Assembling assembly and method of dust information acquisition assembly, dust collection cup and cleaning device

A technology for assembling components and assembly methods, which is applied to cleaning equipment, chemical instruments and methods, cleaning methods using tools, etc., can solve problems such as shaking in the clamping area, increase accuracy, improve test accuracy, and ensure measurement The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

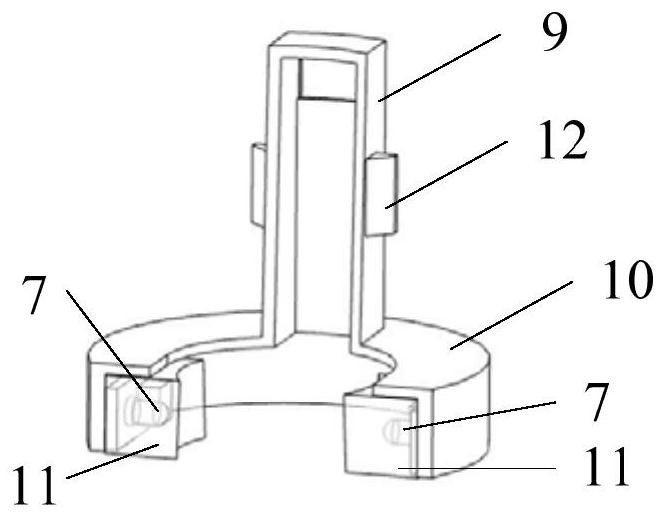

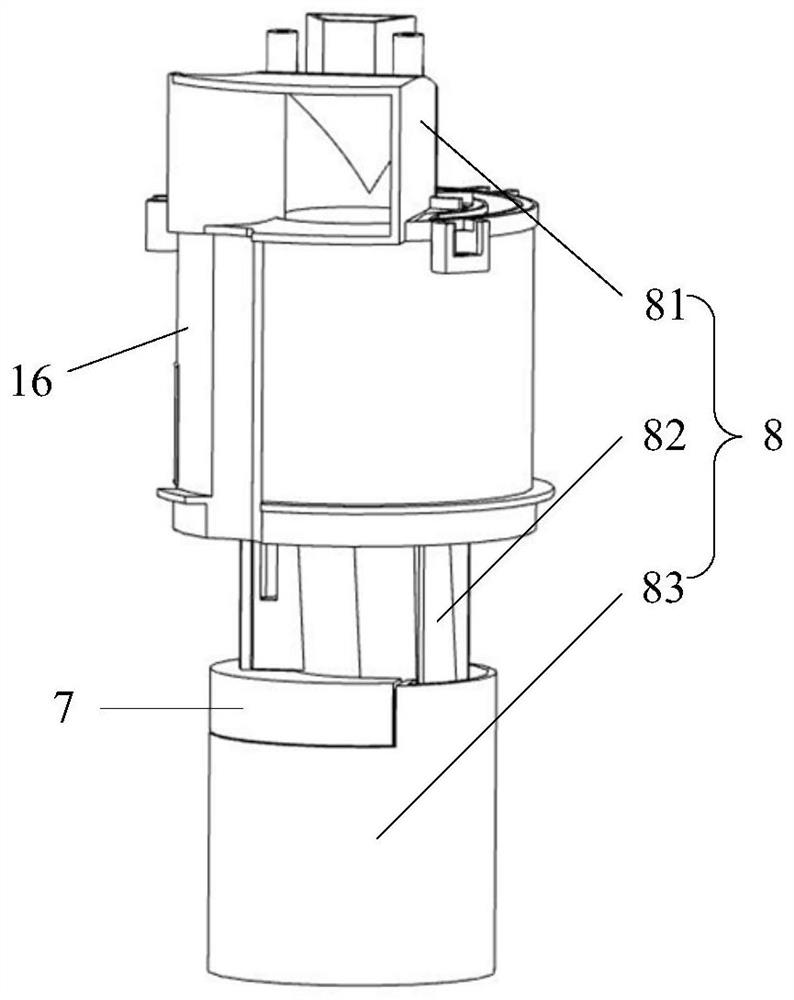

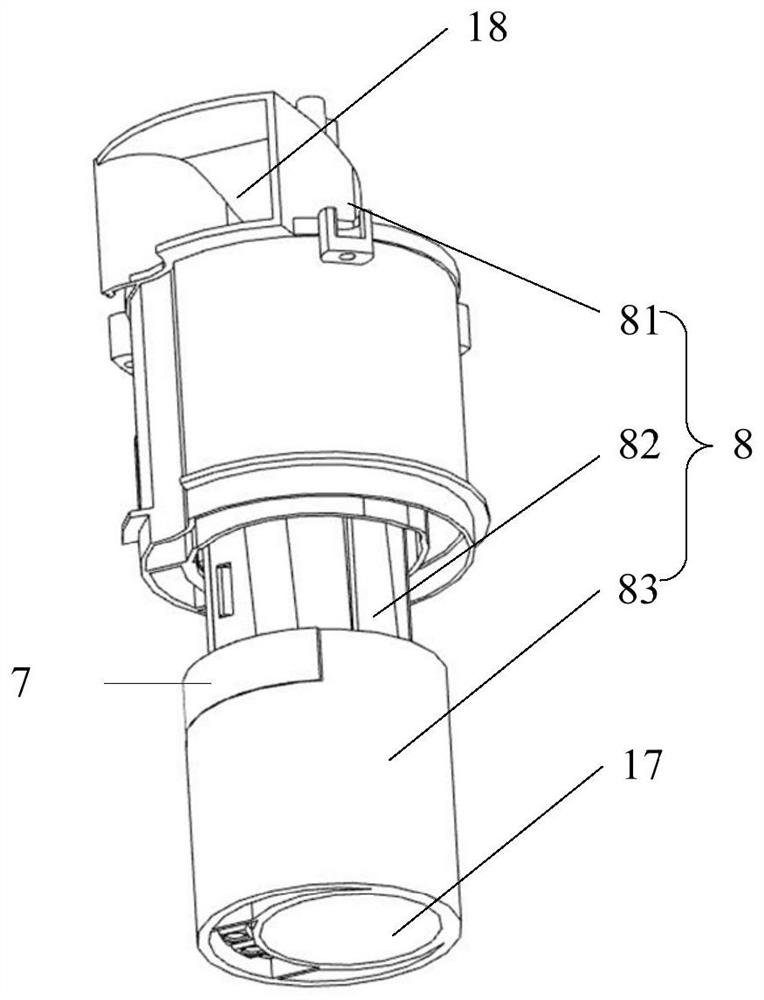

[0062] This embodiment provides an assembly component of a dust information acquisition component, see Figure 1 to Figure 7 , including a fluid pipeline 8 and a bracket, the bracket is fixed on the side wall of the fluid pipeline 8, and the dust information acquisition component 7 is fixed on the side of the bracket facing the side wall of the fluid pipeline 8, so that the dust information acquisition component 7 is assembled on the fluid pipeline on road 8.

[0063] During implementation, the dust information acquisition component 7 is clamped between the fluid pipeline 8 and the bracket, and the dust information acquisition component 7 faces into the fluid pipeline 8, so that the dust amount of the fluid in the fluid pipeline 8 can be obtained, and then can be obtained according to The amount of dust adjusts the suction power of the cleaning device.

[0064] Compared with the prior art, in the assembly assembly of the dust information acquisition assembly provided in this ...

Embodiment 2

[0076] This embodiment provides an assembly method of the dust information acquisition component 7, using the assembly component of the dust information acquisition component provided in Embodiment 1, the above assembly method includes the following steps:

[0077] Fix the dust information acquisition component 7 on the side of the bracket facing the side wall of the fluid pipeline 8;

[0078] Along the radial direction of the fluid pipeline 8 , the bracket is moved toward the fluid pipeline 8 so that the bracket is assembled on the fluid pipeline 8 .

[0079] Compared with the prior art, the beneficial effect of the assembly method of the dust information acquisition component 7 provided by this embodiment is basically the same as that of the assembly component of the dust information acquisition component provided by the first embodiment, and will not be repeated here.

[0080] Exemplarily, the bracket includes a first sub-frame 9, a second sub-frame 10 and buckles 12, the f...

Embodiment 3

[0086] This embodiment provides a dust cup, see Figure 8 to Figure 9 , including a cup body, a dust information acquisition component 7 and the assembly component provided in Embodiment 1, the dust information acquisition component 7, a fluid pipeline 8 and a bracket are all arranged in the cup body.

[0087] Compared with the prior art, the beneficial effects of the dust cup provided in this embodiment are basically the same as those of the assembly assembly of the dust information acquisition assembly provided in Embodiment 1, and will not be repeated here.

[0088] In order to prevent the dust in the cup body 1 from flowing backward, the above-mentioned dust collection cup also includes a dust cup inner tube 2 and a dust-proof part 3 arranged in the cup body 1, and the dust-proof part 3 is detachably socketed with the top end of the dust cup inner tube 2 . In this way, the inner pipe 2 of the dust cup is detachably connected to the dust-shielding part 3, and when the dust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com