Juicer with reliable structure

A juicer, a reliable technology, applied in the field of food processing machines, can solve the problems of large space occupied by the upper cover, concentrated stress on the upper cover, and influence on service life, etc., and achieve the effect of improving feeding efficiency, increasing speed, and facilitating cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

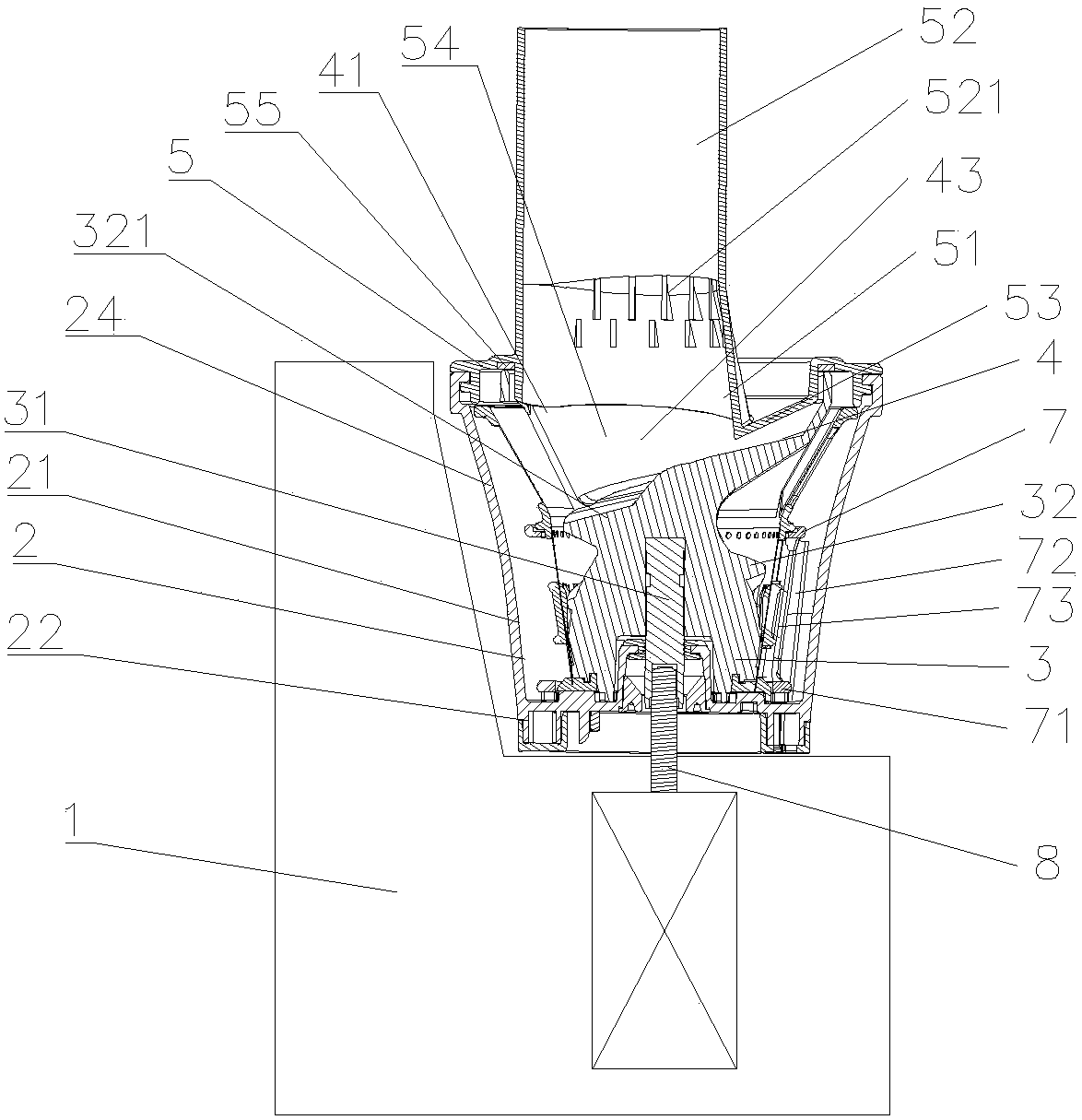

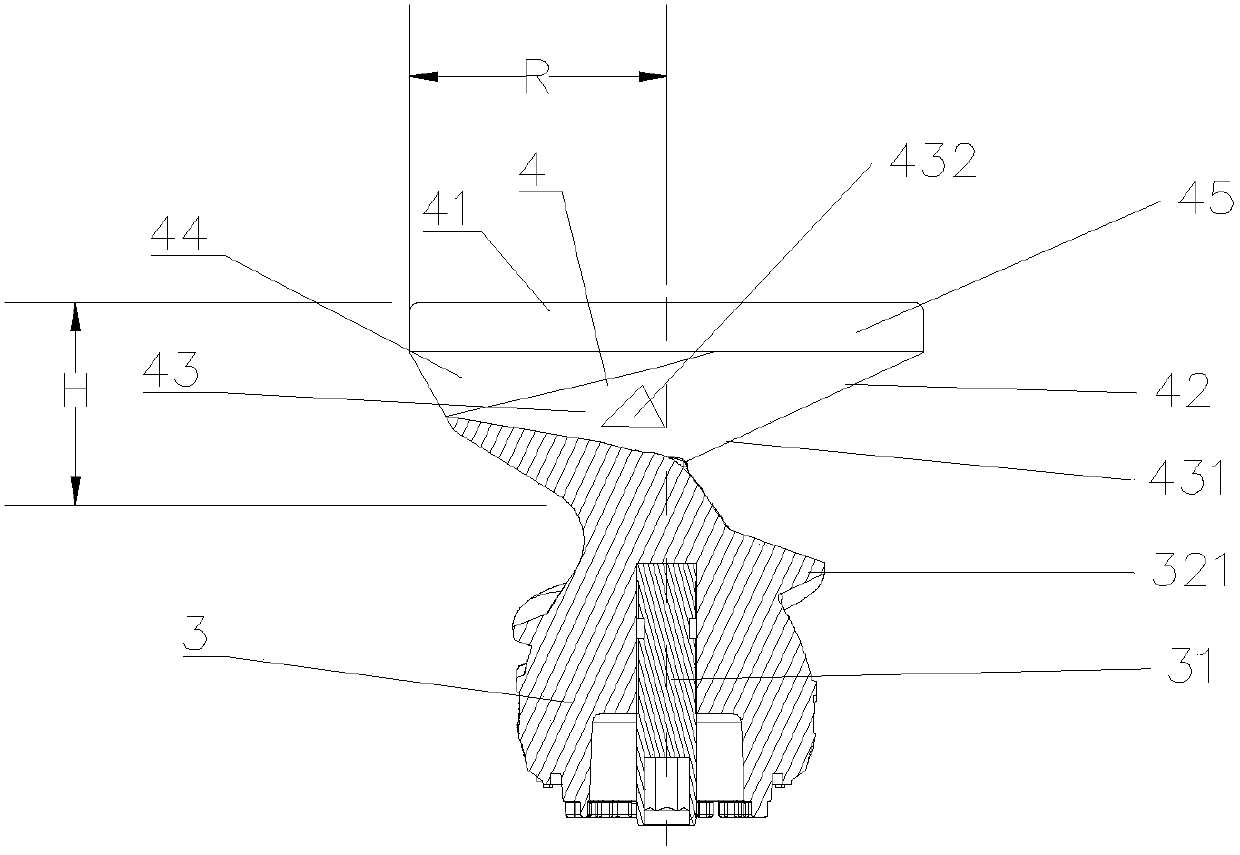

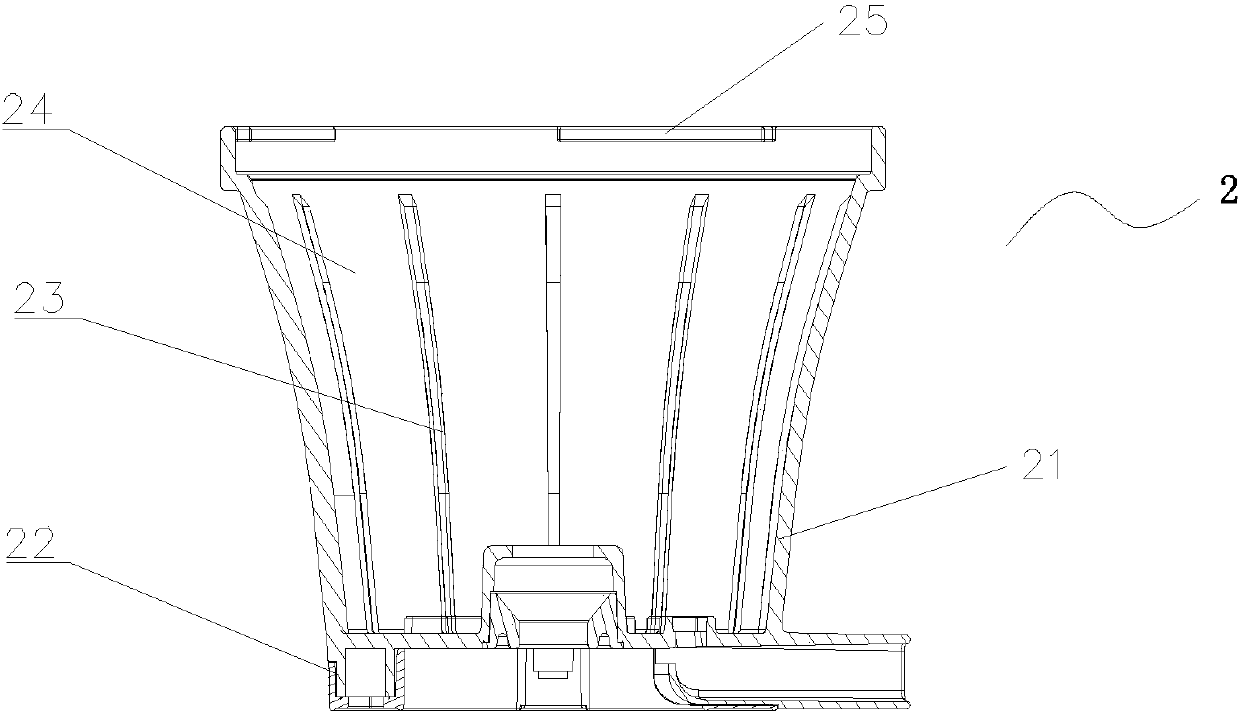

[0053] Such as Figure 1 to Figure 5 As shown, a juice extractor with a reliable structure includes a machine base 1, a juice collection container 2 arranged above the machine base 1, an extrusion screw 3 longitudinally arranged in the juice collection container 2, and a cover on the juice collection container 2 The loam cake 5 at the upper end, the end face of the loam cake 5 is provided with an opening 51 and a feed channel 52 communicating with the opening, the extruding screw 3 includes a body and a screw shaft 31, the body is provided with a screw 32, The upper end of the extruding screw 3 is provided with a rotary feeder 4, the rotary feeder 4 includes a feed port 41 and a discharge port 42, and the opening 51 corresponds to the feed port 41 of the rotary feeder set, and the opening 51 covers the rotation center of the extruding screw, the discharge port 42 communicates with the juice collection container 2, and the extruding screw 3 drives the rotary feeding device 4 to...

Embodiment 2

[0091] Such as Figure 6 to Figure 11 As shown, the difference between this embodiment and Embodiment 1 is that a squeeze filter cartridge 6 is also provided in the juice collection container, and the squeeze screw is sleeved in the squeeze filter cartridge 6, and the squeeze filter cartridge includes a barrel body and a filter screen fitted on the cylinder, filter holes are arranged on the filter screen, and an extrusion cavity is formed between the extrusion screw 3 and the extrusion filter cylinder 6. The material enters through the feeding port 41 of the rotary feeding device 4 , rotates with the rotary feeding device and is output from the discharge port 42 , enters the extrusion cavity, and is driven by the extrusion screw 32 to move downward for crushing and extrusion. The squeeze filter cartridge 6 divides the space formed by the squeeze screw 3 and the juice collection container 2 into two chambers, the squeeze cavity formed between the squeeze screw 3 and the inner w...

Embodiment 3

[0106] Such as Figure 12As shown, the difference between this embodiment and Embodiment 1 is that the equivalent diameter of the opening 51 is greater than the rotation diameter of the rotary feeding device 4, a is 4 / 3, and the equivalent diameter of the opening is 120 mm. The rotary diameter of the rotary feeding device is 90mm, the opening completely covers the feeding port 41, and the lower end of the inner wall of the feeding channel is provided with an annular limiting boss 522, and the limiting structure is the convex Platform 522, the feeding port of the rotary feeding device 4 is sleeved on the inner ring surface of the lower end of the feeding channel 52 through the positioning ring 45, the upper end surface of the positioning ring 45 abuts against the lower end surface of the boss, and the rotating The feed device 4 is axially limited, and the inner ring surface at the lower end of the feed channel 52 cooperates with the outer ring surface of the positioning ring 45...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com