9-axis linkage welding robot with C-shaped cantilever structure

A welding robot and shaft linkage technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of physical hazards of surrounding workers, reduce product use effect, pollute the environment, etc., and achieve good smoke removal effect , Improving the use effect, convenient maintenance and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

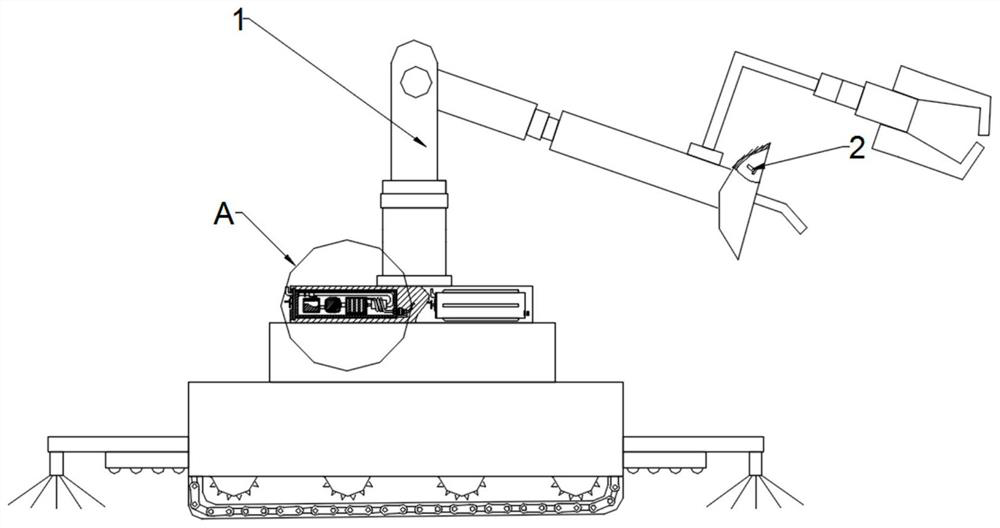

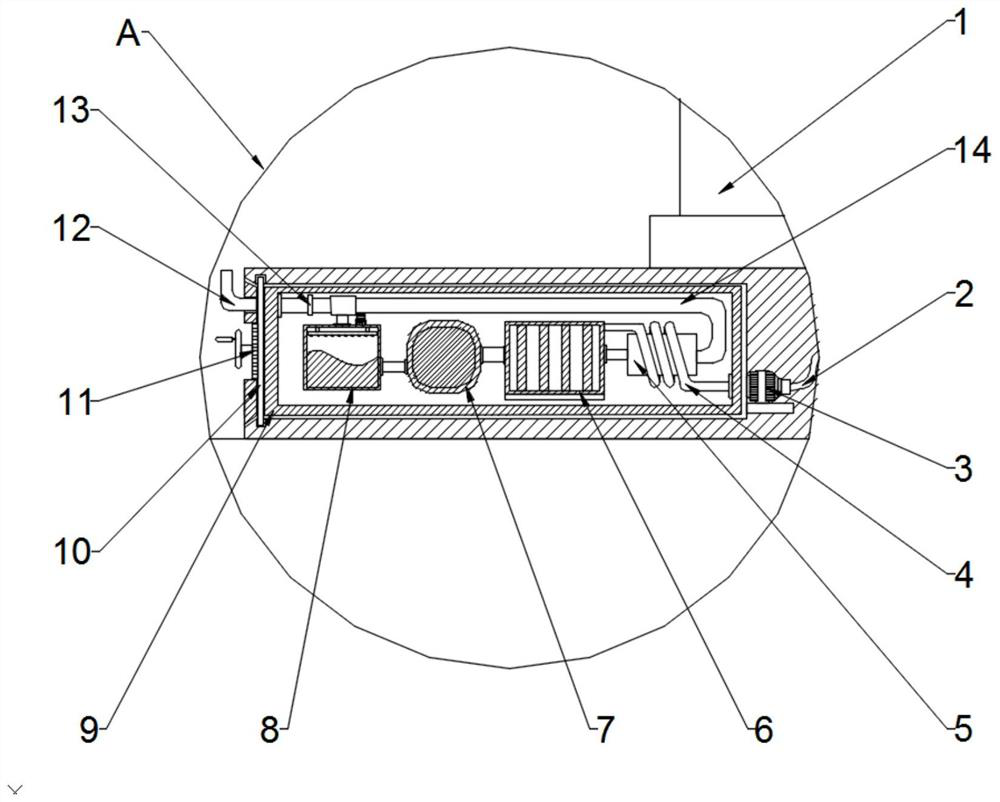

[0042] See figure 1 versus figure 2 A C-type cantilever structure 9 axis linkage welding robot, including welding robot main body 1, and welding robots include:

[0043] The transmission pump 3 is fixed to the outer surface wall of the clear hookes main body 9, and the outer surface of the cleavage body 9 is fixed to the welding robot body 1, and the inner surface wall of the clear hook hood is fixedly connected to the exhaust pipe 12, the exhaust pipe 12 The outer wall fixing the electromagnetic valve 13, the outer surface wall of the solenoid valve 13 is fixedly connected to the circulation tube 14, and the circulation tube 14 is fixedly connected to the dry bin 5, the transmission pump 3 transmission ends are connected to the smoking pipe 2, the transmission pump 3 away from smoking pipe 2 One end is connected to the dry tube 4, the outer surface wall of the drying tube 4 is wrapped with the dry bin 5, and the dry bin 5 is fixed to the pipe opening 6, and the filter dust cart...

Embodiment 2

[0047] See Figure 5 versus Figure 6 The inner surface wall of the clear hook hook hood is engaged with the transmission pump 3 by the elastic ring protrusion, the outer wall of the welding robot body 1 is connected to the door 15 through the rotating shaft activity, the interior wall of the hatch 15 is connected to the screw 16 The inner surface wall of the hatch 15 is attached to the clear hook hook body 9, and the inner surface wall of the hatch 15 is fixedly connected to the elastic gasket, and the gap between the fingertips 15 and the cleavage hoses body 9 makes the connection more tightly. The inner surface wall of the cleavage hood body 9 is fixedly connected to the sealing space of the dry tube 4 and the transmission pump 3 in the inner surface wall of the cleaning tank body 9 and the transmission pump 3.

[0048]Open the hatch 15, pushing the strip projections on the cleavage hood body 9 push along the slot on the inner surface wall of the welding robot, so that the tran...

Embodiment 3

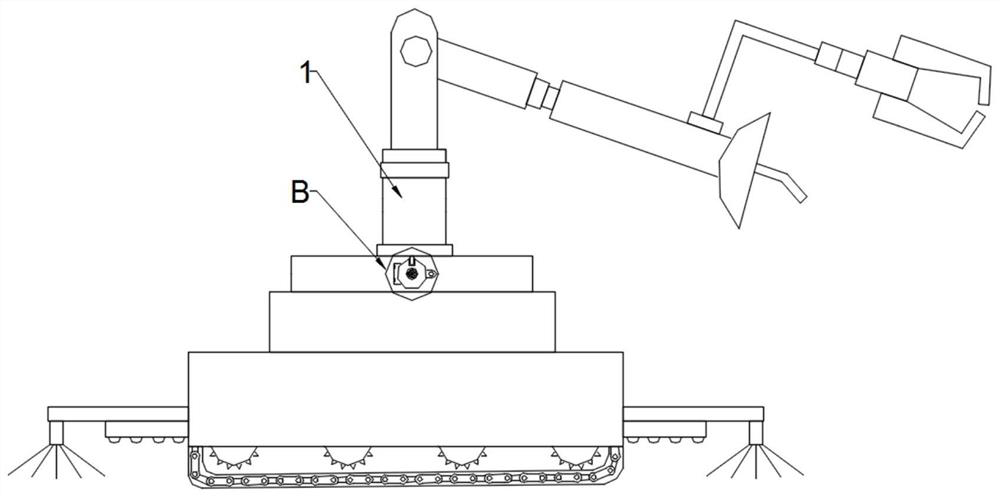

[0051] See figure 2 versus Figure 7 The nichoid body 9 is fixedly connected to the chassis 10, and the chassis 10 is distinguished from the sides of the clear hookami body 9, and the rotating gear 11 is connected, and the inner surface wall slides in the rotation gear 11, the slider 17 is fixedly connected. There is a light rod 18, and the light rod 18 is fixedly connected to the pressure plate 19, and the rotating gear 11 is fixedly connected to the handle, facilitating the operator rotating the gear 11, and engages the pressure plate 19 with the welding robot body 1.

[0052] Turn the handle, drive the rotating gear 11 to rotate, so that the slider 17 is moved along the slide on the inner wall of the rotation gear 11, since the slider 17 is fixed to the light rod 18, the light rod 18 will move along the bottom surface 10 The pressed plate 19 synchronous telescopic and welding robot body 1 is integrated, and the stability of the overall structure connection is improved, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com