Boiler flue gas waste heat recovery system

A technology of waste heat recovery system and boiler flue gas, which is applied in the field of boilers, can solve problems affecting the environment, etc., and achieve the effect of large contact area and good smoke removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

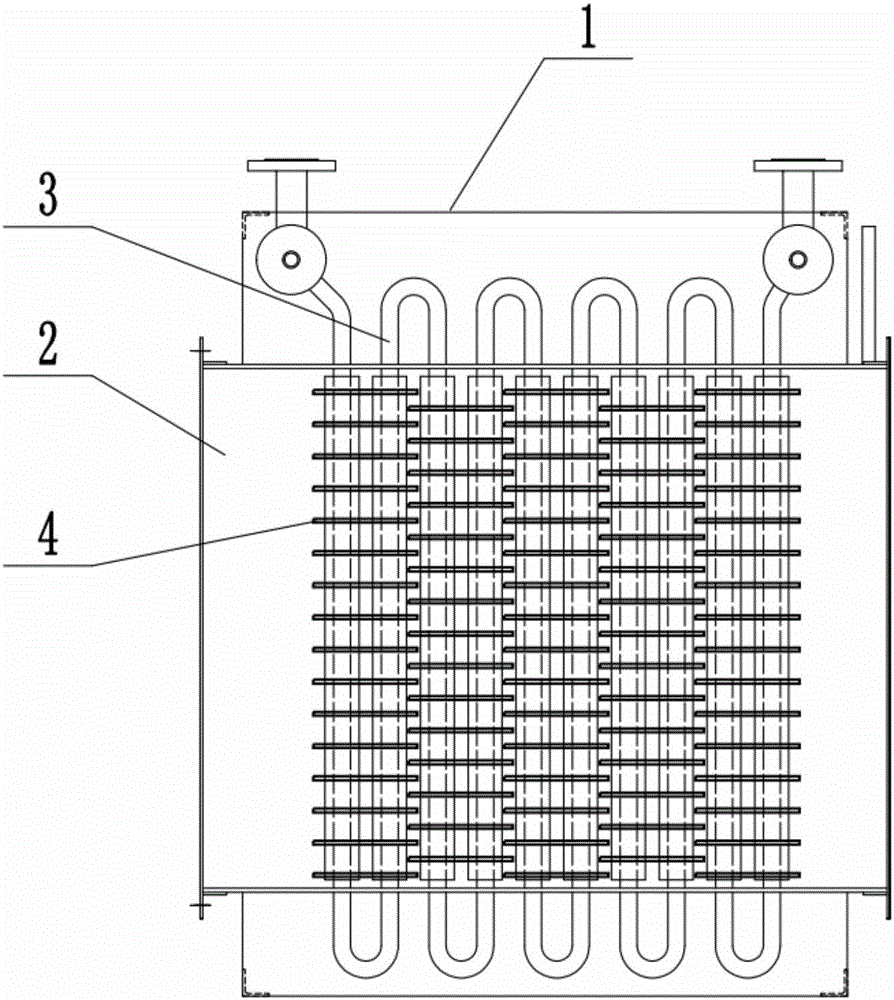

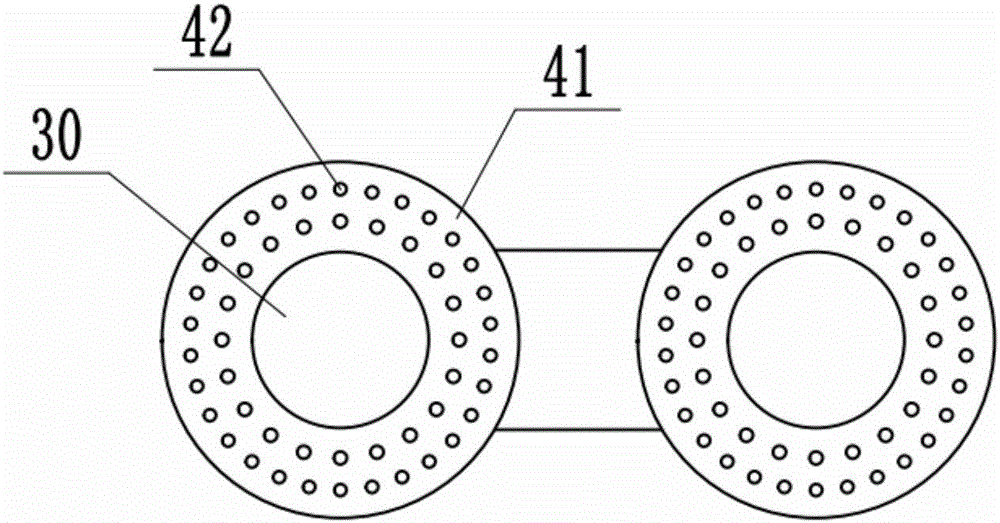

[0011] Such as figure 1 , figure 2 As shown, the boiler flue gas waste heat recovery system of this embodiment includes a flue gas channel 2 installed on a bracket 1, and a serpentine tube 3 placed in the flue gas channel 2 is fixedly installed on the bracket 1, and the serpentine tube 3 A smoke removal sheet 4 is installed between two adjacent vertical sections 30, and a plurality of smoke removal sheets 4 are spaced up and down. The smoke removal sheet 4 includes two smoke removal collars 41 set on the vertical section 30, Filter holes 42 are provided on the smoke removal collar 41 .

[0012] In the present invention, smoke removal sheets 4 are separately arranged on the serpentine pipe 3, and the smoke removal sheets 4 bind the adjacent vertical sections 30 of the serpentine pipe 3 together, and set filter holes, so that the whole cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com