Fast smoke removing device

A smoke and fast technology, which is applied in the fields of combination device, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of difficult cleaning, poor smoke removal effect, slow suction speed, etc., and achieves convenient device cleaning and fast suction speed. , the effect of clean air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

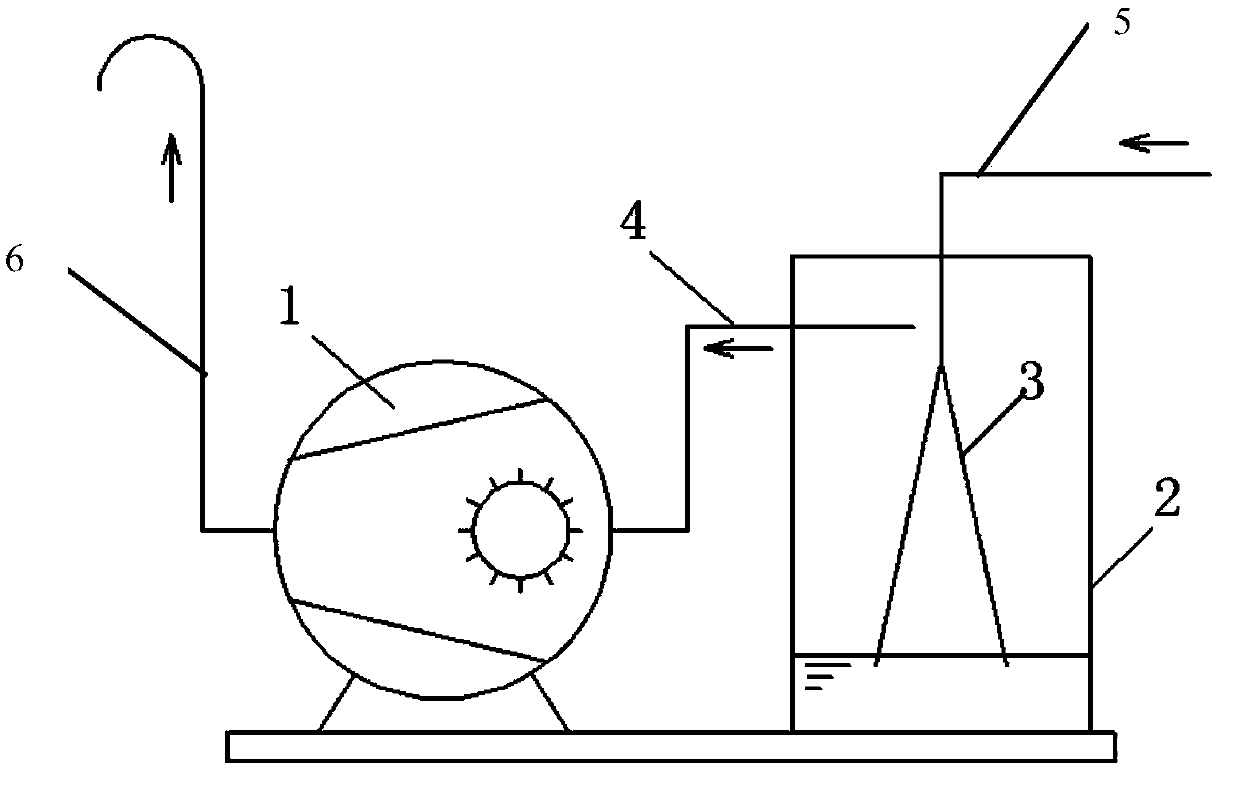

[0026] Please check figure 1 , a quick smoke removal device, including a storage tank 2, an air inlet pipe 5, an exhaust pipe 4, a liquid ring vacuum pump 1 and a chimney pipe 6.

[0027] The storage tank 2 has a circular bottom wall, a rotary peripheral wall extending upward from the periphery of the circular bottom wall, and a sealing cover connected to the upper port of the rotary peripheral wall. The sealing cover is provided with a through hole penetrating up and down. In this embodiment, the revolving peripheral wall is, for example, a cylindrical wall. The rotary peripheral wall is provided with a through opening through which the inside and outside penetrate. The storage tank is filled with liquid, and the liquid level is spaced from the sealing cover. The height of the through opening is higher than the liquid level.

[0028] The air intake pipe 5, the first end is connected to the suction point, such as the suction point connected to the smog workshop, or the suctio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com