Cutting device capable of bending reinforcing steel bars for house building construction

A cutting device and steel bar technology, applied in the field of integrated machinery, can solve the problems of fixed bracket wear, up and down swing or left and right swing, unqualified products, etc., to achieve the effect of ensuring accuracy, ensuring stability, and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

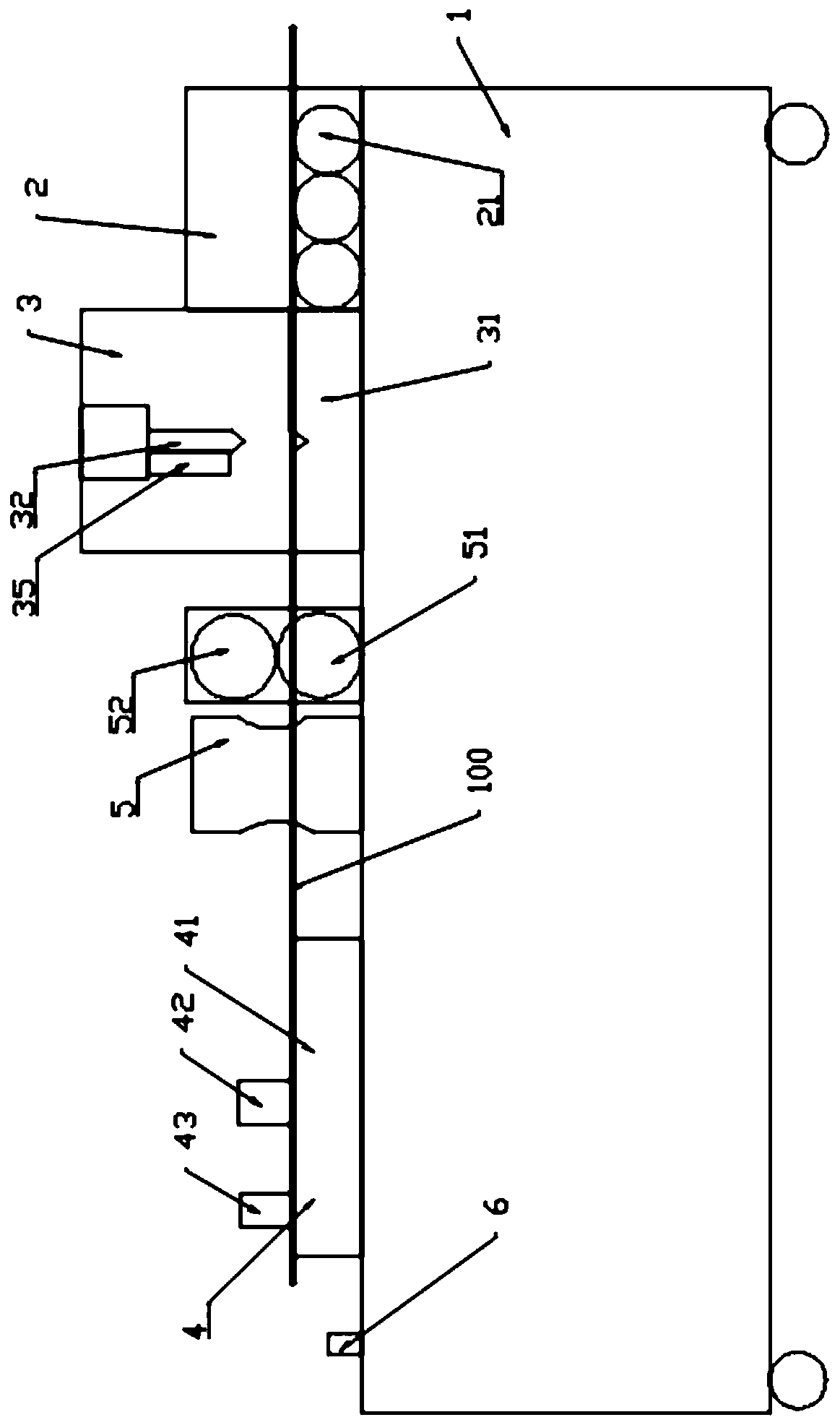

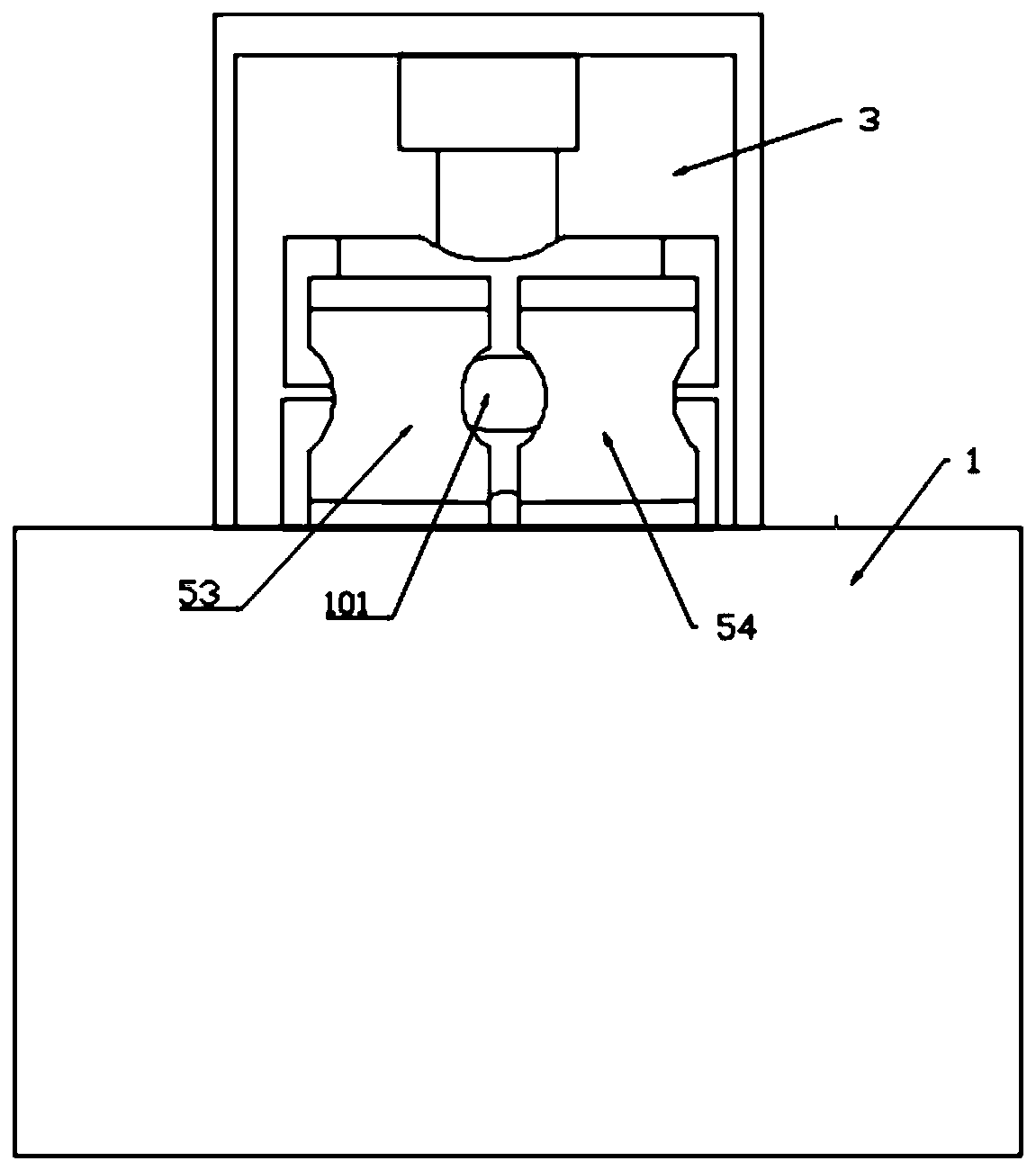

[0024] Example: such as Figure 1-4 As shown, a bendable steel bar cutting device for building construction includes a frame 1 and a conveying mechanism 2 , a cutting mechanism 3 and a bending mechanism 4 arranged on the frame. Wherein, the conveying mechanism includes a steel bar inlet and a steel bar outlet, and a conveying roller assembly is arranged between the steel bar inlet and the steel bar outlet. The conveying roller assembly includes a plurality of rolling shafts 21 arranged side by side in a transverse direction, and the steel bar 100 is transported to the subsequent cutting mechanism and bending mechanism through the rolling of the roller shafts.

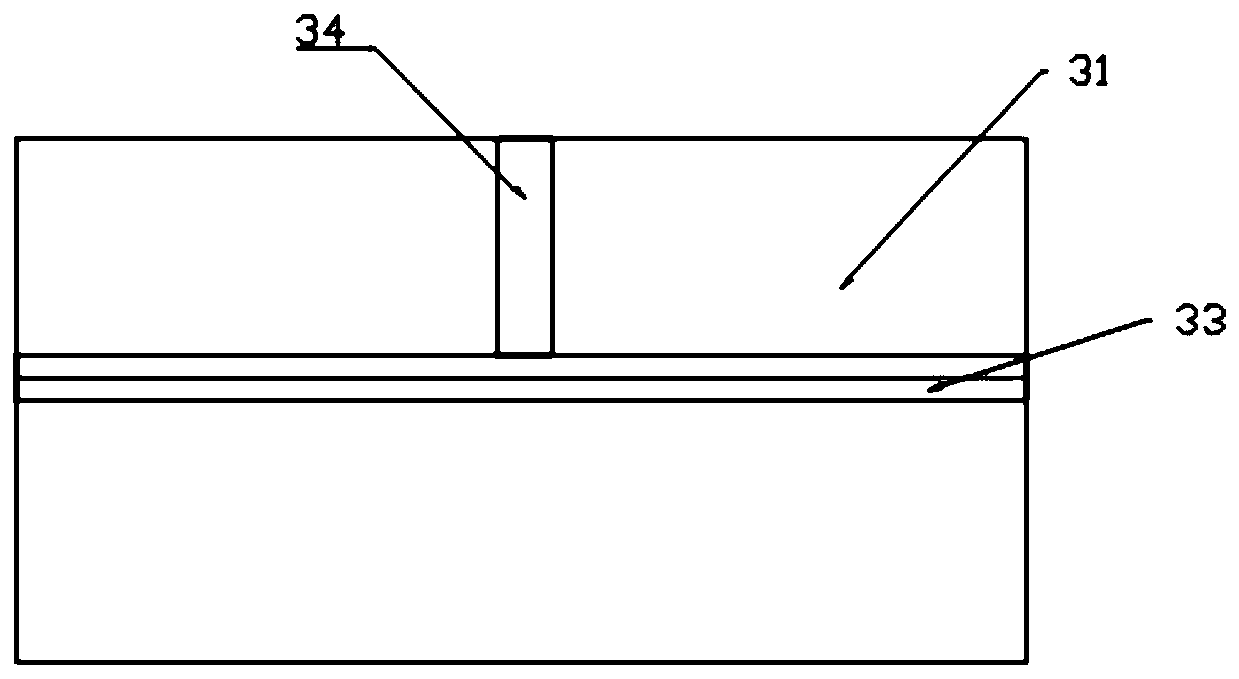

[0025] The cutting mechanism 3 includes a cutting base 31 and a retractable cutting knife 32 located on the top of the cutting base. The cutting base plate is placed horizontally, and a transverse slot 33 is arranged on the cutting base plate, and the cutting tool is located above the cutting base plate and opposite to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com