A connection structure for motor output shaft and rotating shaft

A connection structure and output shaft technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of the shaft body beating, easy to break, loose connection between the motor output shaft and the rotating shaft, etc., to avoid shaft looseness and concentricity The effect of consistency and avoiding breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following embodiments are combined with the accompanying drawings to elaborate on the present invention.

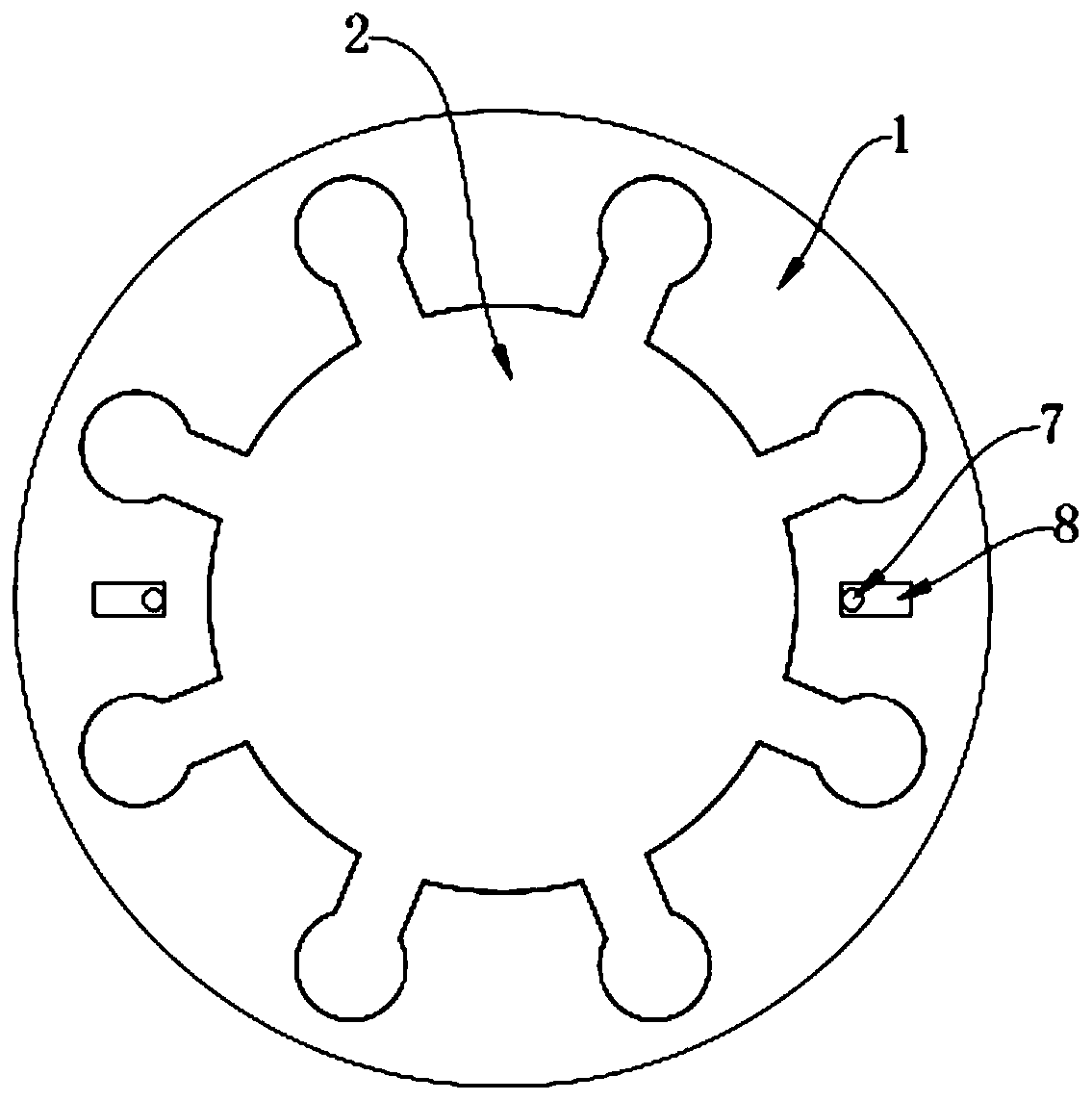

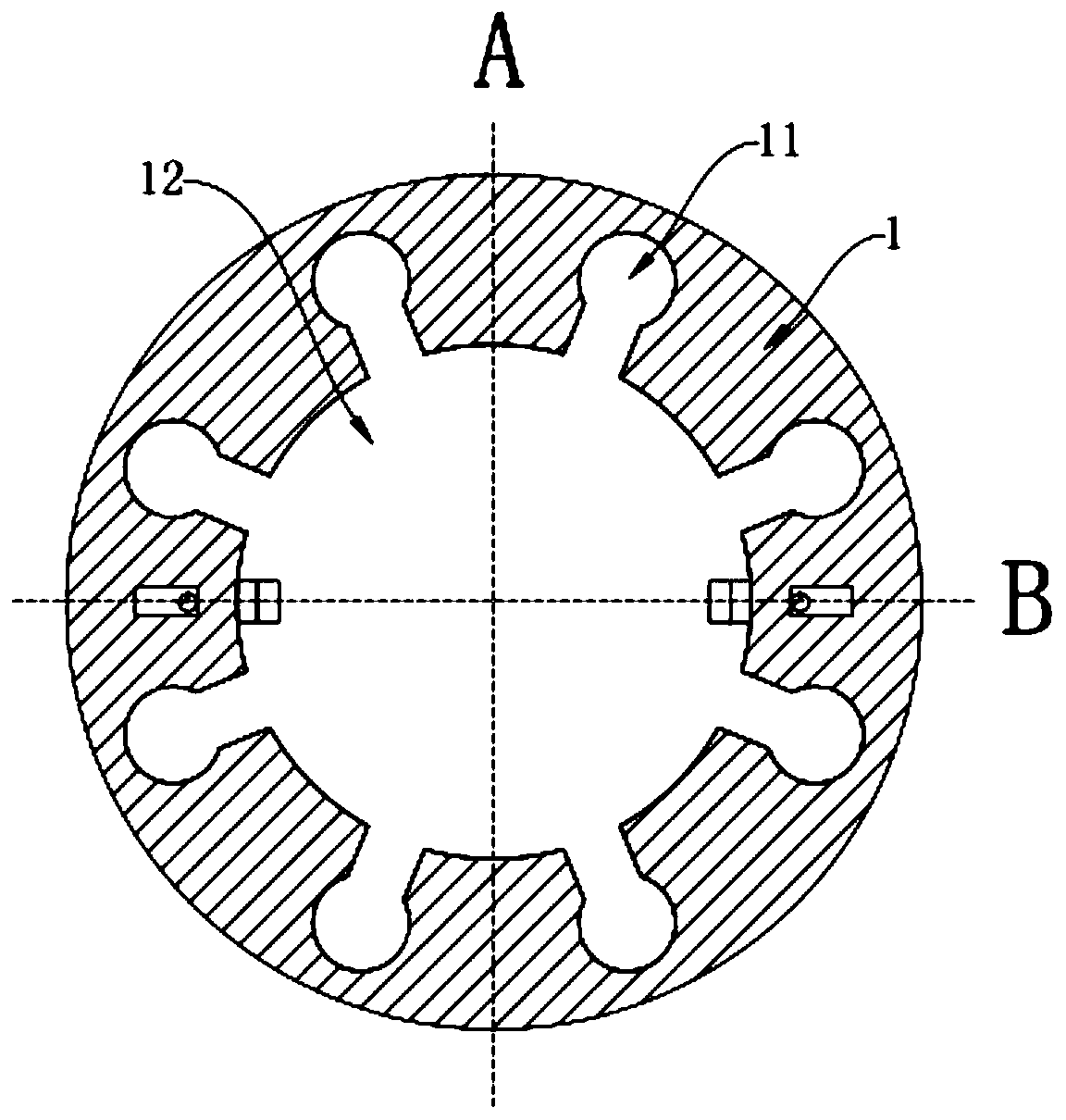

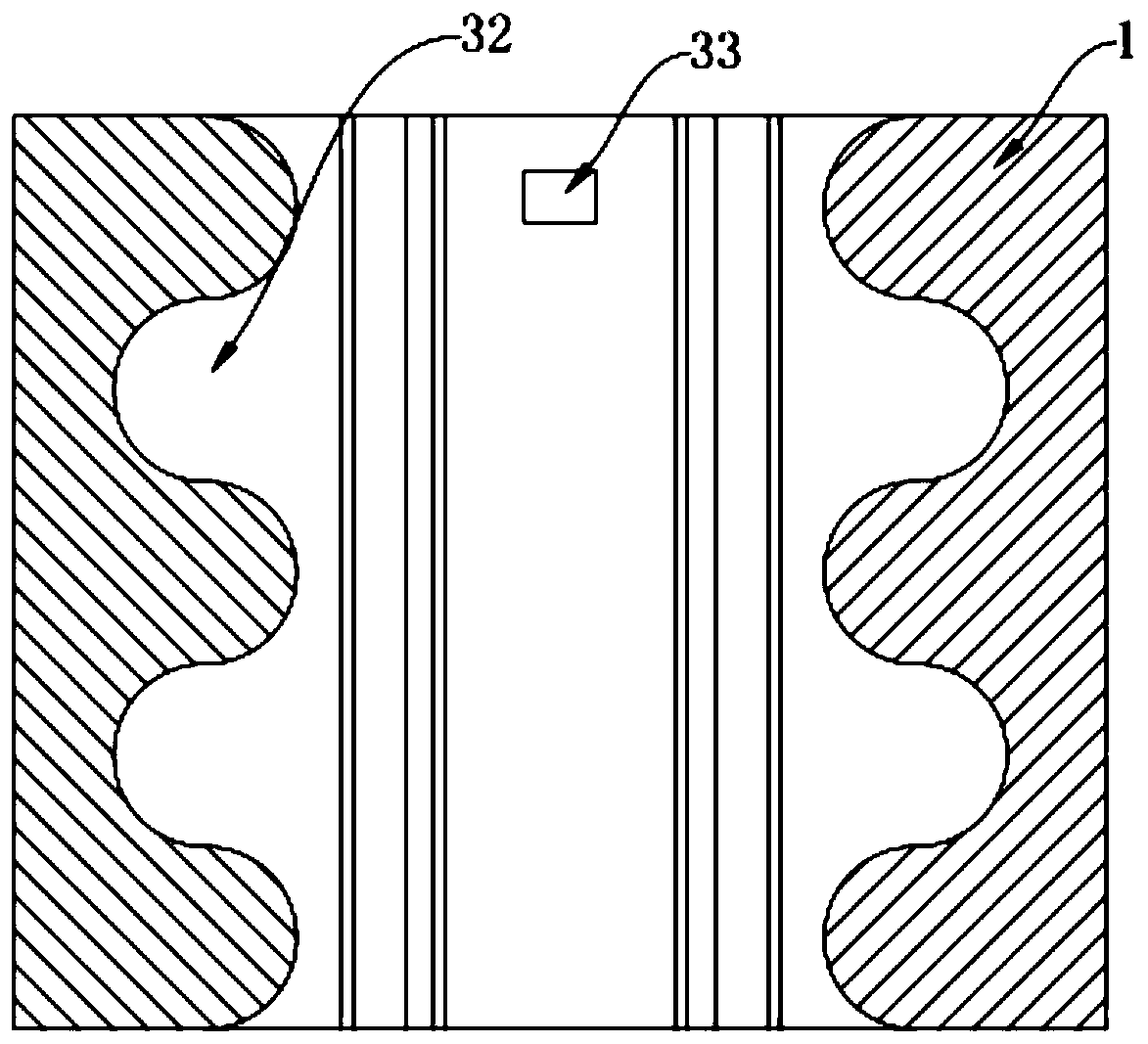

[0030] figure 1 It is a schematic diagram of the overall structure of the present invention, please combine figure 1 , shows a connection structure for the motor output shaft 1 and the rotating shaft 2, including the motor output shaft 1 and the rotating shaft 2, the rotating shaft 2 is embedded in the motor output shaft 1, and can also be the motor output shaft 1 embedded It is arranged in the rotating shaft 2. In this embodiment, preferably, the rotating shaft 2 is embedded in the output shaft 1 of the motor. A plurality of bumps 21 are arranged on the rotating shaft 2, and the bumps 21 are radially distributed along the axis of the rotating shaft 2. The motor output shaft 1 is provided with a circumferential limit groove 11 matche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com