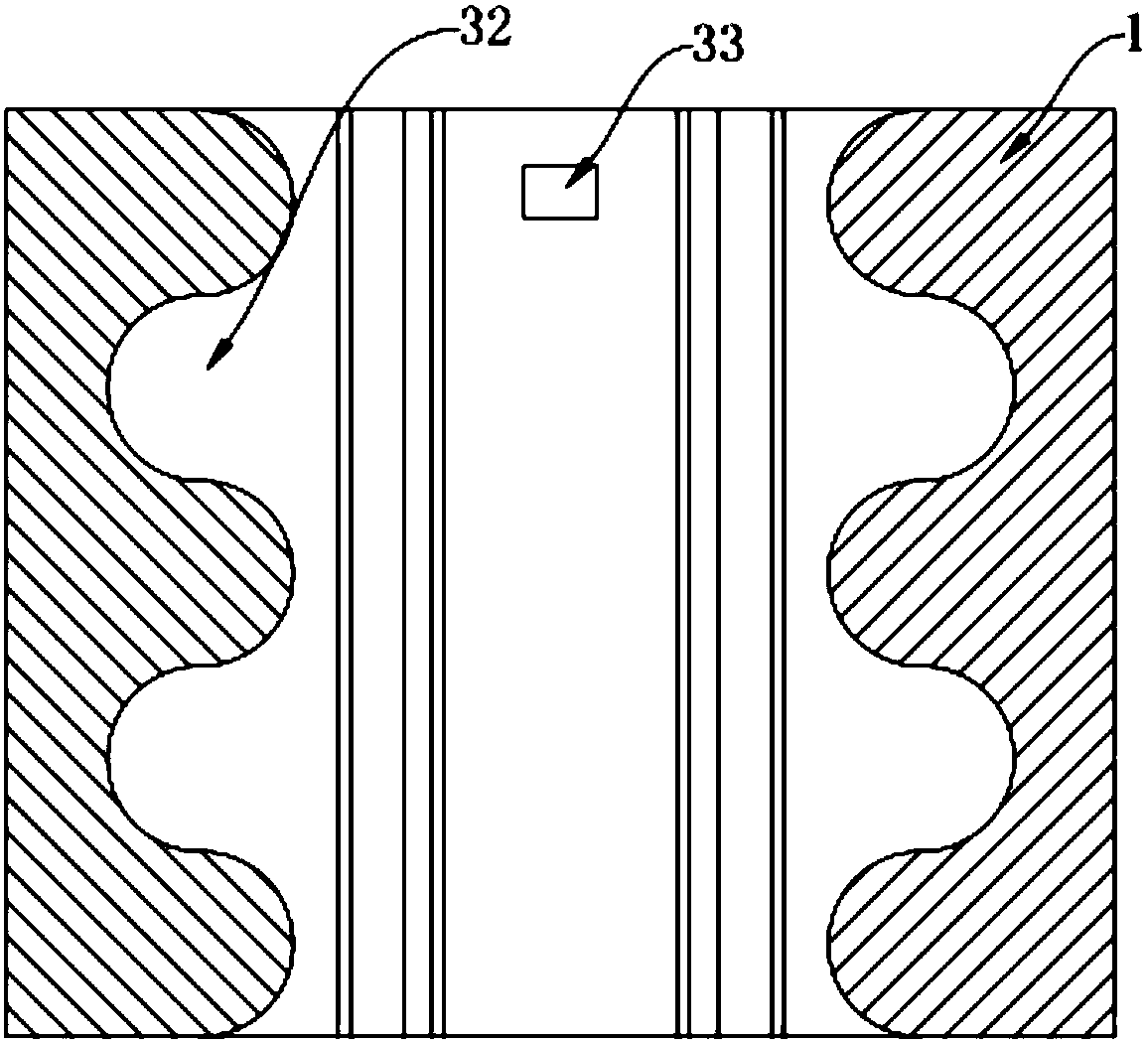

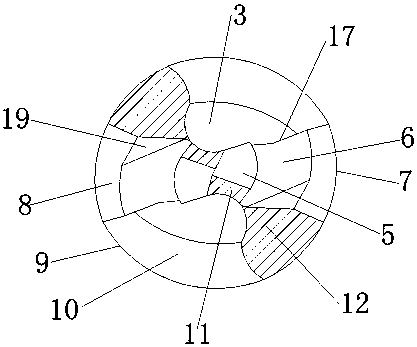

InactiveCN104514710AFit tightlyAchieve circumferential limitPositive displacement pump componentsLiquid fuel engine componentsBodies oilHydraulic pump

The invention discloses an oil distribution disc and cylinder body assembly of a hydraulic pump. The oil distribution disc and cylinder body assembly includes a cylinder body and an oil distribution disc, wherein the cylinder body is sintered on a main body workblank by welding copper, and an internal transmission spline is arranged at the center of the cylinder body; the cylinder body is matched with the oil distribution disc by spherical surfaces, for improving work efficiency of the oil distribution disc; meanwhile, a cylinder body rotating cavity is arranged in the cylinder body, a spring is installed in the cylinder body rotating cavity, thus being beneficial to form fitting of the cylinder body and the oil distribution disc; a plunger oil pressing cavity is arranged at the periphery of the cylinder body rotating cavity, a cylinder sleeve is installed in the plunger oil pressing cavity in a pressing manner, and a plunger is installed in the hole of the cylinder sleeve; the oil distribution disc is cooperatively installed on the valve body of the hydraulic pump, and an inner circle tool relief groove is arranged on the oil distribution disc; in addition, the oil distribution plate is provided with a first kidney-shaped oil sucking and pressing hole and a second kidney-shaped oil sucking and pressing hole, a vibration damping groove is arranged on the side of each of the first and second kidney-shaped oil sucking and pressing holes, for cooperatively sucking and pressing oil, and reducing vibration; the plunger oil pressing cavity is communicated with the first and second kidney-shaped oil sucking and pressing holes by cylinder body oil paths.

Owner:HUNAN AGRICULTURAL UNIV

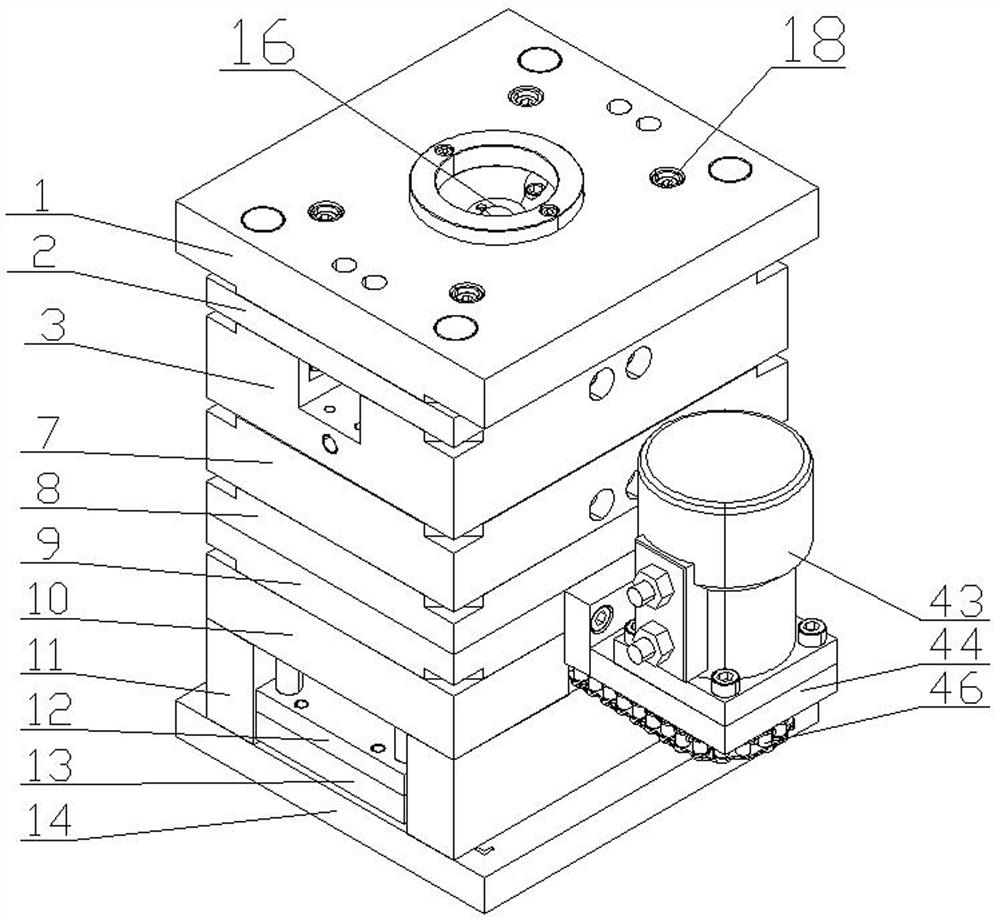

Mold for machining internal thread of plastic part and pulling core

The invention discloses a mold for machining an internal thread of a plastic part and pulling a core. The mold comprises a fixed mold body, a movable mold body and an oil cylinder motor, a first motorgear is fixed to an output shaft of the oil cylinder motor, a transmission mechanism is arranged in the movable mold body and comprises a rotating shaft, a first insert gear and n second insert gears, the first insert gear is fixed to one end of the rotating shaft, a second motor gear is fixed to the other end of the rotating shaft, an anti-strain mechanism is further arranged in the movable moldbody and comprises n anti-rotation inserts, a hole site insert is arranged in each anti-rotation insert, one end of each hole site insert is fixed to the corresponding second insert gear, a thread insert is fixed to the other end of each hole site insert, the thread inserts penetrate through a mold core to be movably arranged in a mold cavity to be used for shaping the plastic part with the internal thread, and the rotating shaft is driven by driving force provided by the oil cylinder motor to rotate so as to drive the thread inserts to rotate. The mold has the advantages that strain and burn-out cannot be caused, and the generation of burrs of the mold is avoided; and a thread head and a thread tail of the thread are located at the unified position through a core-in limiting mechanism.

Owner:海宁鐵三角科技有限公司

Automatic pipe breaking device for vertical heat collecting pipe production line

PendingCN112045747AAutomate truncationIncrease productivityNon-rotating vibration suppressionMetal working apparatusEngineeringCam

The invention belongs to the related technical field of heat collecting pipe production, and discloses an automatic pipe breaking device for a vertical heat collecting pipe production line. The automatic pipe breaking device comprises a body, a linear bearing, a spring, a double-roller mechanism, a double-cam mechanism, an auxiliary shaft, a main shaft, a rolling linear guide sleeve pair and a cutter; a containing hole is formed in one end of the body, a sliding bearing block is arranged at the other end of the body, and two supporting blocks are arranged in the middle of the body at intervals; the linear bearing is arranged in the containing hole; the rolling linear guide sleeve pair is arranged on the sliding bearing block; one end of the main shaft penetrates through the linear bearing,and the other end penetrates through the sliding bearing block and then is connected to the cutter; the double-roller mechanism is fixedly connected to the main shaft, the spring is arranged on the mains shaft in a sleeving mode, and the spring is located between the linear bearing and the double-roller mechanism; and the two ends of the auxiliary shaft are arranged on the two supporting blocks respectively, the double-cam mechanism is arranged on the auxiliary shaft, and two cams of the double-cam mechanism are separately connected with two rollers of the double-roller mechanism respectively. According to the automatic pipe breaking device, automation is achieved, and the structure is simple.

Owner:HUAZHONG UNIV OF SCI & TECH +1

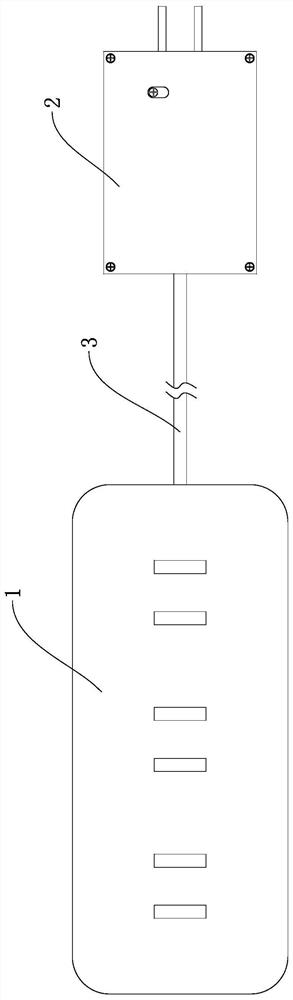

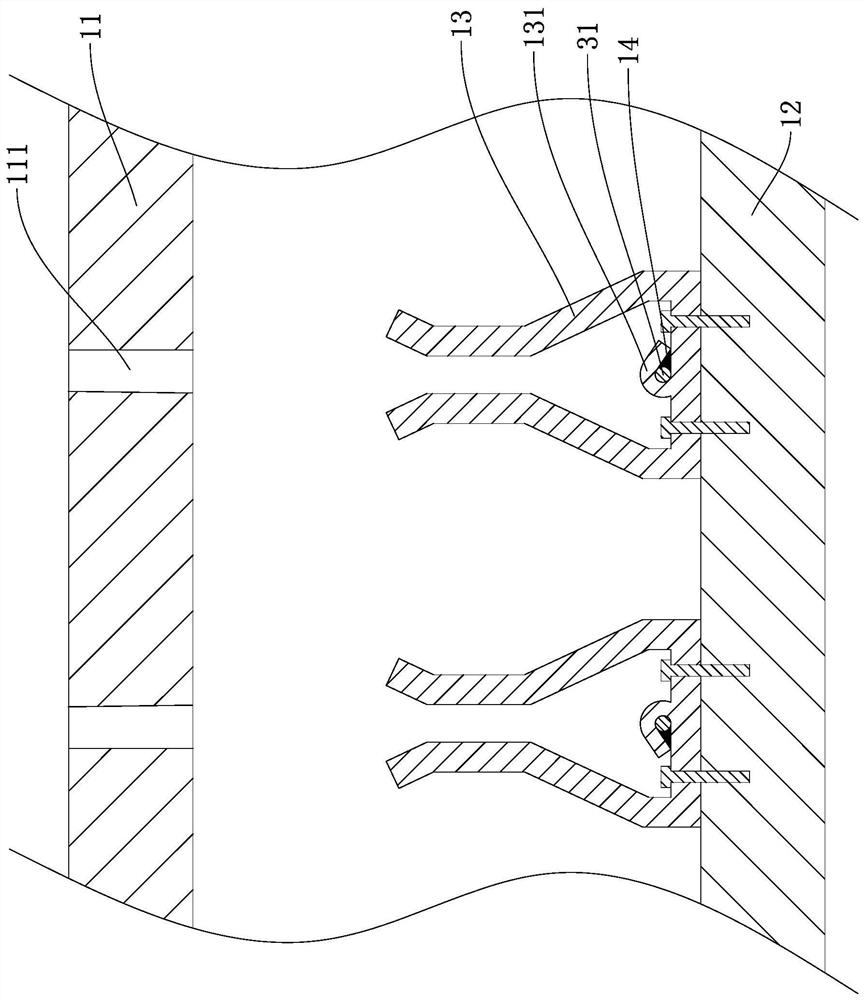

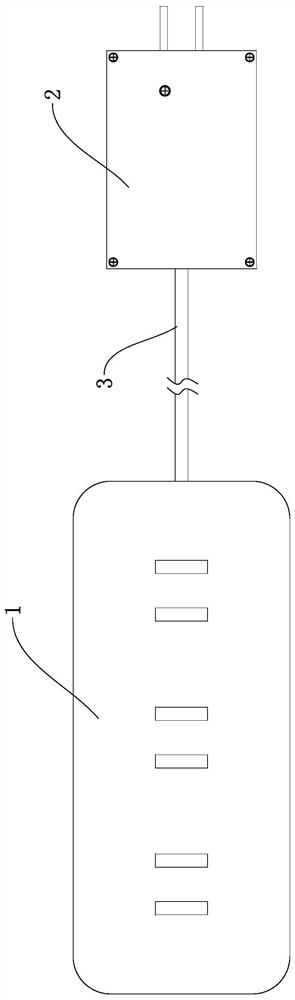

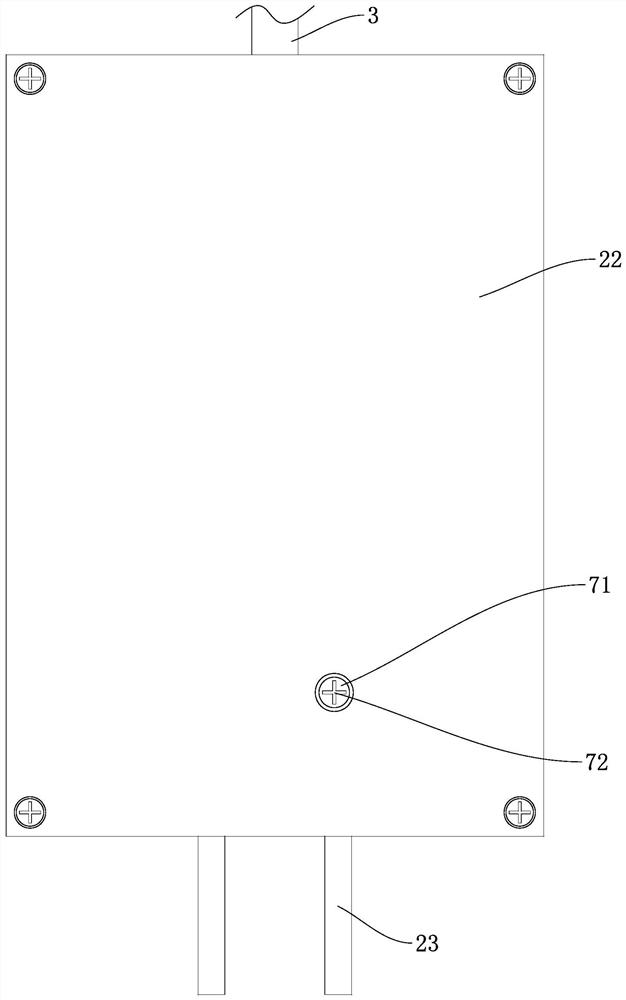

Intelligent patch board having high reliability of connection between power line and conductive socket

InactiveCN111817060AFirmly connectedAchieve circumferential limitCoupling device detailsElectrical connectionEngineering

The invention discloses an intelligent patch board having high reliability of connection between a power line and a conductive socket. The intelligent patch board comprises an extension socket body and a plug body, wherein the extension socket body is electrically connected with the plug body through the power line, the extension socket body comprises a shell and a bottom plate fixed at an openingin a lower end of the shell, a plurality of pairs of conductive sockets are fixed on the bottom plate, each pair of conductive sockets is electrically connected with the power line, a jack through which a conducting strip on a power plug in the electric appliance passes is formed in the shell above each conductive socket, a conductive pressing piece is integrally formed at the inner bottom of each conductive socket, a wire core in the power line is pressed on the inner bottom of each conductive socket after the conductive pressing piece is bent, and soldering tin is filled in a gap formed bythe conductive sockets, the conductive pressing pieces and the wire core. The intelligent patch board is advantaged in that the fixing strength of the wire core and the conductive socket can be improved, and the conductive effect of the conductive socket and the wire core can further be improved, i.e., reliability and the service life of the patch board can be effectively improved.

Owner:沈一群

Digital fitness chair

InactiveCN103285555AEasy to installEasy to install inFrictional force resistorsMovement coordination devicesEngineeringPotentiometer

The invention discloses a digital fitness chair. Handle mechanisms are arranged on the two sides of a chair body respectively, two pedal mechanisms are arranged on the front lower side of the chair body, first connecting rods in the handle mechanisms are in the shape of N, one ends of the first connecting rods are connected with handles, mounting sleeves are arranged at the other ends of the first connecting rods, the mounting sleeves are movably sleeved and combined on mounting seats, first potentiometers are arranged at one ends of the mounting seats, the rotating shafts of the first potentiometers and the mounting sleeves are circumferentially limited, the other ends of the mounting seats are hinged to supports, second potentiometers are arranged on the supports, the rotating shafts of the second potentiometers are arranged in the hinge holes of the other ends of the mounting seats, the rotating shafts of the second potentiometers and the mounting seats are circumferentially limited, and supporting rods in each pedal mechanism are composed of a first supporting rod and a second supporting rod, one ends of the first supporting rods and one ends of the second supporting rods are hinged and can be locked, and the other ends of the first supporting rod and the other ends of the second supporting rods are fixed with a cylinder barrel and the bottom portion of the chair body respectively. The digital fitness chair is simple in structure, the rotating angle of the handles is large, and the height of pedals can be adjusted.

Owner:于明强

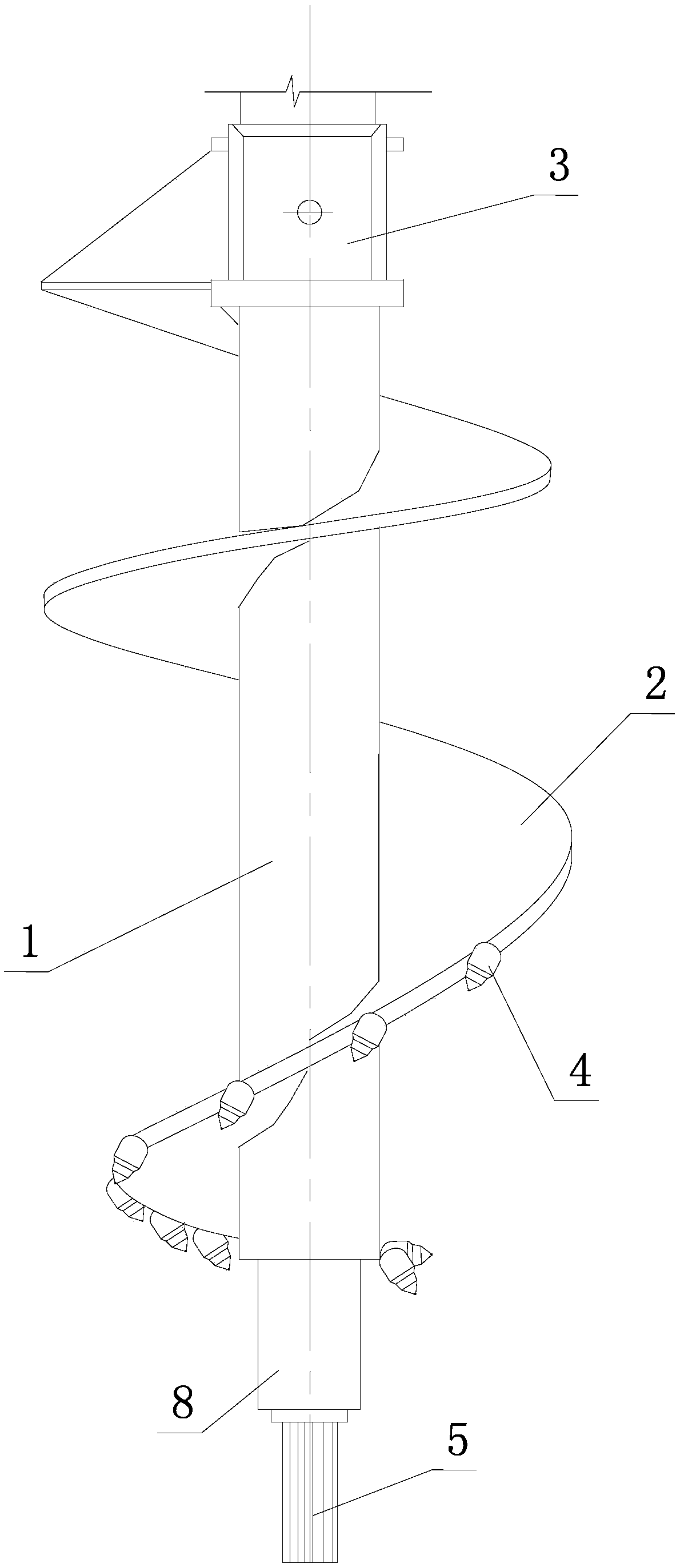

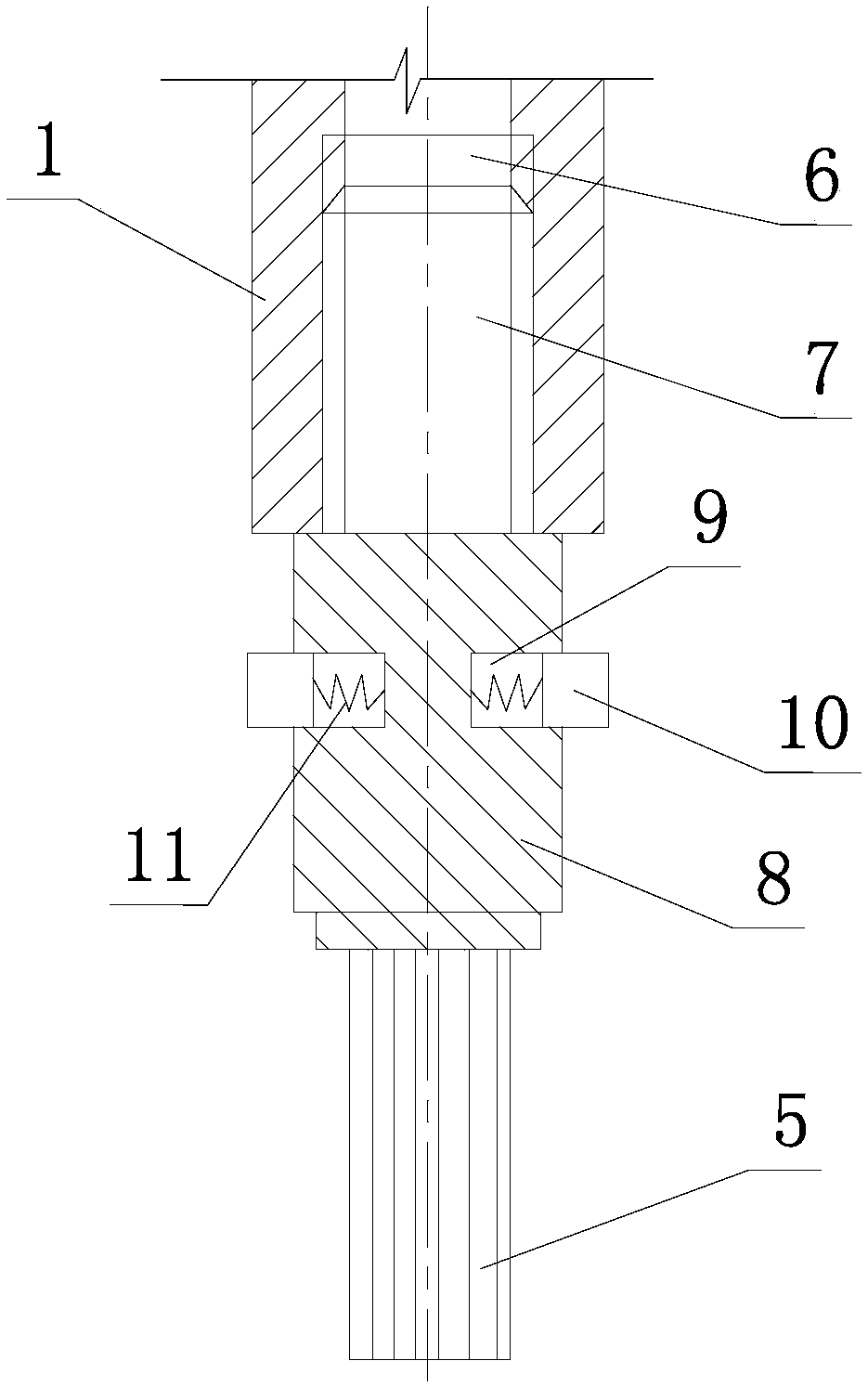

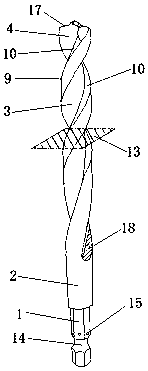

Drill bit for breaking waste pipe pile, and method for breaking waste pipe pile and pouring new pile

The invention discloses a drill bit for breaking a waste pipe pile, and a method for breaking the waste pipe pile and pouring a new pile. The drill bit comprises a core shaft, spiral blades are arranged at the external circumference of the core shaft, and a connecting part in butt joint with a drill pipe of a drill jig is arranged at the top of the core shaft. A plurality of cutting teeth are formed at least below the middle of the spiral blades, a vertical steel bar bundle formed by a plurality of short steel bars in a welded mode is arranged at the bottom of the core shaft, the steel bar bundle is coaxial with the core shaft, and the outer diameter of the steel bar bundle is less than or equal to the inner diameter of the to-be-crushed waste pipe pile. The key of the method is that the two steps of waste pile crushing and new pile hole forming are integrated and conducted synchronously. According to the drill bit and the method, the waste pipe pile with the depth exceeding 20 meterscan be effectively broken, and waste pile breaking and new pile hole forming can be conducted synchronously, so that the construction efficiency is improved, and the construction cost is lowered.

Owner:中地君豪高科股份有限公司

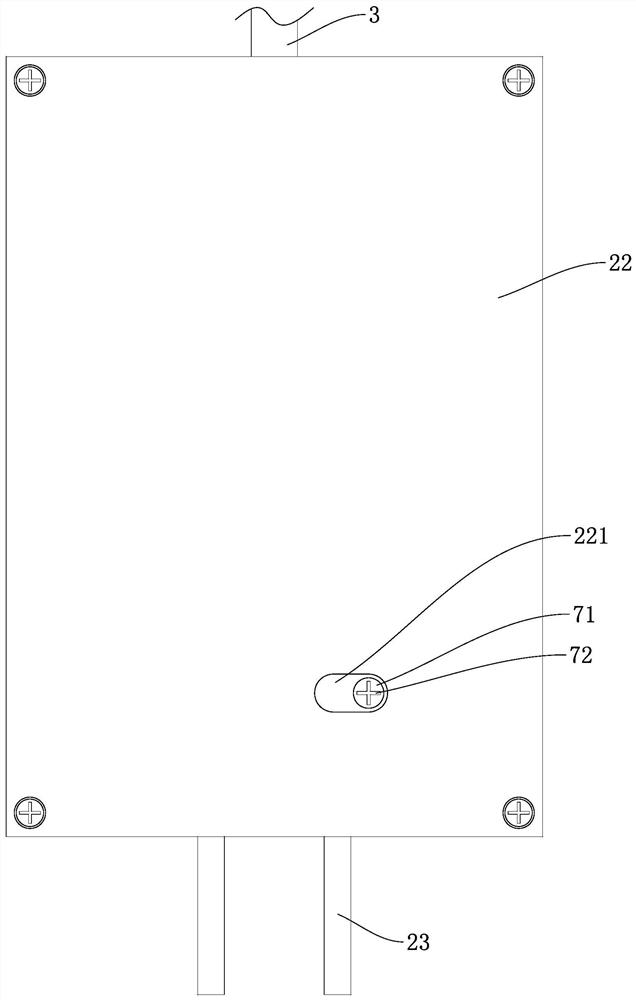

Intelligent patch board with anti-loosening function

InactiveCN111786160AWith anti-loosening functionSmooth rotationCoupling contact membersElectrical connectionStructural engineering

The invention discloses an intelligent patch board with an anti-loosening function, which comprises an extension socket body and a plug body, wherein the extension socket body is electrically connected with the plug body through a power line; the extension socket body comprises a shell and a bottom plate fixed at an opening at the lower end of the shell, conductive sockets are fixed on the bottomplate, the conductive sockets are electrically connected with a power line, and jacks for conductive sheets on a plug in a power utilization device to pass through are arranged in the shell positionedabove each conductive socket; each conductive socket is provided with a U-shaped spring clamp, the spring clamp is used for inwards extruding two conductive elastic sheets on the conductive socket, and the outer wall of each conductive elastic sheet in each conductive socket is provided with an embedding groove for embedding the side edge of the spring clamp. The reliability of the contact between the conductive sheet on the plug in the electric appliance and the conductive elastic sheet on the conductive socket can be improved, so that the phenomenon of poor contact between the plug in the electric appliance and the extension socket can be avoided.

Owner:沈一群

Body building chair

ActiveCN103263754BEasy to installEasy to useMovement coordination devicesCardiovascular exercising devicesArchitectural engineeringPotentiometer

The invention discloses a body building chair. Two sides of a chair main body are respectively provided with a handle mechanism, two pedal mechanisms are arranged at the lower-front side of the chair main body, a first connecting rod in each handle mechanism is L-shaped, one ends of each first connecting rods are connected with handles, the other ends of the first connecting rods are hinged with an installing base, a first potentiometer is arranged on the installing base, a rotating shaft of the first potentiometer is circumferentially limited in a hinge hole in the other end of each first connecting rod, the installing base is hinged with a bracket, a second potentiometer is arranged on the bracket, a rotating shaft of the second potentiometer is circumferentially limited in a hinge hole of the installing base, support rods in each pedal mechanism comprise a first support rod and a second support rod, one ends of which are hinged and can be locked and the other ends are respectively fixed with a cylinder and the bottom of the chair main body. The body building chair is simple in structure, larger in angle for which the handles can be oscillated, and capable of regulating the height of pedals.

Owner:南通江海港建设工程有限公司

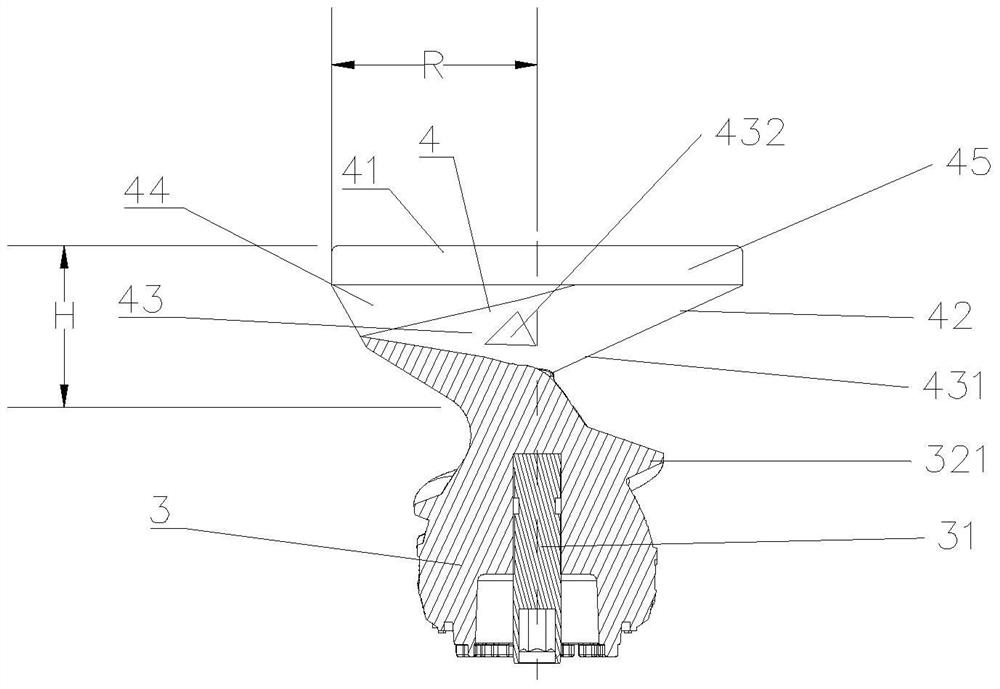

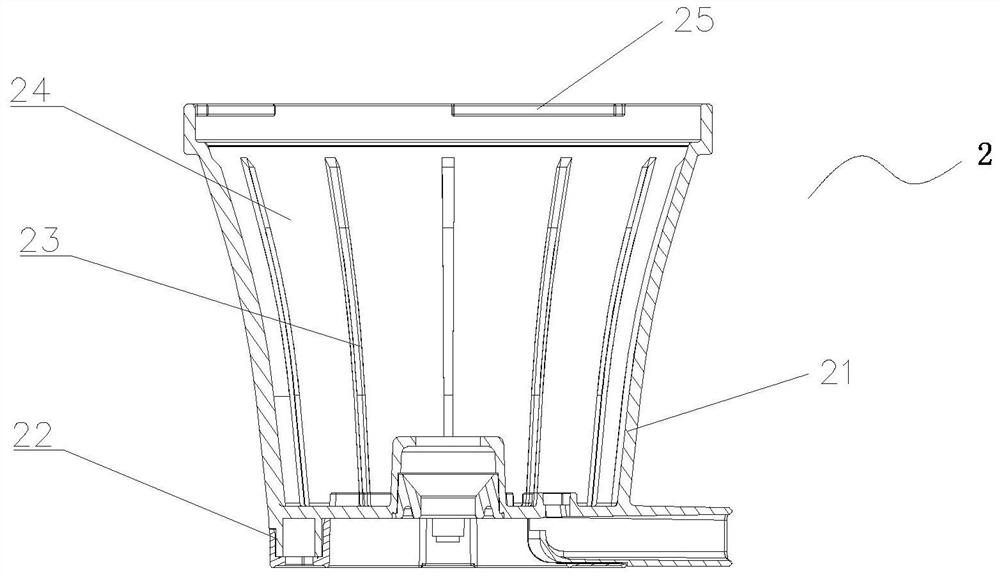

Juicer with reliable structure

The invention provides a juicer with a reliable structure. The juicer comprises a machine base, a juice collection container connected to the machine base, an extrusion screw rod longitudinally disposed in the juice collection container, and an upper cover which covers an upper port of the juice collection container, wherein an opening and a feeding channel communicating with the opening are formed in the upper cover; a rotary feeding device is disposed on the upper end of the extrusion screw rod; the rotary feeding device and the extrusion screw rod form an integral manner; the extrusion screw rod drives the rotary feeding device to move; the rotary feeding device comprises a feeding hole and a discharge hole; the feeding hole and the opening are disposed correspondingly; a circumferential limiting structure is disposed on the upper cover; a positioning structure is disposed circumferentially on the rotary feeding device; and the circumferential limiting structure is coordinated withthe positioning structure to conduct circumferential limiting of the extrusion screw rod. Through coordination of the limiting structure and the positioning structure, assembly accuracy of the rotaryfeeding device, the extrusion screw rod and the juice collection container can be further increased; and reliability of transmission can be ensured.

Owner:JOYOUNG CO LTD

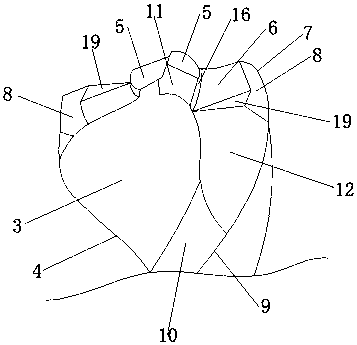

Quick change chip removing drill bit

The invention provides a quick change chip removing drill bit. The quick change chip removing drill bit comprises a drill handle and a cutter body coaxial with the drill handle. A spiral groove is formed in the cutter body, a drill point is arranged at the top end of the cutter body, and two rear cutter faces in central symmetry are arranged on the drill point. Each rear cutter face comprises a stepped first cutter face, a stepped second cutter face, and a third cutter face formed by coping towards the second cutter face along a back ridge of a drill bit, a spiral chip guide cambered face is arranged in the spiral groove along a tail ridge of the drill bit, rear ditch ridges of the first cutter face, the second cutter face and the third cutter face and the tail ridge of the top of the cutter body are simultaneously coped in the chisel edge direction, a first coping face and a second coping face are formed on the front face of the cutter body, an annular groove is formed in the drill handle along the outer peripheral face, and multiple hemispherical blind holes are formed in the drill handle.

Owner:JIANGSU TIANGONG PRECISION TOOLS CO LTD

Digital fitness chair

InactiveCN103285555BEasy to installEasy to useFrictional force resistorsMovement coordination devicesEngineeringPotentiometer

The invention discloses a digital fitness chair. Handle mechanisms are arranged on the two sides of a chair body respectively, two pedal mechanisms are arranged on the front lower side of the chair body, first connecting rods in the handle mechanisms are in the shape of N, one ends of the first connecting rods are connected with handles, mounting sleeves are arranged at the other ends of the first connecting rods, the mounting sleeves are movably sleeved and combined on mounting seats, first potentiometers are arranged at one ends of the mounting seats, the rotating shafts of the first potentiometers and the mounting sleeves are circumferentially limited, the other ends of the mounting seats are hinged to supports, second potentiometers are arranged on the supports, the rotating shafts of the second potentiometers are arranged in the hinge holes of the other ends of the mounting seats, the rotating shafts of the second potentiometers and the mounting seats are circumferentially limited, and supporting rods in each pedal mechanism are composed of a first supporting rod and a second supporting rod, one ends of the first supporting rods and one ends of the second supporting rods are hinged and can be locked, and the other ends of the first supporting rod and the other ends of the second supporting rods are fixed with a cylinder barrel and the bottom portion of the chair body respectively. The digital fitness chair is simple in structure, the rotating angle of the handles is large, and the height of pedals can be adjusted.

Owner:于明强

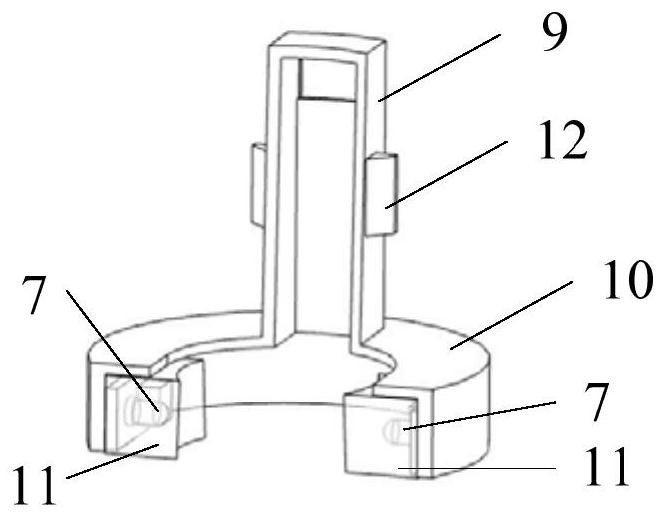

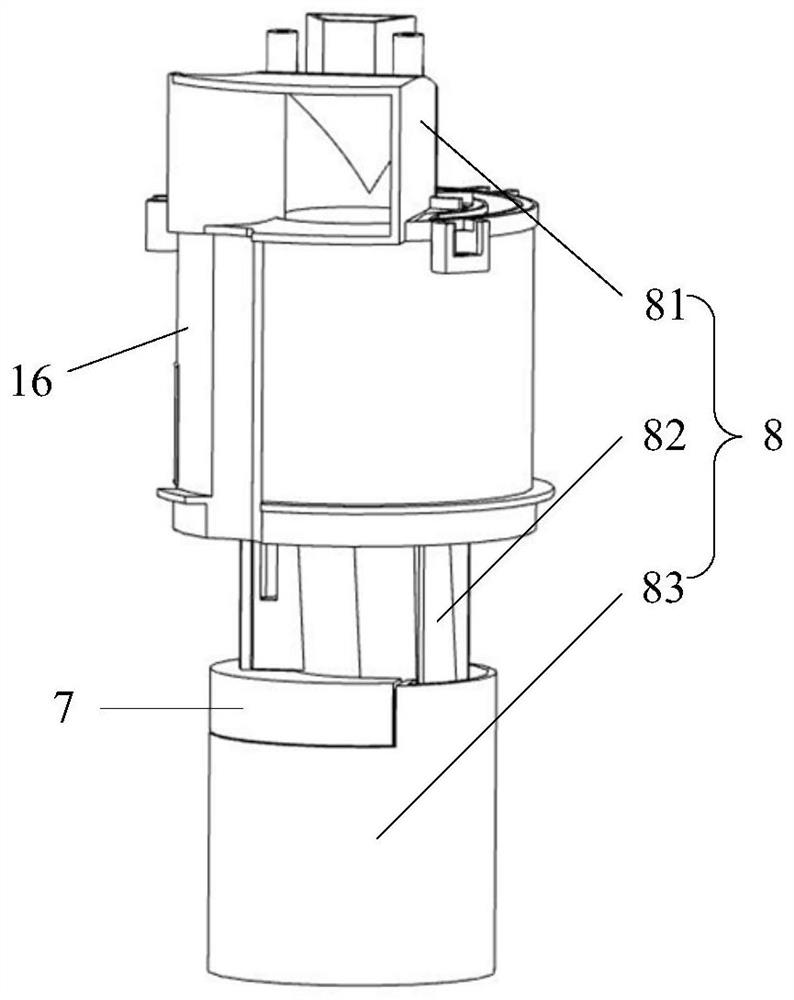

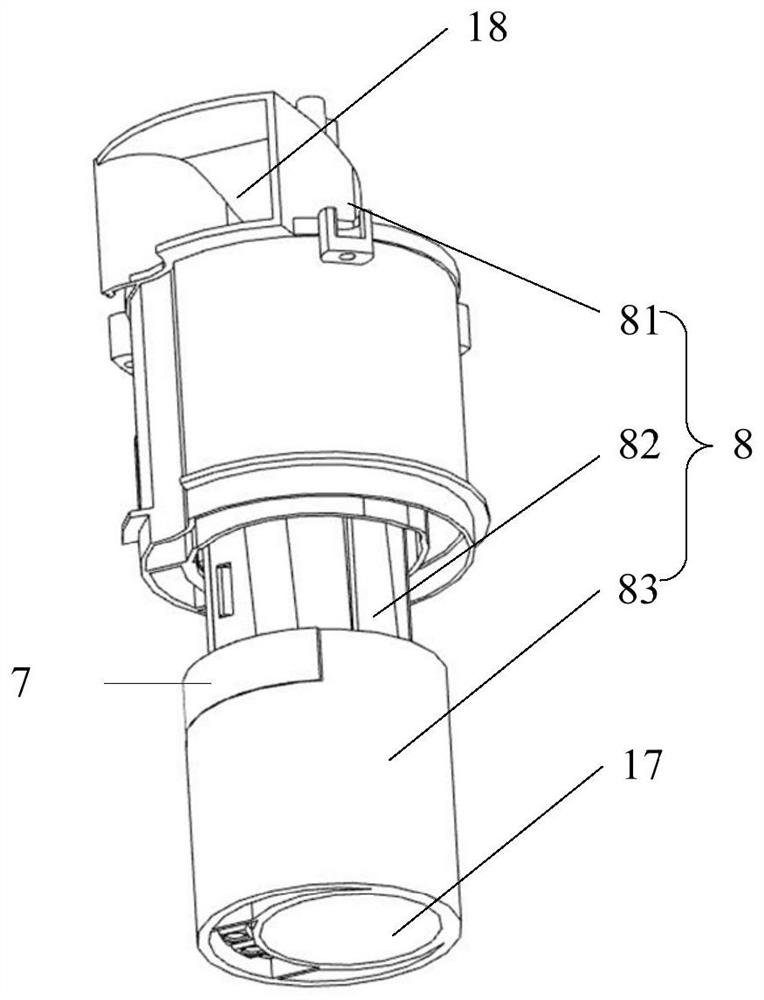

Assembling assembly and method of dust information acquisition assembly, dust collection cup and cleaning device

ActiveCN113545696AFirmly assembledImprove test accuracySuction filtersCleaning using toolsSurface cleaningEngineering

The invention discloses an assembling assembly and method of a dust information acquisition assembly, a dust collection cup and a cleaning device, belongs to the technical field of working surface cleaning, and solves the problem that in the prior art, the dust information acquisition assembly is clamped in an area between a fluid pipeline and a shell and shakes in a clamping area. The assembling assembly comprises the fluid pipeline and a support, the support is fixedly arranged on the side wall of the fluid pipeline, and the dust information acquisition assembly is fixedly arranged on the surface, facing the side wall of the fluid pipeline, of the support. The assembling method comprises the steps of fixing the dust information acquisition assembly to the surface, facing the side wall of the fluid pipeline, of the support; and along the radial direction of the fluid pipeline, moving the support towards the direction close to the fluid pipeline, so that the support is assembled on the fluid pipeline. The assembling assembly and method of the dust information acquisition component, the dust collection cup and the cleaning device can be used for cleaning the working surfaces.

Owner:PUPPY ELECTRONICS APPLIANCES INTERNET TECH (BEIJING) CO LTD

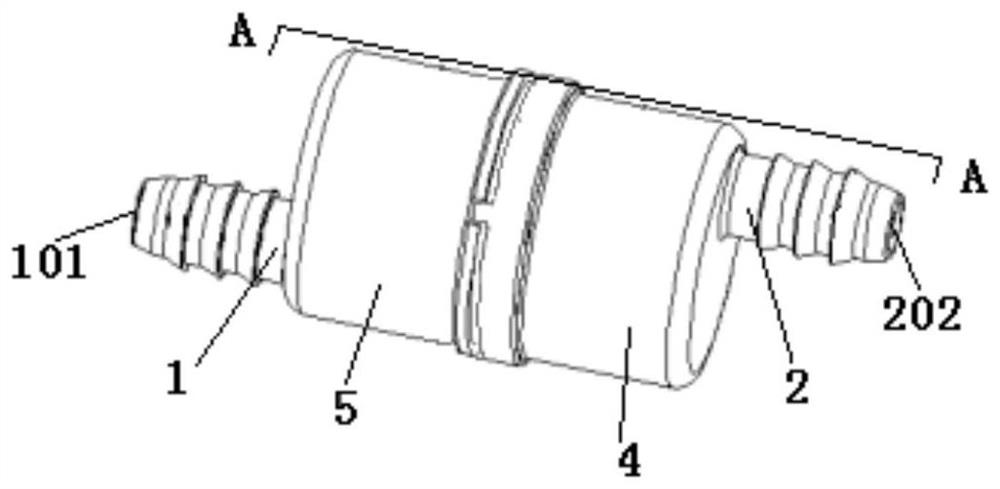

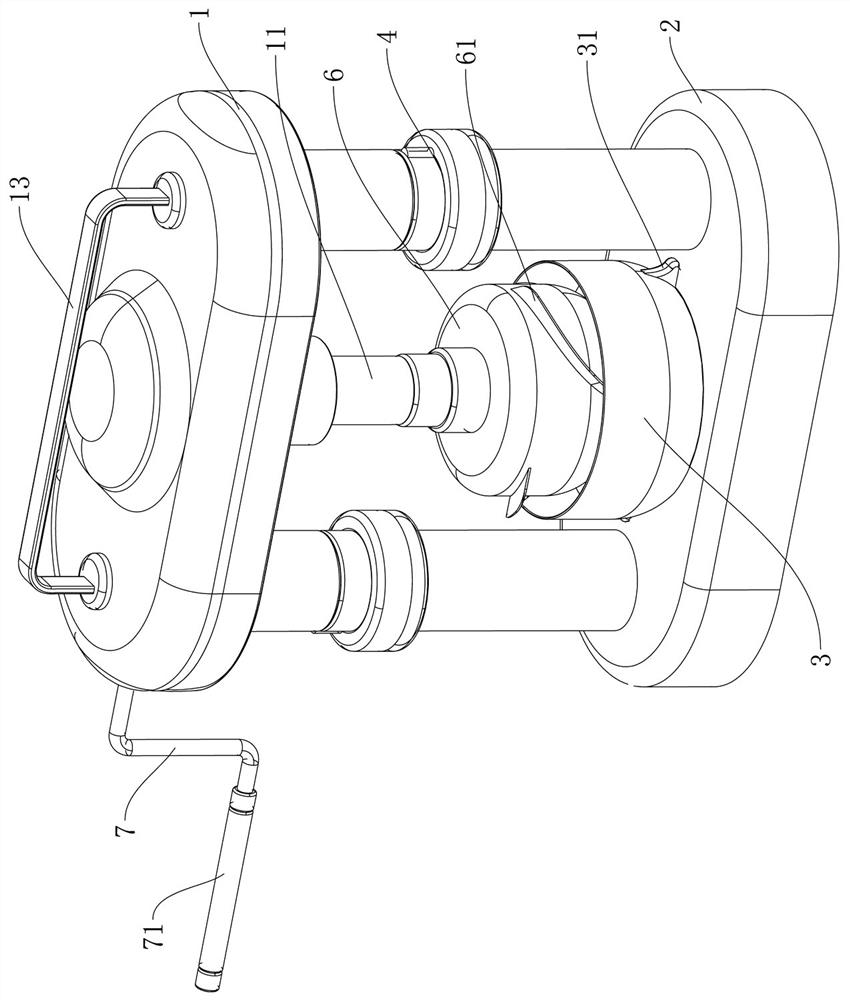

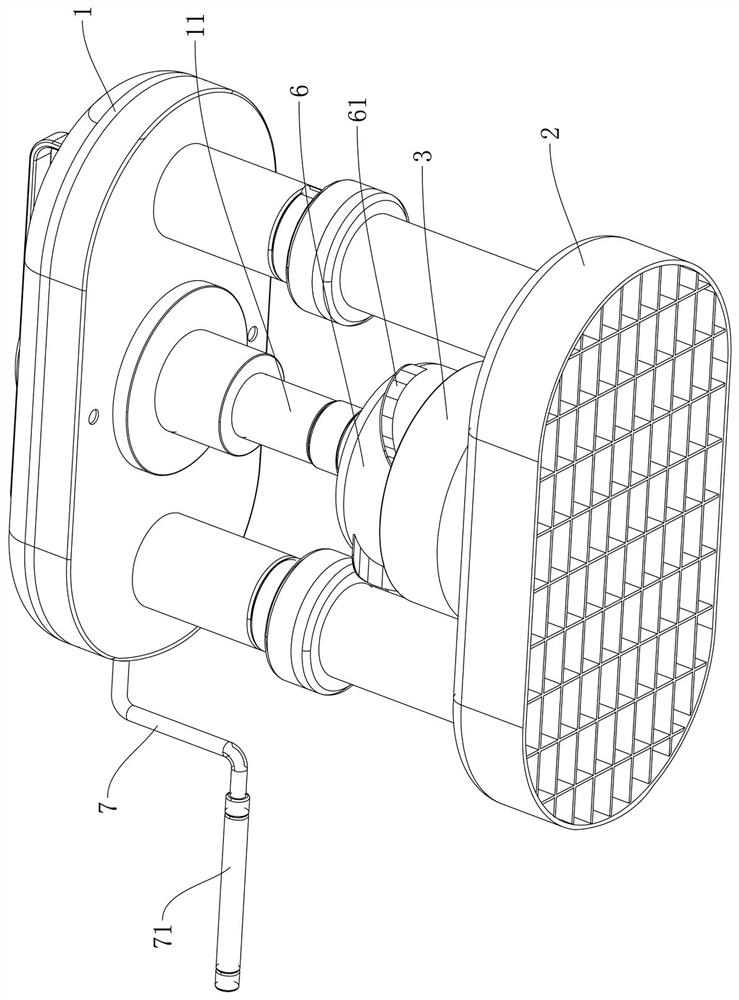

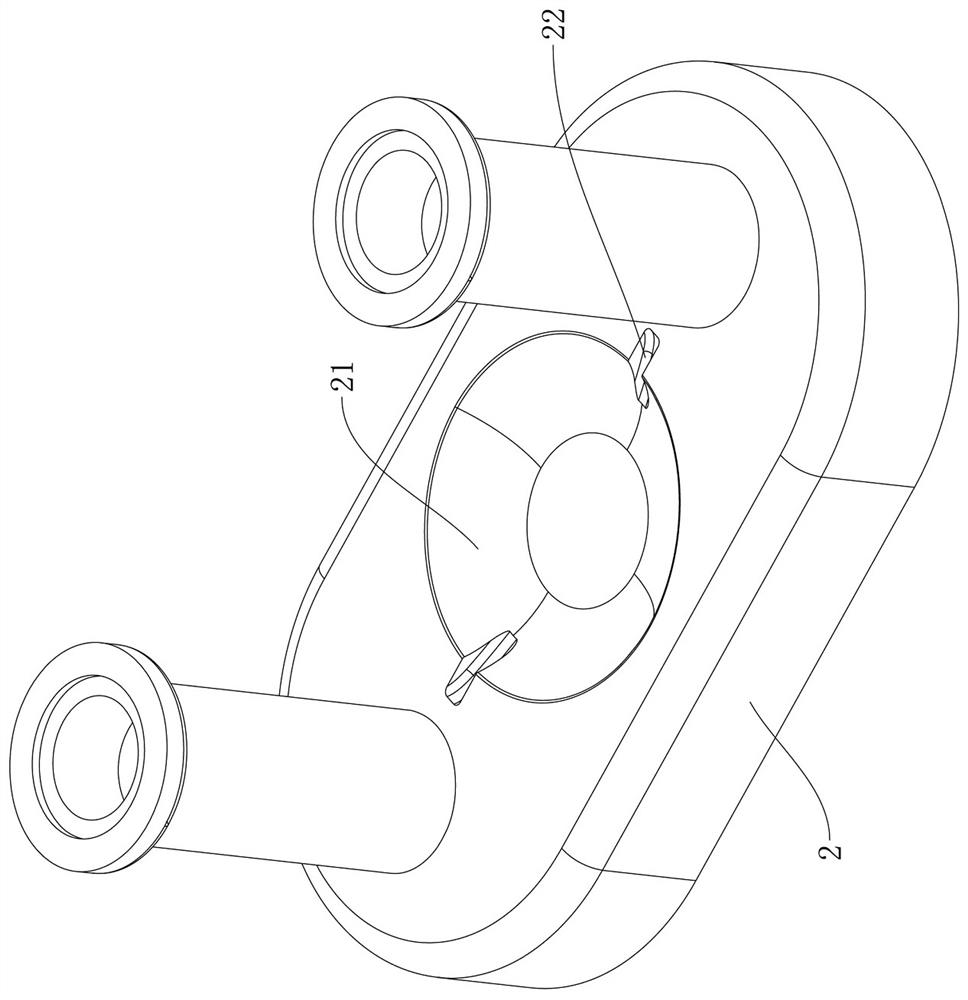

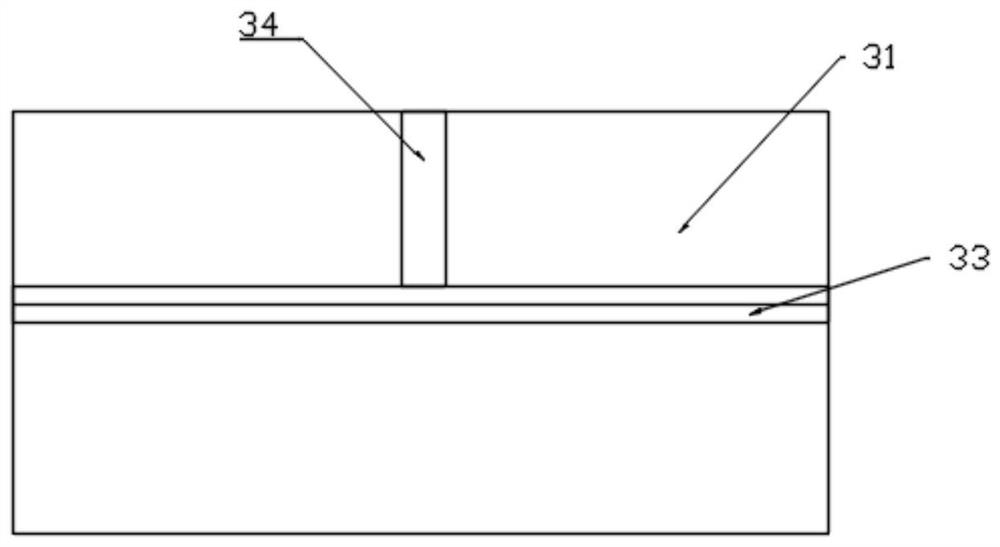

Noise reduction and vibration reduction device, brake vacuum pipeline and vehicle

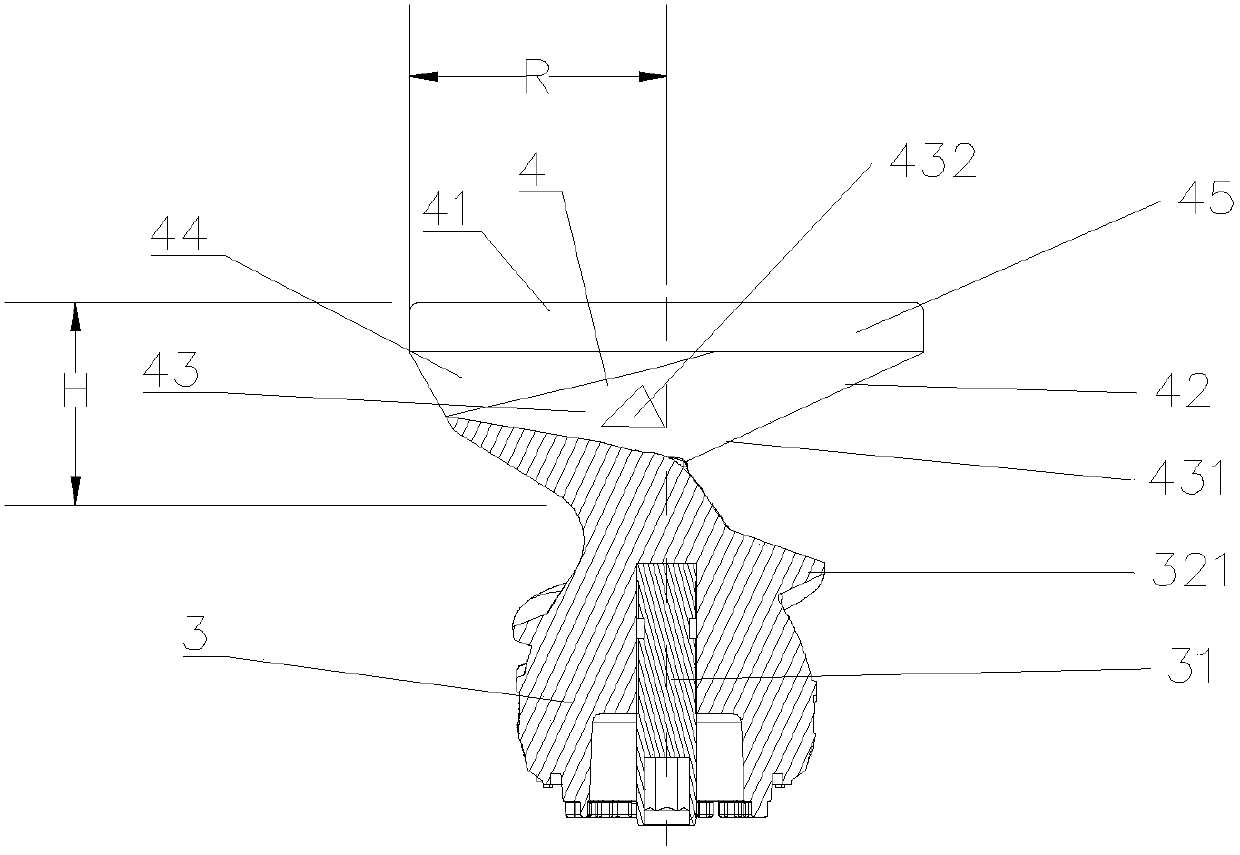

PendingCN113581154AReduce flow rateSolve abnormal vibrationPiping arrangementsResonant cavityEngineering

The invention relates to a noise reduction and vibration reduction device, a brake vacuum pipeline and a vehicle. The noise reduction and vibration reduction device comprises an air inlet pipe, a resonant cavity and an air outlet pipe, and the interior of the resonant cavity is divided into an air inlet cavity and an air outlet cavity through a partition plate; the air inlet pipe penetrates through the air outlet cavity and the partition plate to be communicated with the air inlet cavity, the air outlet pipe penetrates through the air inlet cavity and the partition plate to be communicated with the air outlet cavity, and air enters from the air inlet pipe, sequentially flows through the air inlet cavity, vent holes in the partition plate and the air outlet cavity and flows out from the air outlet pipe. At least two first radial protrusions are arranged on the inner side wall of the air inlet cavity, and at least two second radial protrusions are arranged on the inner side wall of the air outlet cavity, so that air flow in the small-area resonant cavity is counteracted reversely for multiple times, and noise reduction and vibration reduction are achieved. The invention further provides a brake vacuum pipeline which comprises the noise reduction and vibration reduction device. The invention further provides a vehicle which comprises the brake vacuum pipeline. The automobile brake vacuum pipeline solves the problem that a one-way valve generates vibration and abnormal sound due to the fact that the gas flow speed is continuously too high in an existing automobile brake vacuum pipeline.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

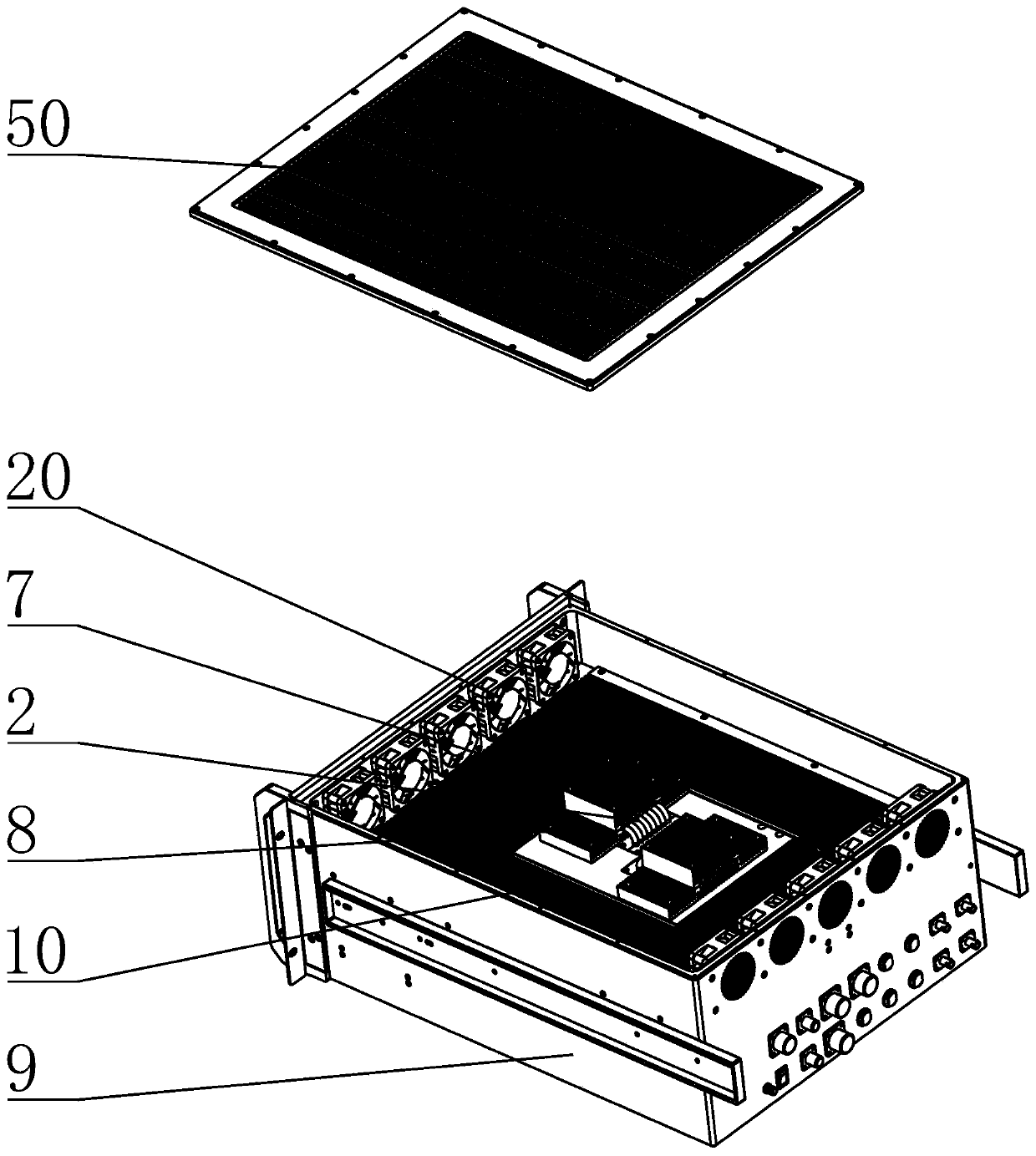

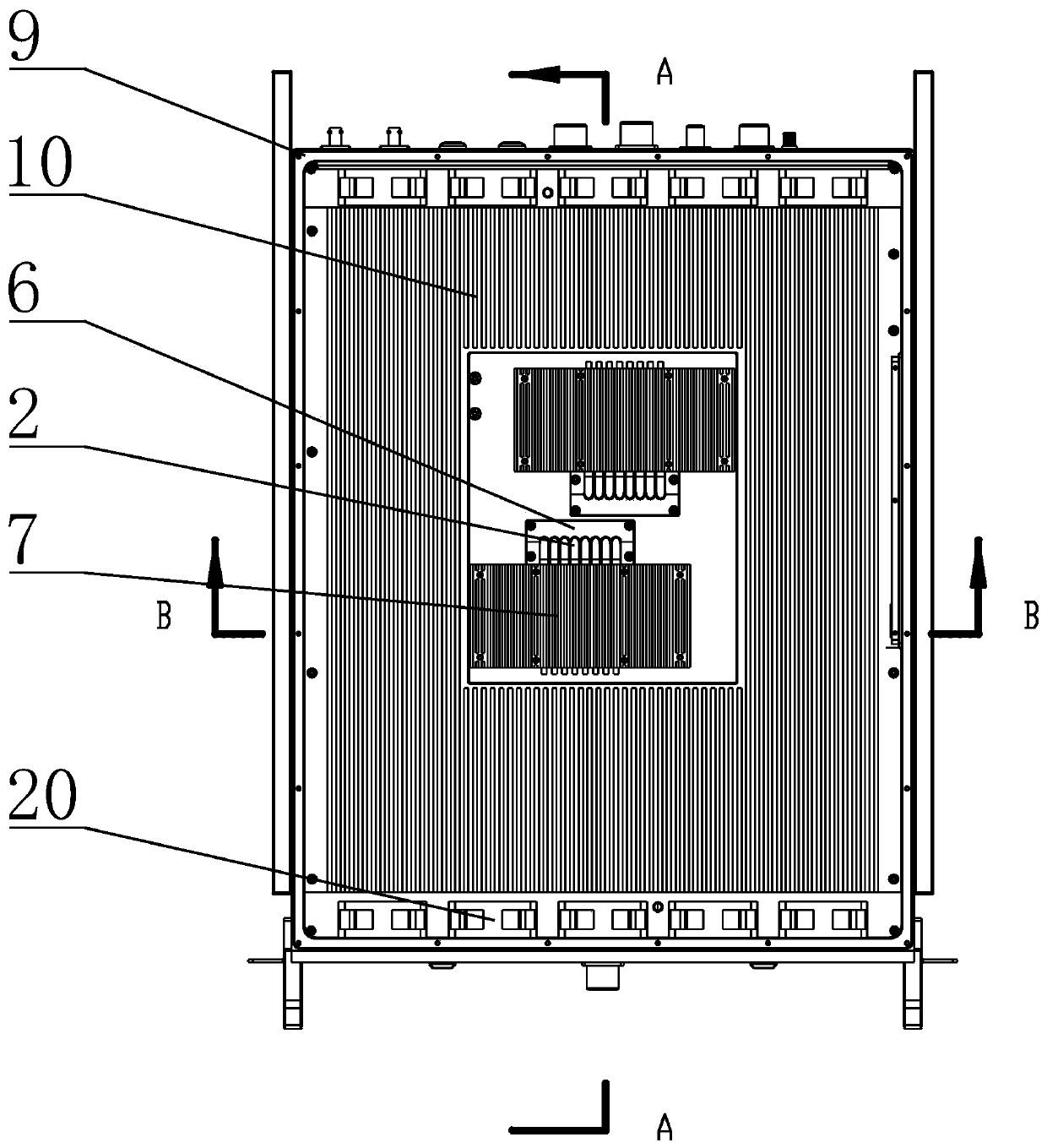

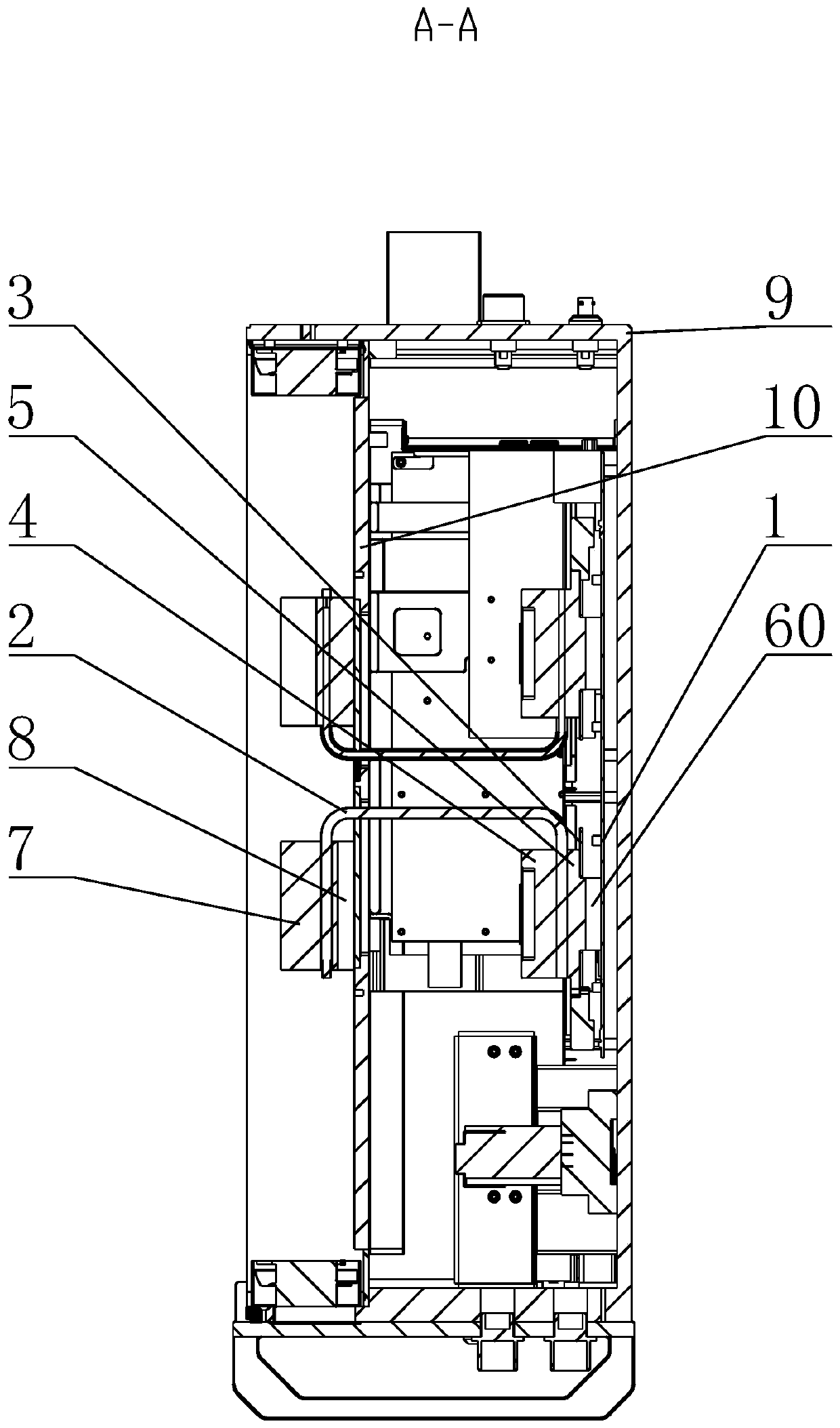

CPU heat dissipation installation structure for reinforced server

PendingCN110456895ARealize separate heat dissipationImprove cooling efficiencyDigital processing power distributionEnergy efficient computingCopperMotherboard

The invention provides a CPU heat dissipation mounting structure for a reinforced server. A mainboard is positioned at the bottom of a case of the reinforced server; a buckle is positioned at the periphery of the CPU on the mainboard; the heat conduction lower pressing block is positioned on the buckle and is in contact with the CPU to realize heat conduction; the heat conduction upper pressing block is positioned on the heat conduction lower pressing block, and the lower end connecting part of the heat dissipation copper pipe is clamped and positioned; the upper end connecting part of the heat dissipation copper pipe is positioned on the partition plate through a transition block; the heat dissipation lower pressing block is positioned on the partition plate; the heat dissipation upper pressing block is positioned on the heat dissipation lower pressing block, so that the upper end connecting part of the heat dissipation copper pipe is clamped and positioned; the partition plate divides a case of the reinforced server into an upper cavity structure and a lower cavity structure, and fan assemblies are further arranged in the upper cavity structure; and the fan assemblies are oppositely arranged on the two sides of the case correspondingly, so that heat dissipation of the heat dissipation upper pressing block and the heat dissipation lower pressing block is achieved through air channels formed by the fan assemblies, and the heat dissipation efficiency of the CPU is greatly improved.

Owner:合肥恒研智能科技有限公司

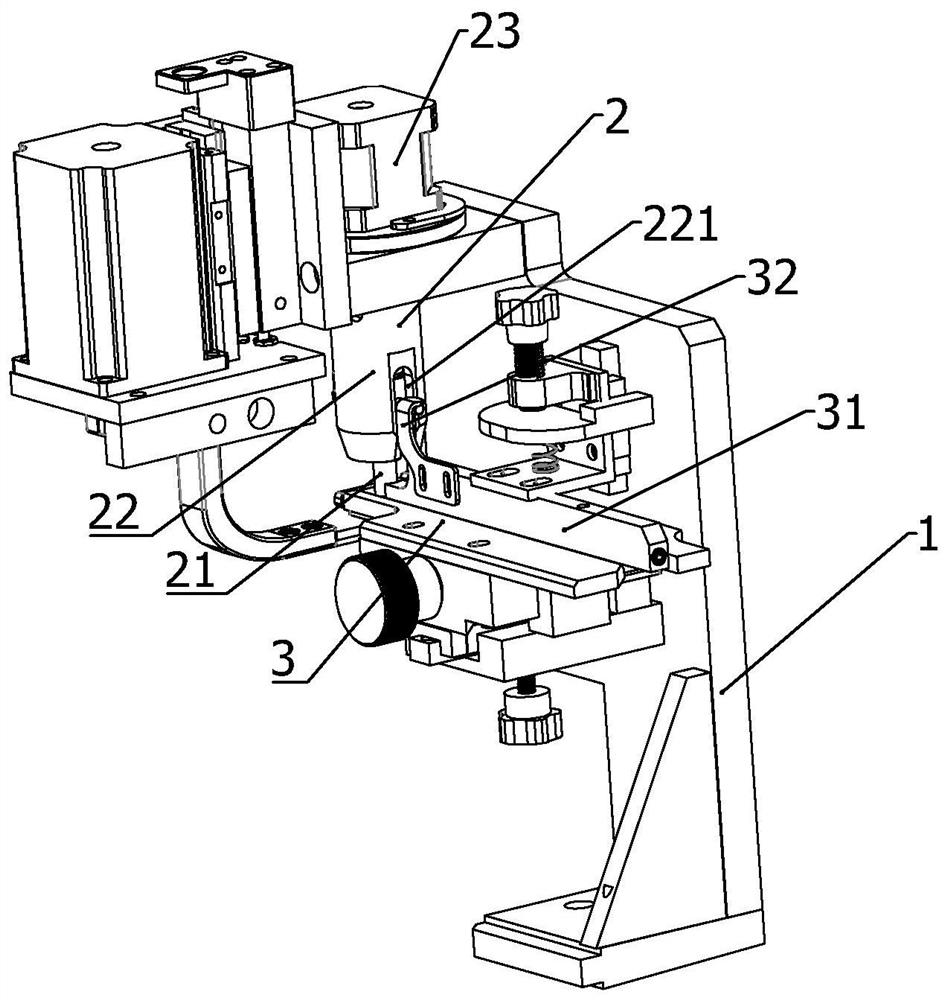

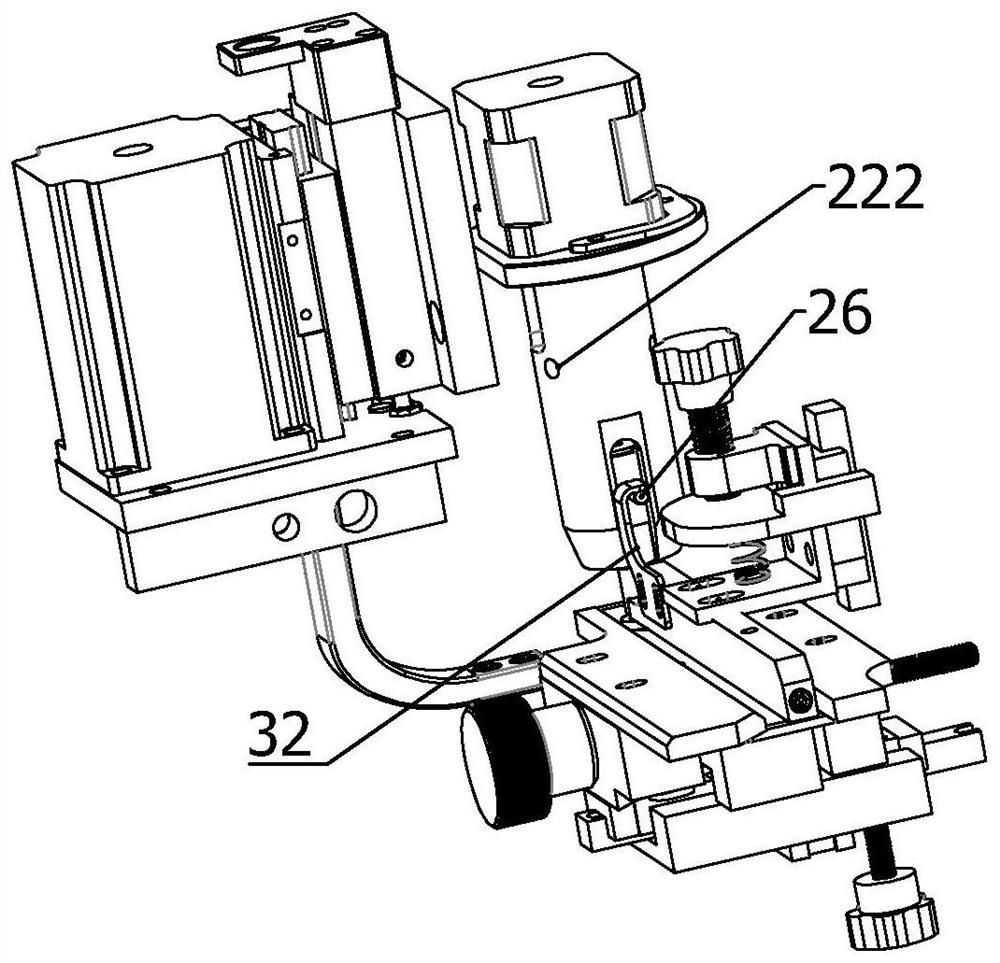

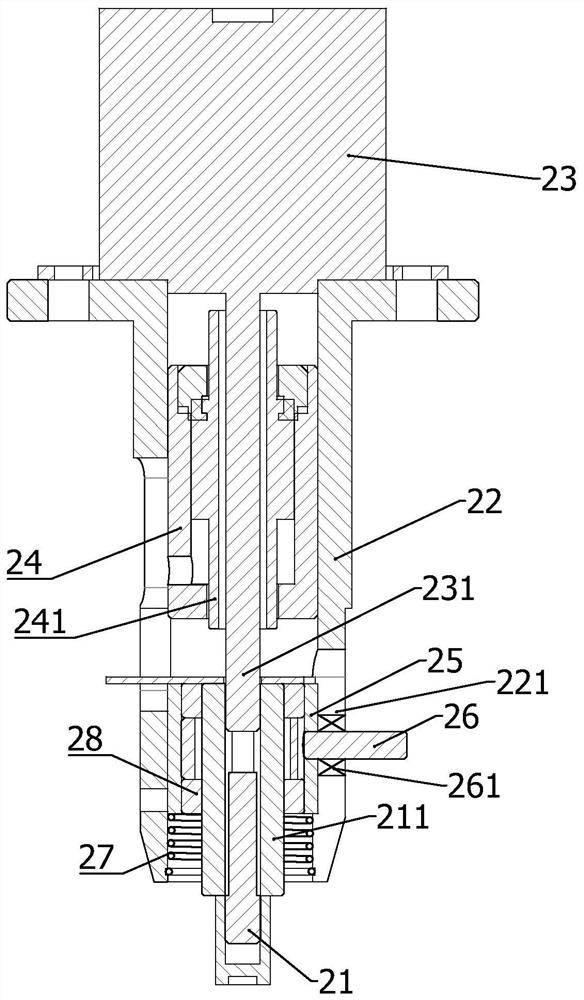

A buckle feeding device for a sewing machine

The invention relates to a button feeding device for a sewing machine, which comprises a machine frame, a button feeding slideway and a turn button mechanism, the button delivery slideway includes a pressure plate that can be adjusted up and down, the turn button mechanism includes a friction column, and the turn button mechanism also includes a sleeve , the friction column protrudes from the lower port of the sleeve; the circular cylinder is used to drive the friction column to move downward, including a retractable and tubular output end; the motor, the output shaft of the motor passes through the output end of the cylinder and is connected with the friction The column is connected by a connecting sleeve, which has a certain up and down movement stroke in the sleeve, and also includes a spring elastically resisting the connecting sleeve. The output end of the circular cylinder drives the connecting sleeve to move downward when it moves; the connecting sleeve is in the sleeve. The stroke of the inner upward movement can be adjusted, and it also includes a limit adjustment assembly for adjusting the upward movement stroke of the friction column. The limit adjustment assembly is set in linkage with the upward and downward adjustment of the pressure plate. The height of buckle-feeding slideway and buckle-turning mechanism can be adjusted synchronously.

Owner:WENZHOU ZHONGKE AUTOMATION EQUIP

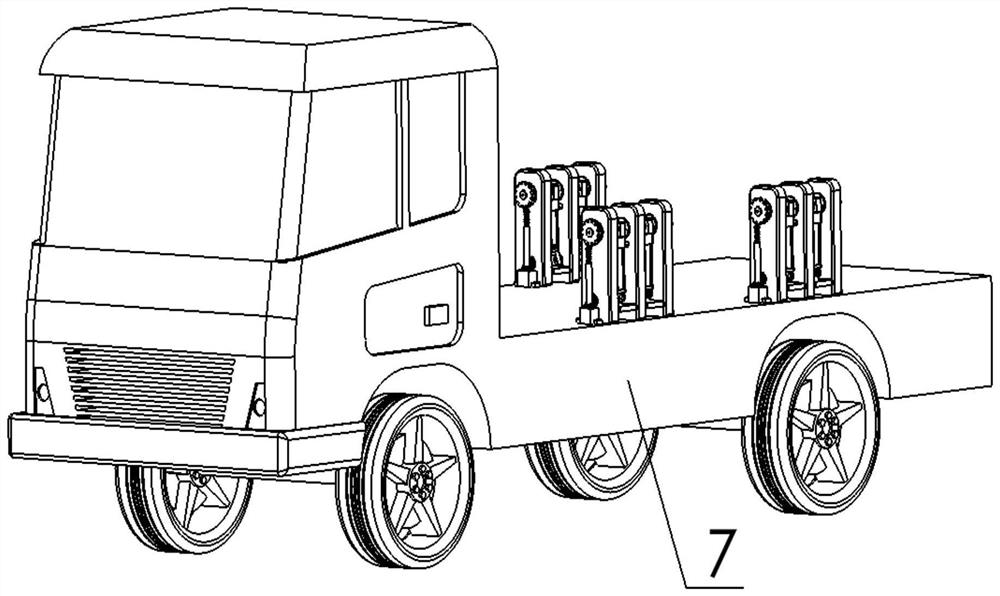

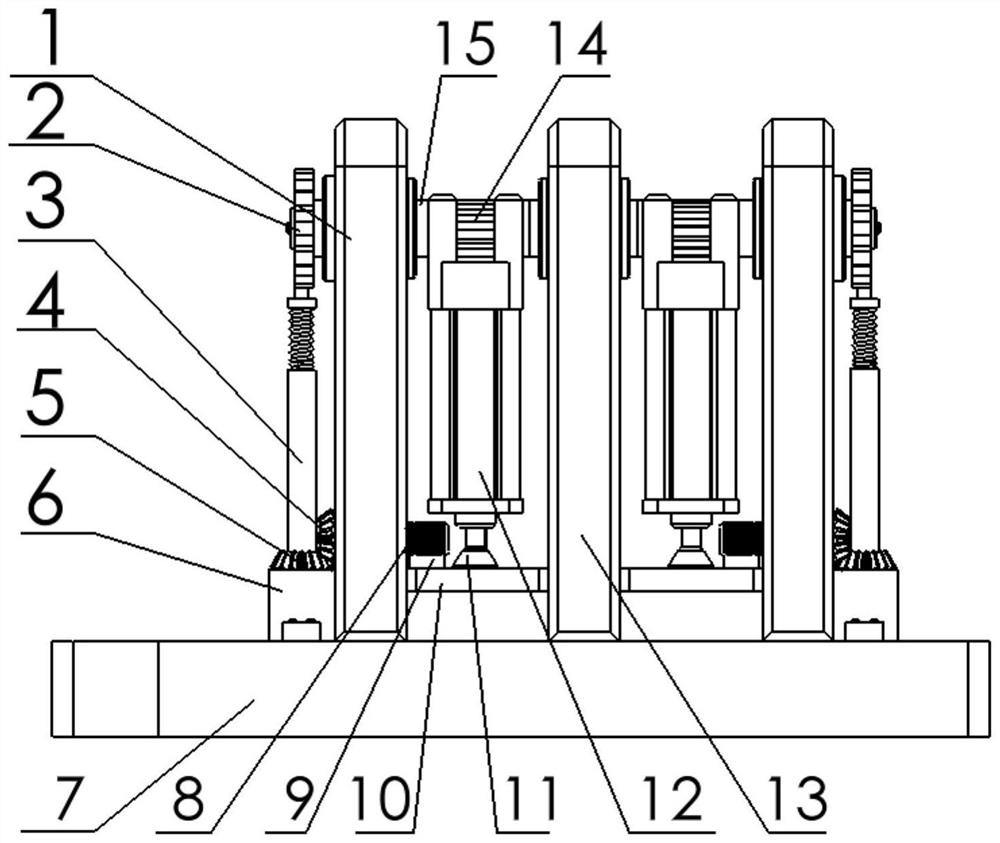

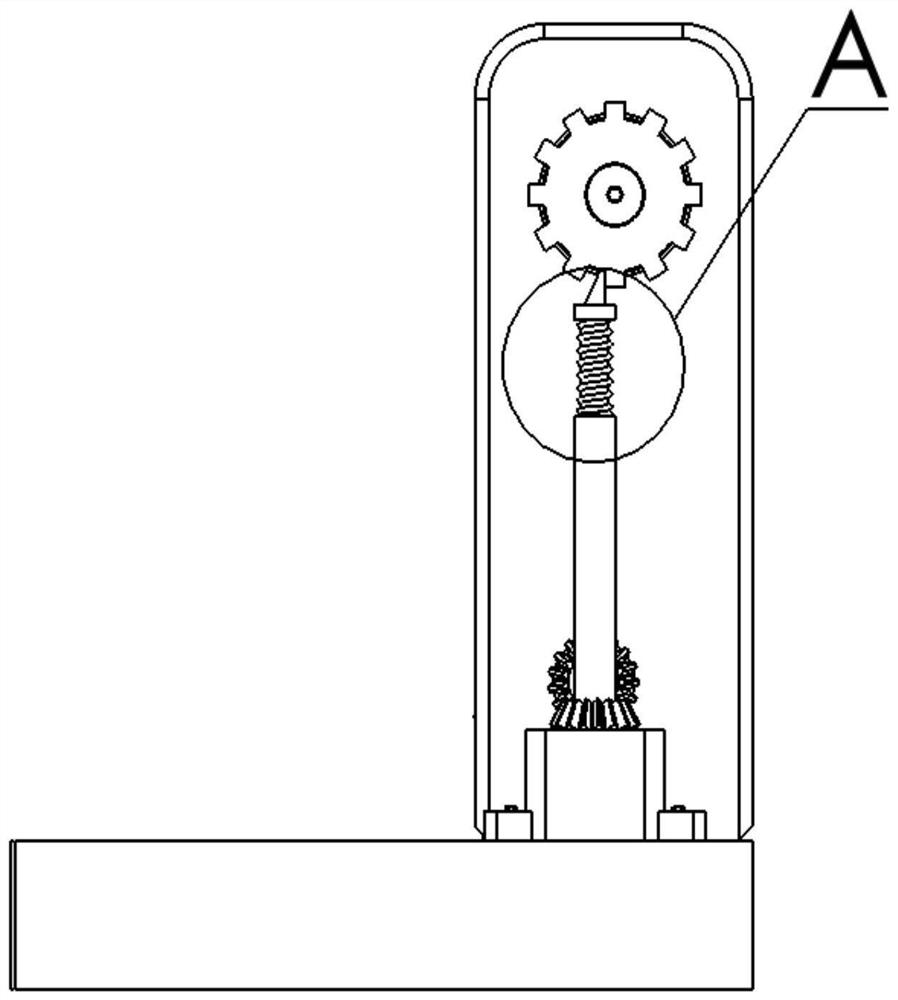

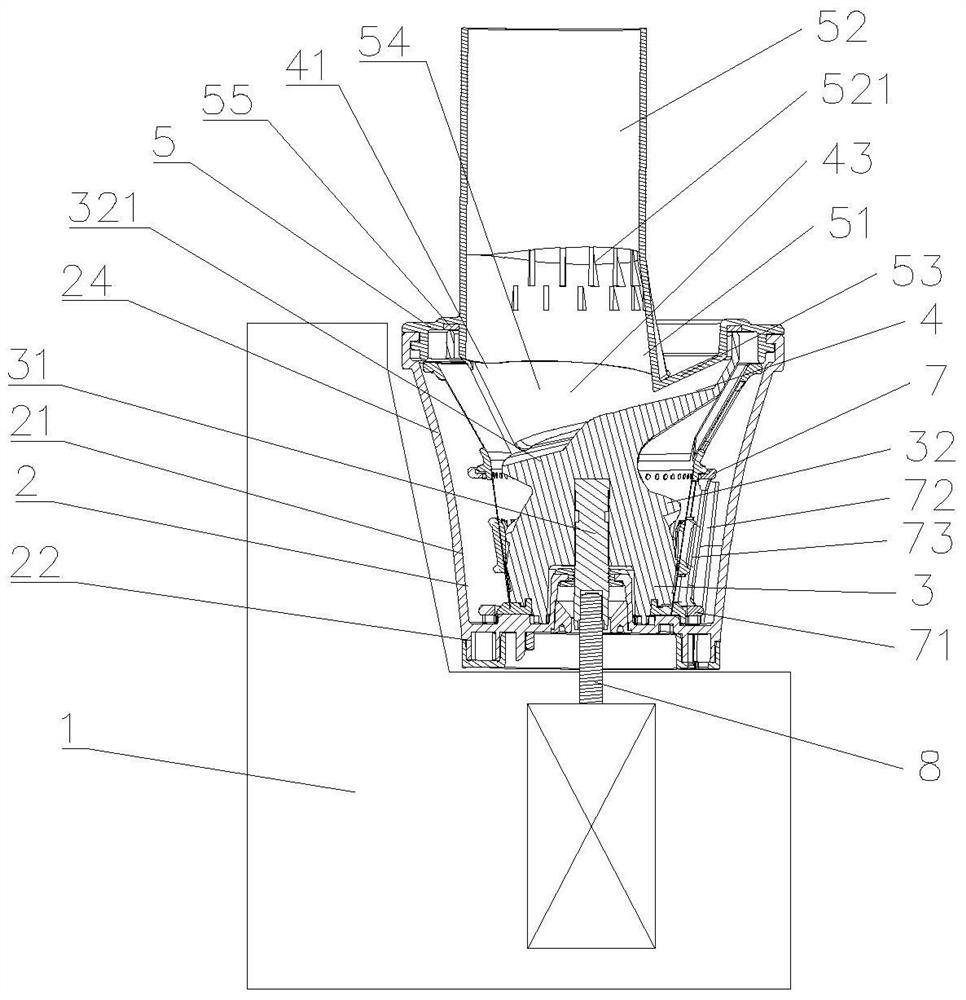

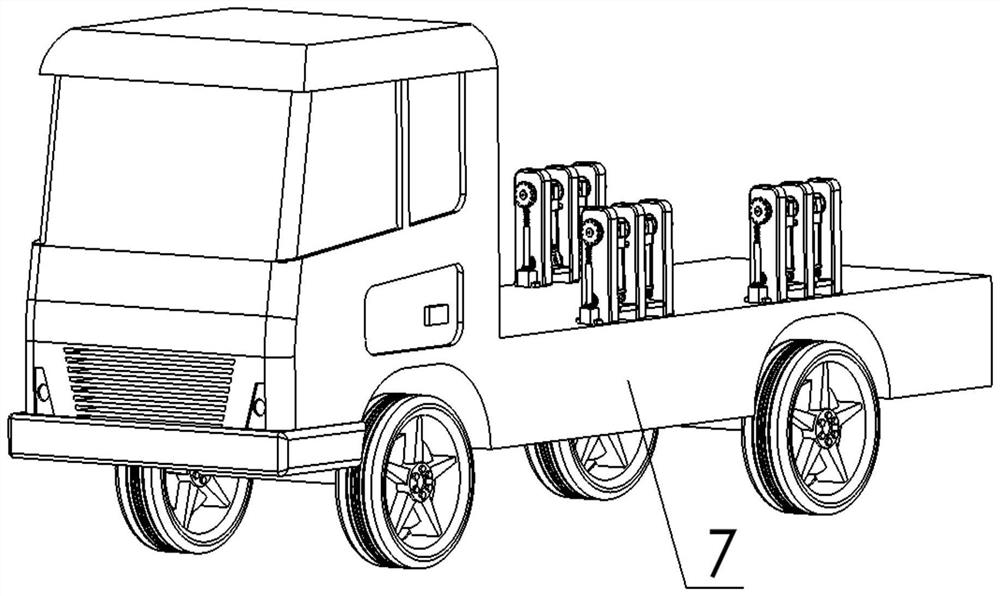

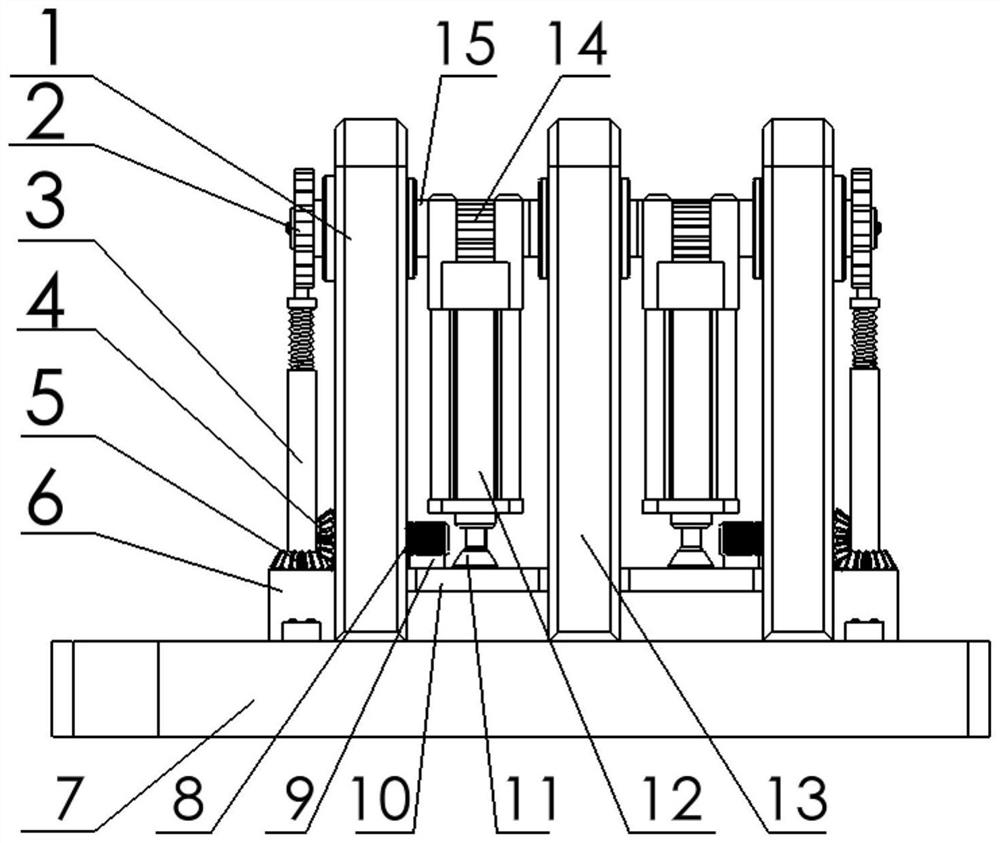

Anti-rollover device and anti-rollover method for trucks

Owner:HANGZHOU DIANZI UNIV

A Juicer with Reliable Structure

ActiveCN107550217BNot easy to pile upEasy to feedStrainersStructural engineeringMechanical engineering

Owner:JOYOUNG CO LTD

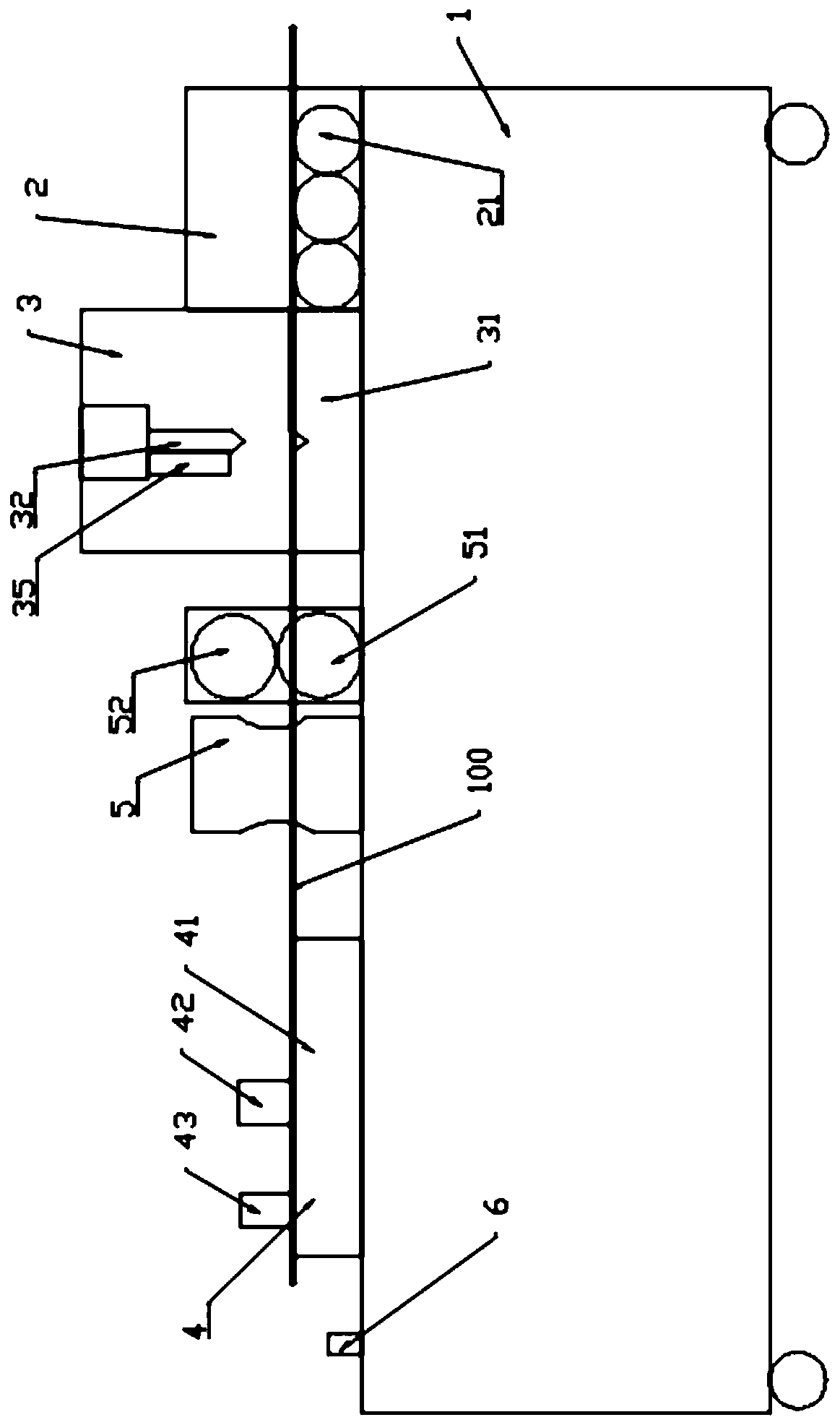

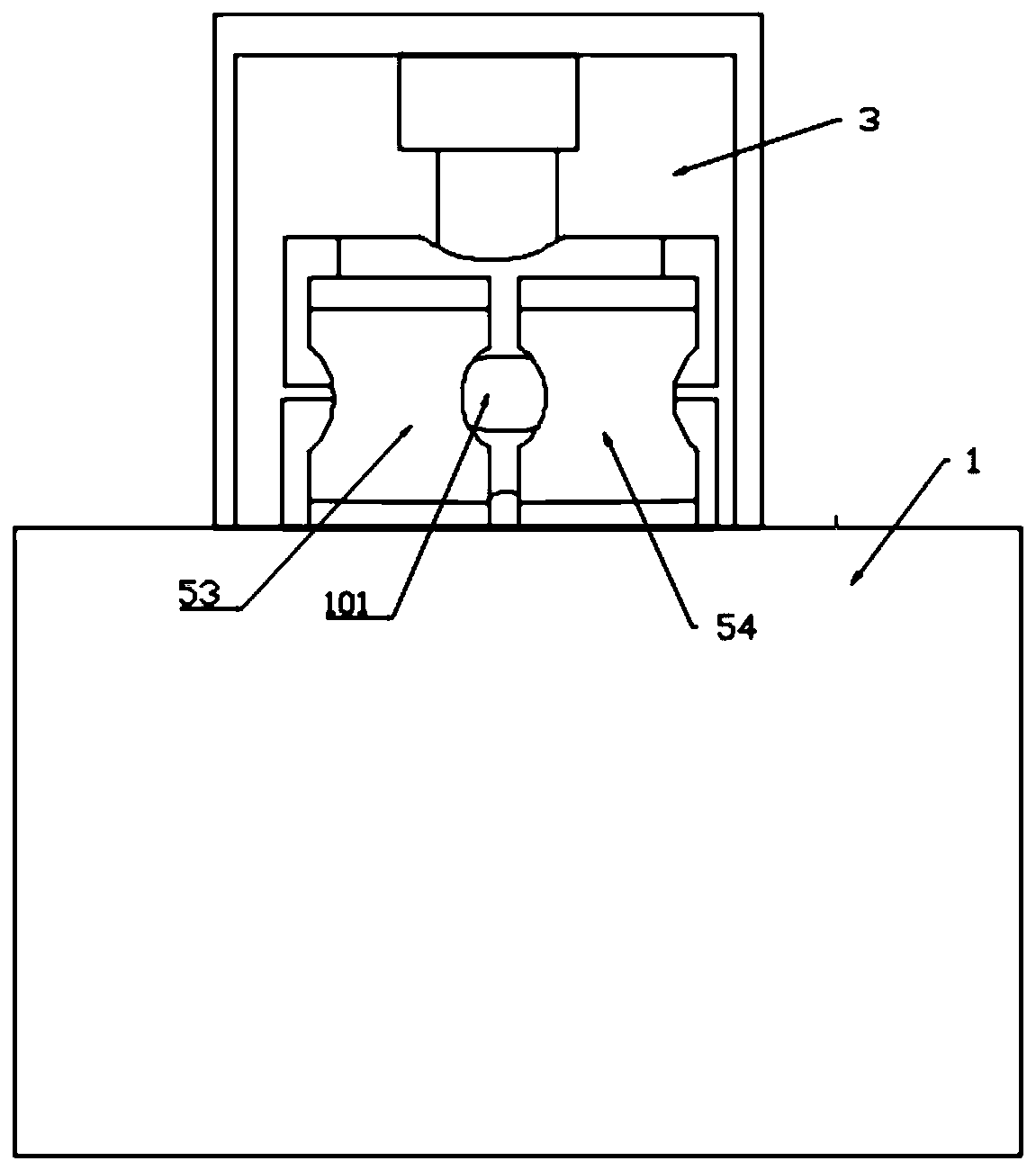

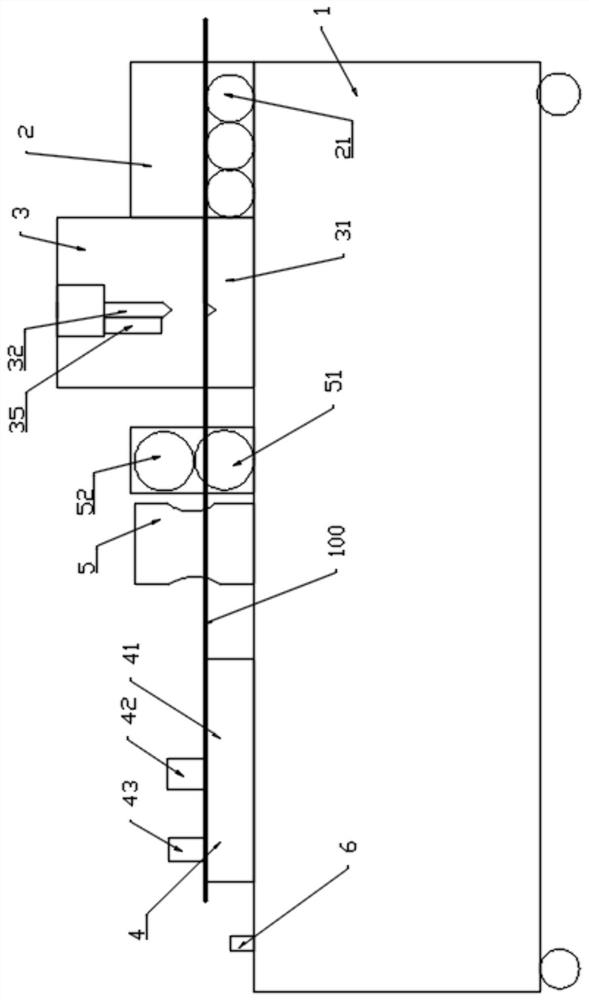

Cutting device capable of bending reinforcing steel bars for house building construction

InactiveCN110976706AImplementation orientationAchieve circumferential limitArchitectural engineeringHouse building

The invention discloses a cutting device capable of bending reinforcing steel bars for building construction. The cutting device comprises a rack, a conveying mechanism, a cutting mechanism, a guide clamping mechanism and a bending mechanism, wherein the conveying mechanism, the cutting mechanism, the guide clamping mechanism and the bending mechanism are arranged on the rack. The conveying mechanism comprises a reinforcing steel bar inlet and a reinforcing steel bar outlet, a conveying roller shaft component is arranged between the reinforcing steel bar inlet and the reinforcing steel bar outlet, and the outlet is opposite to the cutting mechanism. The cutting mechanism comprises a cutting bottom plate and a telescopic cutting tool. An outlet of the cutting mechanism is opposite to the guide clamping mechanism, and an outlet of the guide clamping mechanism is opposite to the bending mechanism. Furthermore, the cutting mechanism comprises the cutting bottom plate and the cutting tool,and a clamping groove for clamping a reinforcing steel bar is formed in the cutting tool. The cutting device achieves integration of cutting and bending of reinforcing steel bars, and can ensure the precision and reliability of cutting and bending.

Owner:HENAN NO 1 CONSTR ENG GRP

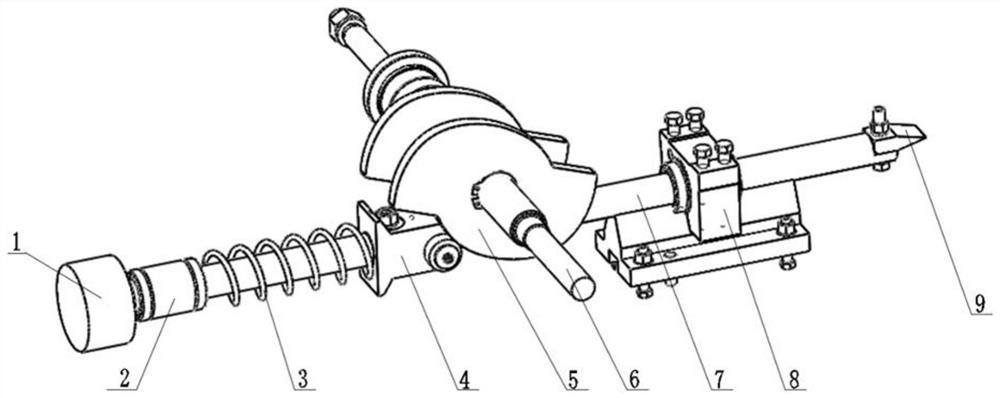

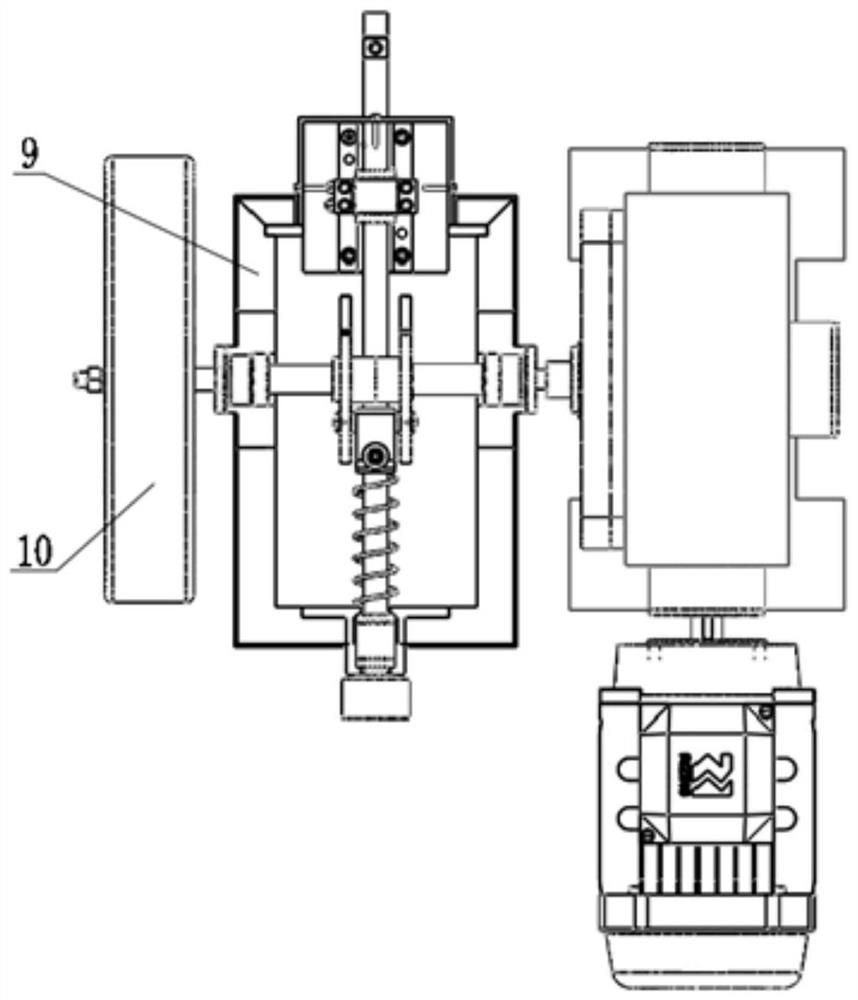

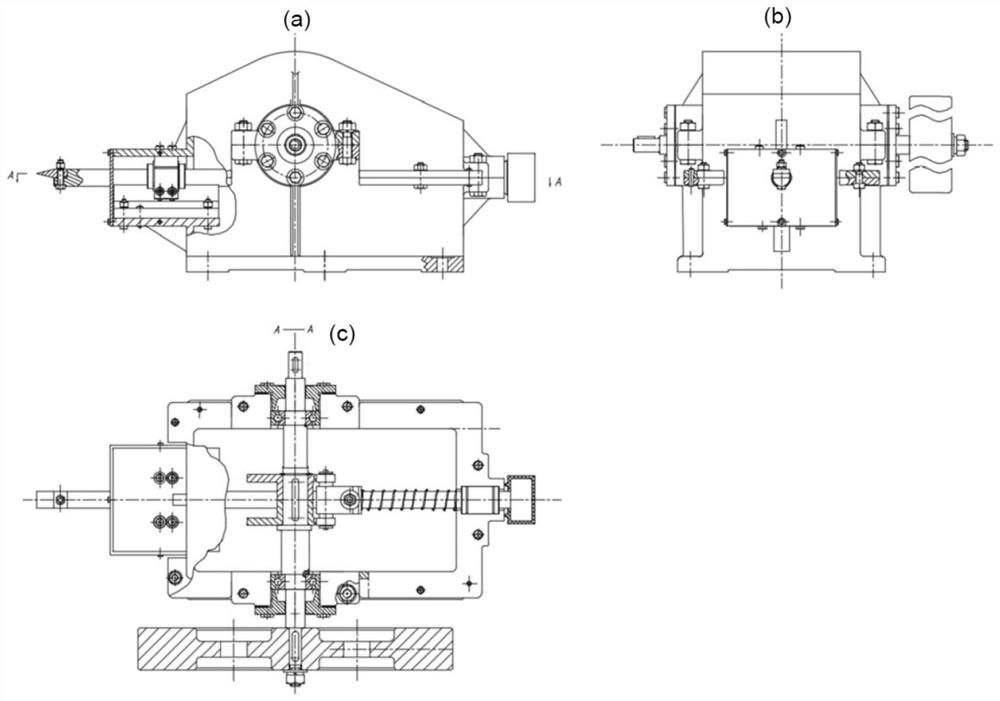

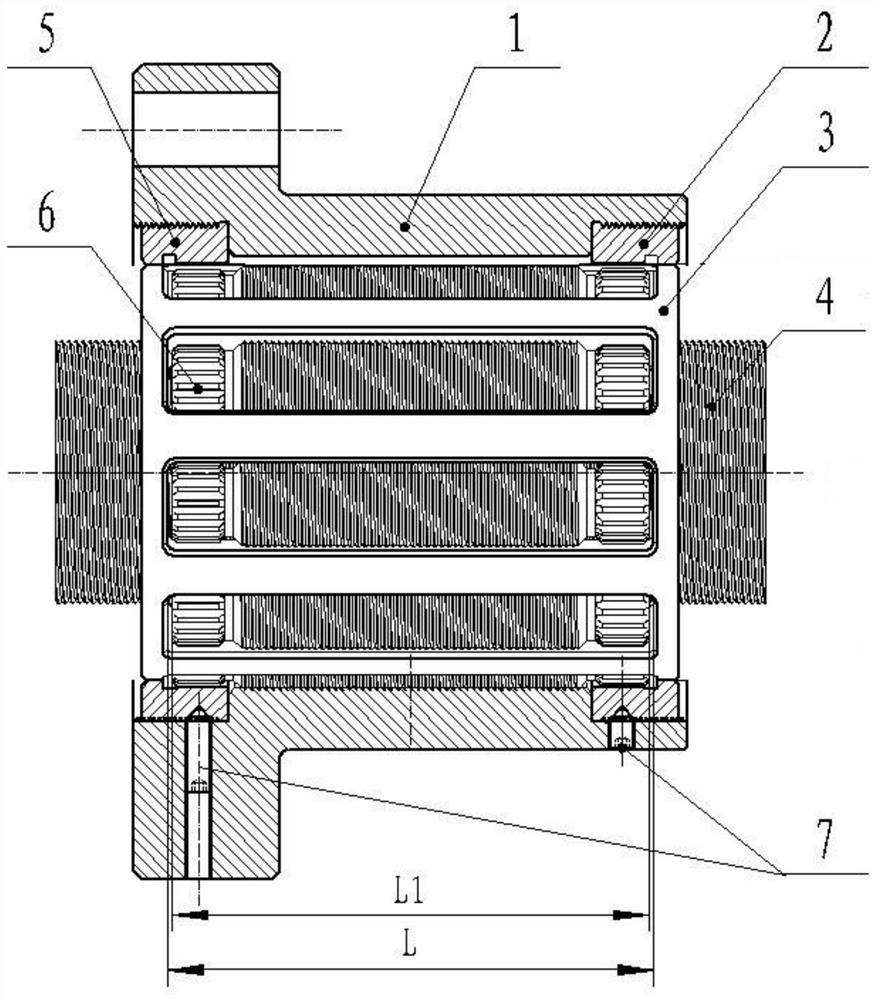

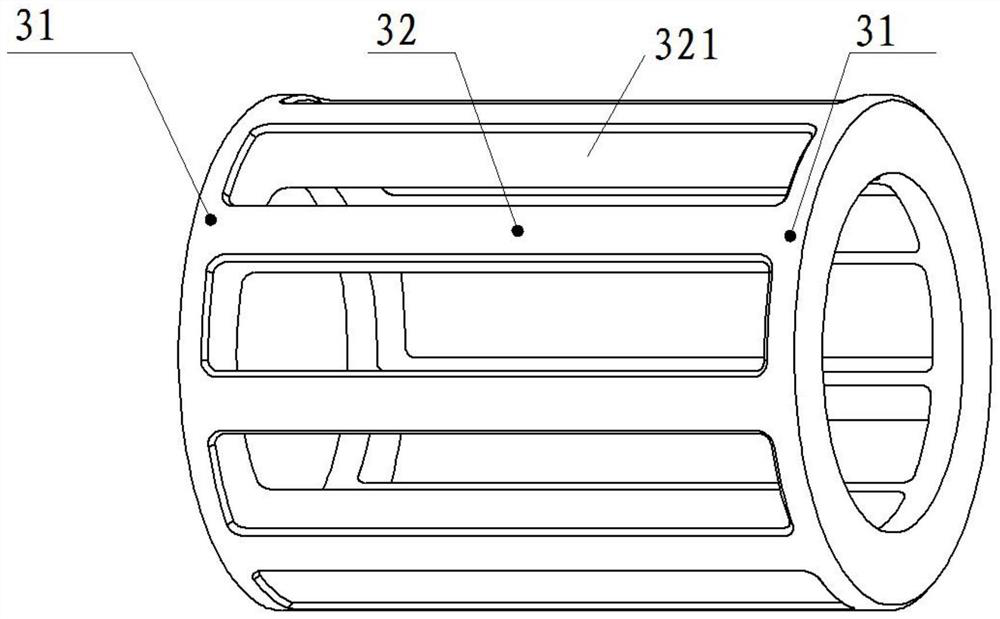

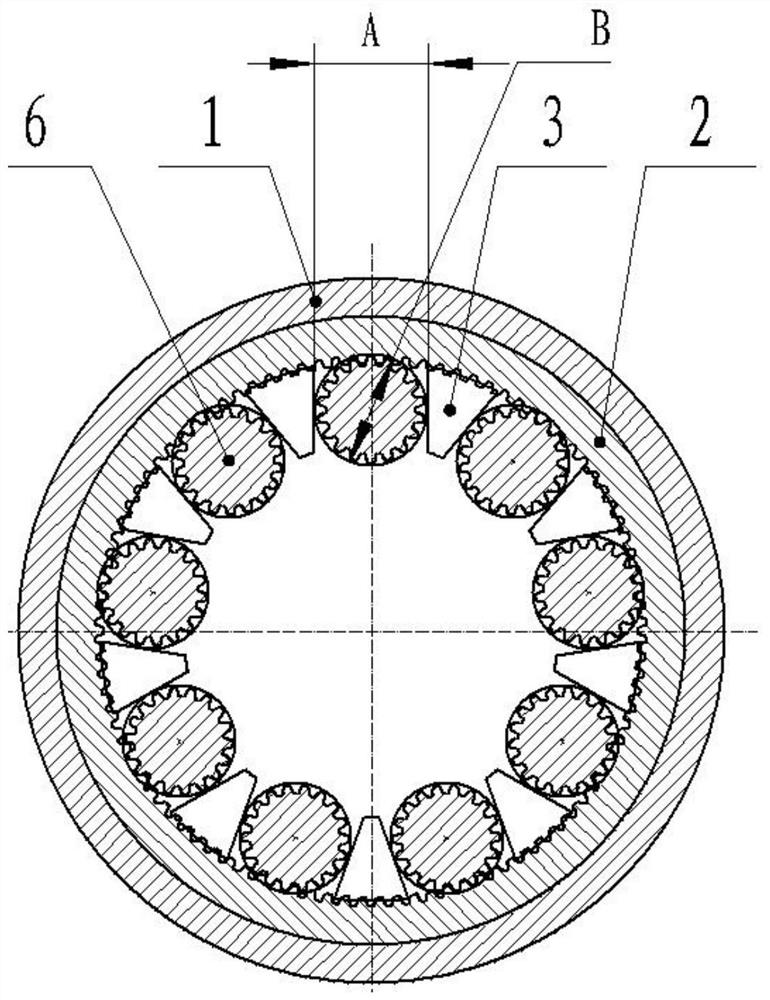

Planetary roller lead-screw pair

The invention relates to a planetary roller lead-screw pair, and belongs to the field of design of planetary roller lead-screw pairs. The planetary roller lead-screw pair comprises a nut, a right gearring, a holder, a lead screw, a left gear ring, n rollers and two locking bolts, wherein the lead screw is axially and horizontally arranged; the outer wall of the lead screw is sleeved with the holder; the n rollers are uniformly embedded into the holder in the circumferential direction, the n rollers are parallel to the axis of the lead screw, and the n rollers are in threaded fit with the leadscrew; the outer wall of the holder is sleeved with the nut; the left gear ring and the right gear ring are arranged on the inner wall of the nut, and the outer walls of the n rollers are sleeved with the left and right gear rings; the left gear ring is correspondingly arranged at the left ends of the rollers in the axial direction, the right gear ring is correspondingly arranged at the right ends of the rollers in the axial direction, and the left gear ring and the right gear ring are fixedly connected with the nut through the two locking bolts respectively; and n is a positive integer. Theplanetary roller lead-screw pair has the characteristics that the structure is simple, the precision is high, the bearing capacity is high, and the movement is stable. The problem that a split type holder cannot limit tilting of the rollers at a high precision is solved, and moreover, the bearing capacity of the lead-screw pair is improved.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

Masher

PendingCN111774130AAchieve circumferential limitEasy to moveGrain treatmentsStructural engineeringMechanical engineering

The invention discloses a masher. The masher comprises a top cover, a base and a container. Two stand columns are bilaterally symmetrically arranged between the top cover and the base. The upper end of each stand column is connected with the lower end face of one side of the top cover, and the lower end of each stand column is connected with the upper end face of one side of the base. An embeddinggroove for partially containing a container is formed in the middle of the upper end surface of the base, and a circumferential limiting structure is arranged between the container and the base. A sleeve pipe is arranged in the middle of the lower end face of the top cover, an ejector rod movably penetrates the sleeve pipe, and the lower end of the ejector rod is in threaded connection with a stamp hammer used for mashing food in the container. At least one spiral groove is formed in the peripheral wall of the ejector rod, and a protrusion used for sliding along the spiral groove is arrangedon the inner wall of the sleeve pipe. A driving mechanism used for driving the ejector rod to move downwards is installed on the top cover, and a reset structure used for driving the ejector rod to move upwards to reset is arranged between the ejector rod and the sleeve pipe. The masher can bring convenience to food mashing, and the purposes of saving time and labor can be achieved.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

A bendable steel bar cutting device for building construction

InactiveCN110976706BImplementation orientationAchieve circumferential limitStructural engineeringRebar

The invention discloses a bendable steel bar cutting device for house construction, comprising a frame, a conveying mechanism, a cutting mechanism, a guiding and clamping mechanism and a bending mechanism arranged on the frame, and the conveying mechanism comprises a steel bar feeding material A conveying roller shaft assembly is arranged between the reinforcement inlet and the reinforcement outlet, the outlet is opposite to the cutting mechanism, and the cutting mechanism includes a cutting bottom plate and a retractable The cutting tool, the outlet of the cutting mechanism is opposite to the guide clamping mechanism, and the outlet of the guide clamping mechanism is opposite to the bending mechanism. And the cutting mechanism includes a cutting bottom plate and a cutting tool, and the cutting tool is provided with a slot for clamping the steel bar. The device of the invention realizes the integrated setting of steel bar cutting and bending, and can ensure the precision and reliability of cutting and bending.

Owner:HENAN NO 1 CONSTR ENG GRP

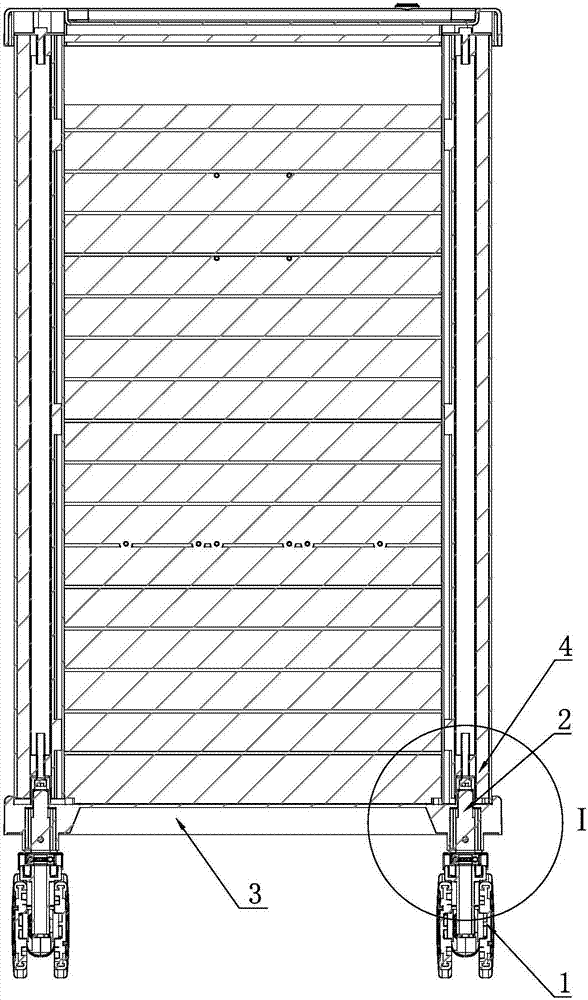

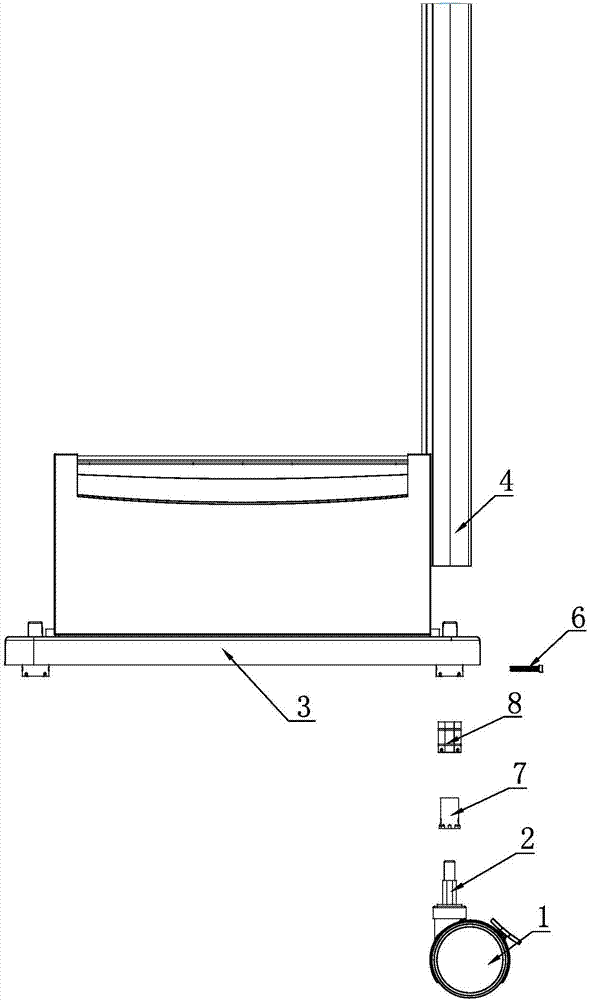

Large-torque medical trolley caster sleeving structure

PendingCN107049675AInhibit sheddingIncrease support lengthNursing accommodationClassical mechanicsEngineering

The invention discloses a large-torque medical trolley caster sleeving structure which comprises casters, caster connecting shafts, a frame bottom plate, frame pull tubes, fastening screws, axial pins and peripheral limit sleeves. The caster connecting shafts comprise peripheral limit shaft sections and torque enhancement shaft sections, upper positioning sleeve seats and lower positioning sleeve seats are arranged at four corners of the frame bottom plate, the outer diameter of each upper positioning sleeve seat corresponds to an inner hole of each frame pull tube, the peripheral limit sleeves are arranged in inner holes of the lower positioning sleeve seats, the sectional shape of an inner hole of each peripheral limit sleeve corresponds to that of each peripheral limit shaft section, a connecting nut is arranged in an inner hole of each frame pull tube, the lower ends of the frame pull tubes are inserted into the upper positioning sleeve seats of the frame bottom plate and axially and fixedly connected by the fastening screws, and the caster connecting shafts and the peripheral limit sleeves are axially limited by the axial pins. The bearing strength of the casters is enhanced, the casters can be conveniently sleeved in a bare-handed manner on site, loosening, falling and joint breakage of the casters are avoided when large resistance is applied to the casters, and the casters are long in service life.

Owner:杨骏成

Intelligent street lamp with good lighting effect

InactiveCN111664395AAchieve circumferential limitStable and reliable movement up and downMechanical apparatusLighting support devicesEngineeringMechanical engineering

The invention discloses an intelligent street lamp with the good lighting effect. The intelligent street lamp comprises a lamp pole, a supporting base is fixedly welded to the upper end of the lamp pole, a lamp holder is fixed to the middle of the upper end face of the supporting base, a bulb is installed on the lamp holder, the bulb and the lamp holder are covered with a lampshade, the lampshadeis fixed to the supporting base, a reflector is fixed to the inner top of the lampshade, a plurality of reflective protrusions distributed in an array mode are integrally formed on the lower surface of the reflector, and each reflective protrusion is of an inverted-circular-truncated-cone-shaped structure. After the reflector is fixed to the inner top of the lampshade and the reflecting protrusions are arranged on the lower surface of the reflector, the reflector and the reflective protrusions can reflect light emitted by the bulb downwards and towards the side face, the reflected light can penetrate out of the side face of the lampshade, and therefore the lighting effect of the street lamp can be improved.

Owner:沈国荣

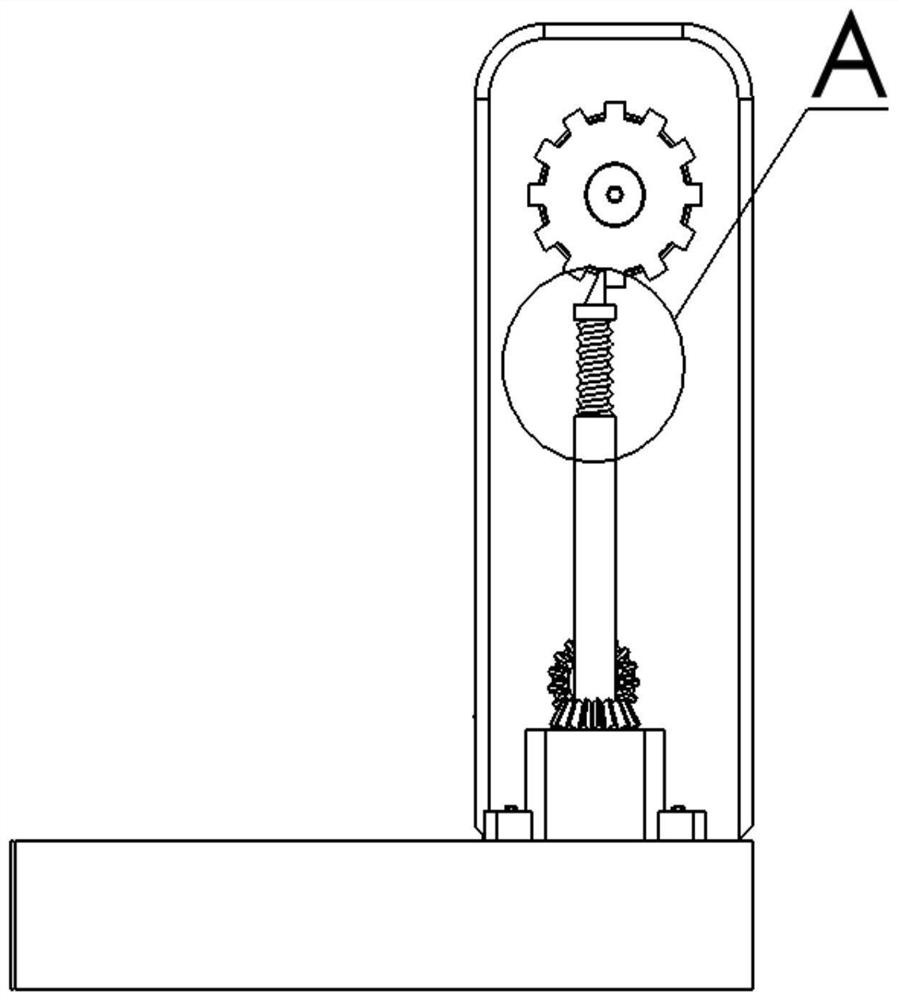

Truck rollover prevention device and rollover prevention method thereof

The invention discloses a truck rollover prevention device and a rollover prevention method thereof. The truck rollover prevention device comprises a fixed supporting system and a sensor control system. The fixed supporting system comprises a plurality of fixed supporting units which are equally divided into two groups and are arranged on two sides; each fixed supporting unit comprises a transmission main shaft, a supporting assembly and a circumferential limiting assembly; each supporting assembly comprises an electric push rod assembly, an electric cylinder and an electric cylinder foot support, wherein the electric push rod assembly comprises an electric push rod, a spherical hinge and a supporting plate; each circumferential limiting assembly comprises a bidirectional driving ratchet wheel, a pawl, a spring, a pawl rotating shaft, a bevel gear I, a bevel gear II, a bearing seat and a driving motor; and the sensor control system comprises a pressure sensor and a tilt angle sensor. When a truck rolls over, the truck body is supported, only when the pressure of wheels on one side of the truck disappears and the inclination angle of the truck body exceeds the preset inclination angle of the tilt angle sensor, the device can be triggered, and mistaken touch of the device is avoided.

Owner:HANGZHOU DIANZI UNIV

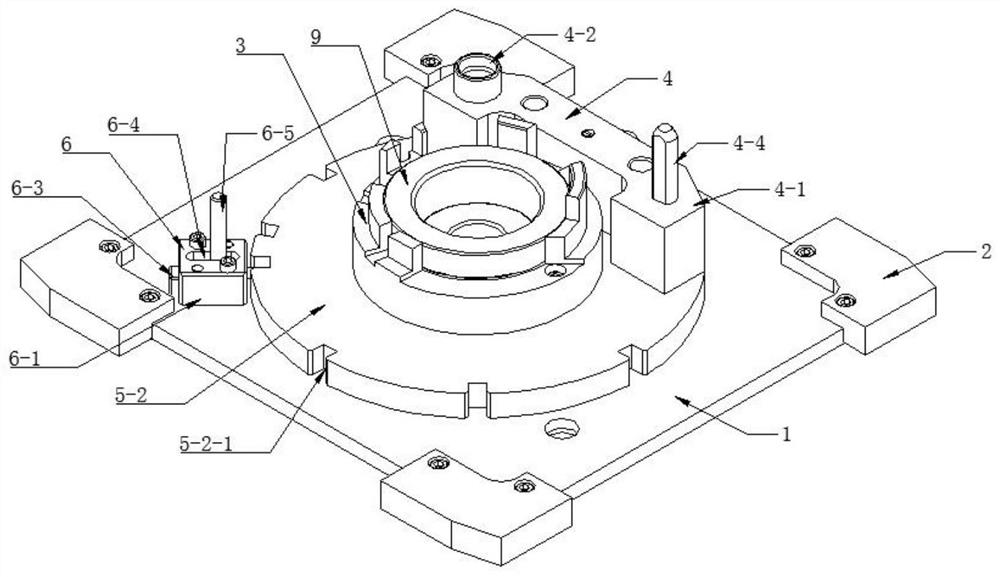

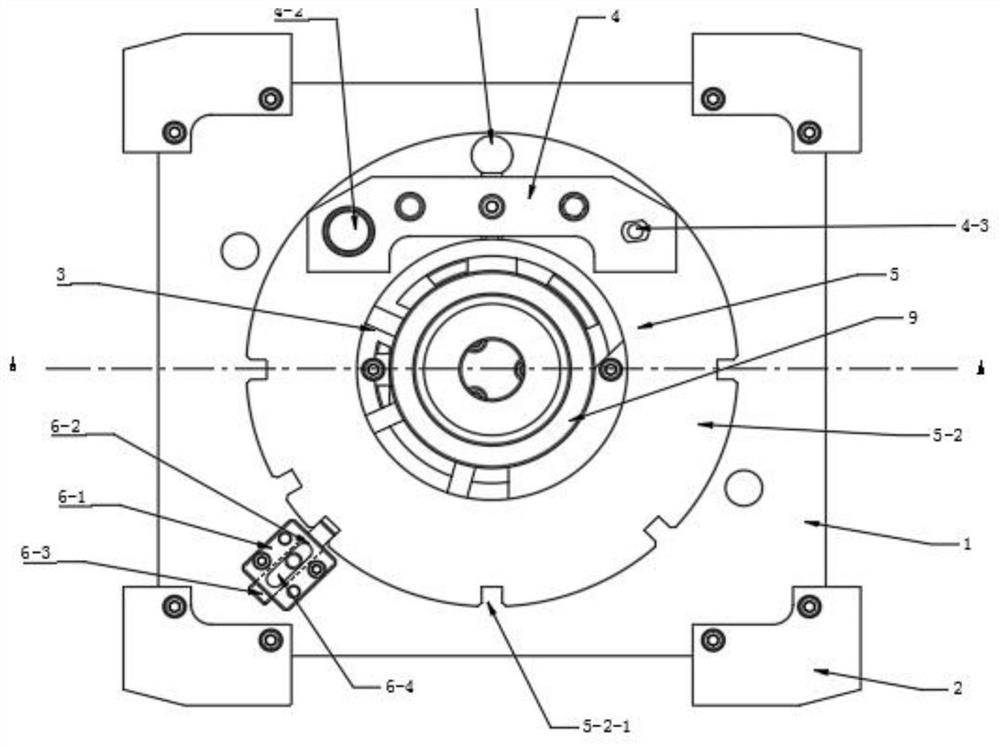

Engine assembling follow fixture

ActiveCN111890266AAchieve circumferential limitEasy to fixWork holdersElectric generatorAutomotive engineering

The invention relates to an engine assembling follow fixture. An engine comprises a belt wheel at the end, and an end cover adjacent to the belt wheel, and the end cover is provided with two suspension loop holes. The assembling follow fixture comprises a support plate and stop blocks installed at four corners of the support plate, and the center of the support plate is fixedly provided with a rotary device and a positioning device fixing the rotary device; the rotary device is further provided with a positioning ring, a cushion block and a positioning pin seat. The engine assembling follow fixture achieves two-point positioning through the cushion block and the positioning pin seat, thus, installing of the engine on the assembling follow fixture can be more stable, when the engine flows along with the fixture, swinging along with the fixture is avoided, and the engine can still keep in the specific direction when being conveyed to an assembling station. By arranging the rotary deviceand the positioning device, workers can conveniently correct the direction of the engine, and thus, the engine assembling follow fixture has wider adaptability.

Owner:DONGFENG AUTOMOBILE ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com