Method for improving air purifier insulation

An air purifier and insulating board technology, which is applied to chemical instruments and methods, membrane filters, gas treatment, etc., can solve the problems of air purification devices losing air purification, poor air purification effect, and greatly reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

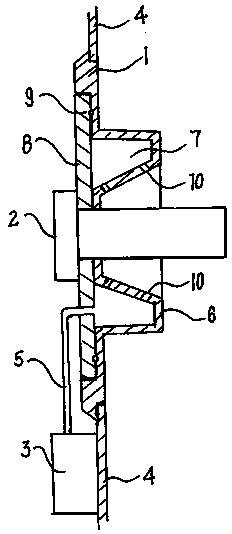

[0018] exist figure 1 In the above, the insulating plate 1 replaces the shell metal plate near the porcelain joint installed in the shell, and is used for the insulation between the emitter and the collector; the porcelain joint 2 is fixed on the insulating plate to avoid the leakage of the porcelain joint and lead Through the injector electrode and the collector electrode; the air pump or liquid pump 3 is installed on the outside of the housing 4 of the machine body, and connected to the spray plate 6 with a pipeline 5, which is used to supply pressure gas or provide pressure liquid to the spray plate, and the spray unit The injection disc 6 is arranged near the ceramic joint 2, the annular air channel 7 is pressed on the insulating plate 1, integrated with the insulating plate, and protrudes into the box, and the center hole is opened in the middle of the annular air channel; The cover plate 8 is independently pressed, the diameter of the cover plate is greater than the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com