Vacuum pipeline magnetic suspension train hybrid EMS supporting structure

A technology of vacuum pipes and supporting structures, which is applied in the direction of tracks, roads, motor vehicles, etc., can solve the problems of high energy consumption, complex control system, and high construction cost of maglev trains, and achieve low levitation power consumption, compact and simple structure, The effect of smooth running of the train

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

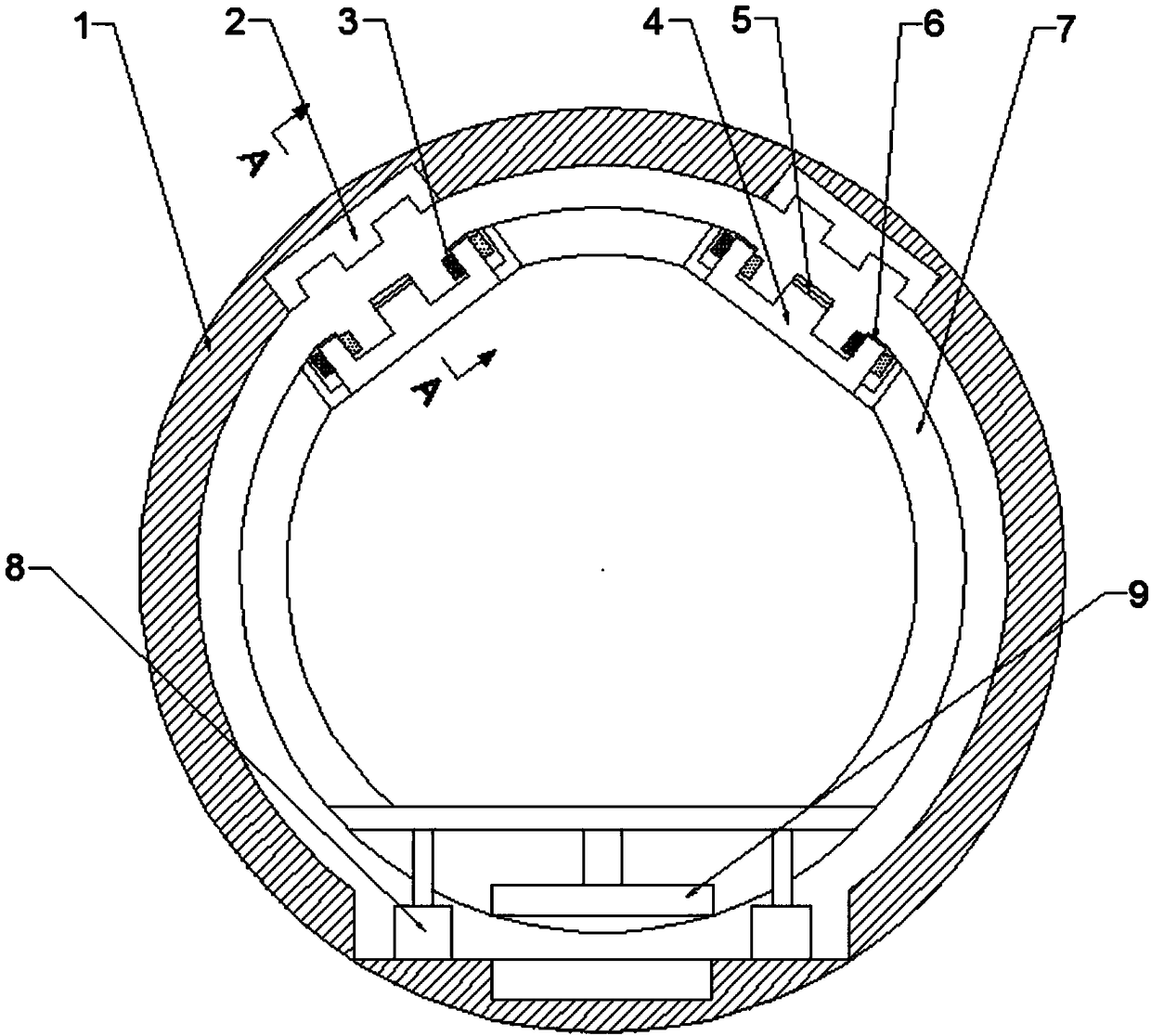

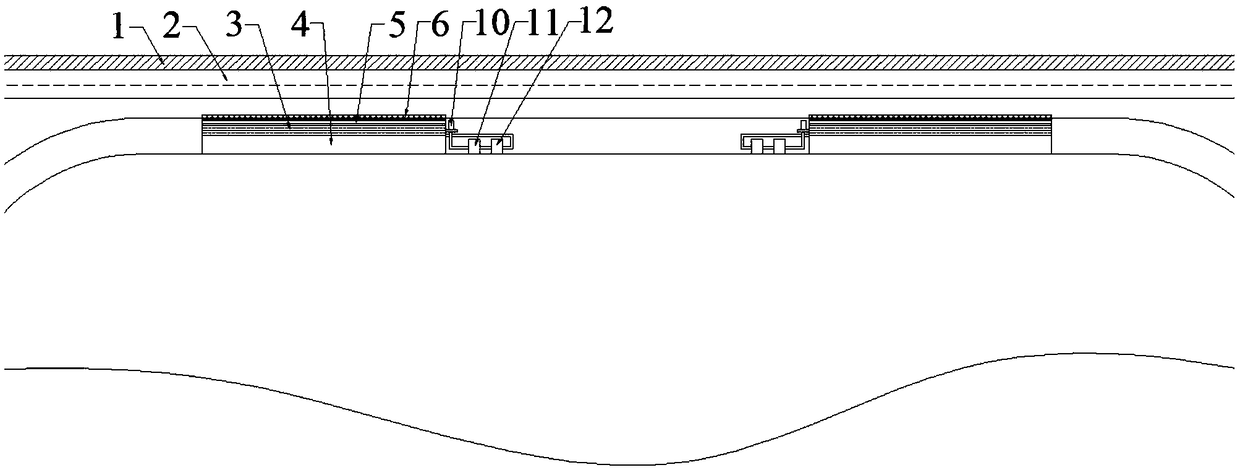

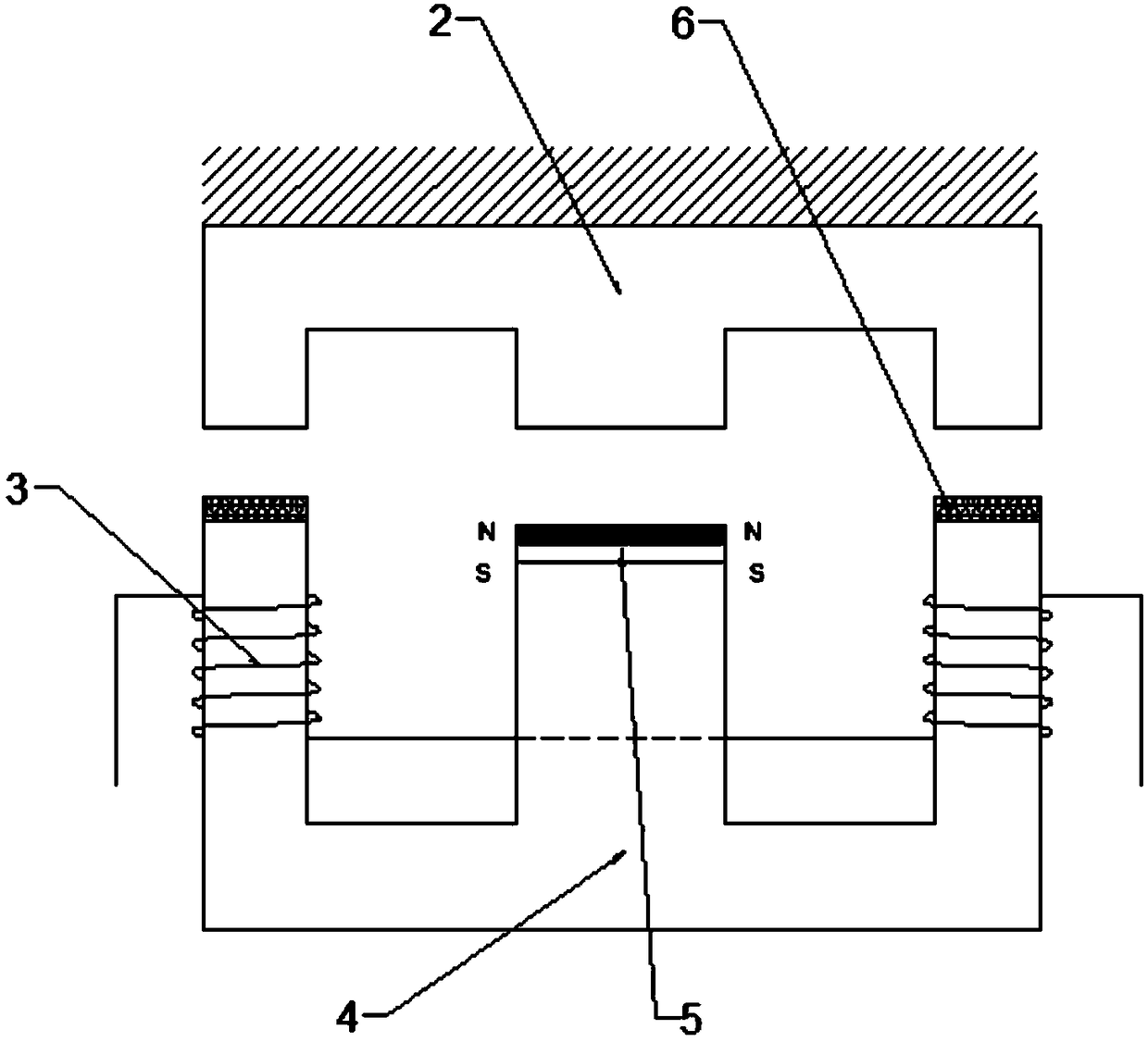

[0031] refer to figure 1 As shown in Figure 4, the hybrid EMS support structure of the vacuum tube magnetic levitation train in an embodiment provided by the present invention includes a vacuum tube 1, a capsule train 7 and a supporting guide part, the capsule train 7 is set in the vacuum tube 1, and the track armature 2 Arranged on the inner wall of the vacuum pipeline 1 along the length direction of the vacuum pipeline 1, the track armature 2 is embedded in the inner wall of the vacuum pipeline 1, and a supporting guide part is provided between the vacuum pipeline 1 and the track armature 2,

[0032] Wherein, the supporting guide part comprises electromagnetic coil 3, electromagnet core 4, permanent magnet 5, safety support wheel 8, and electromagnet core 4 is arranged on the upper end of capsule train 7, and safety support wheel 8 is arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com