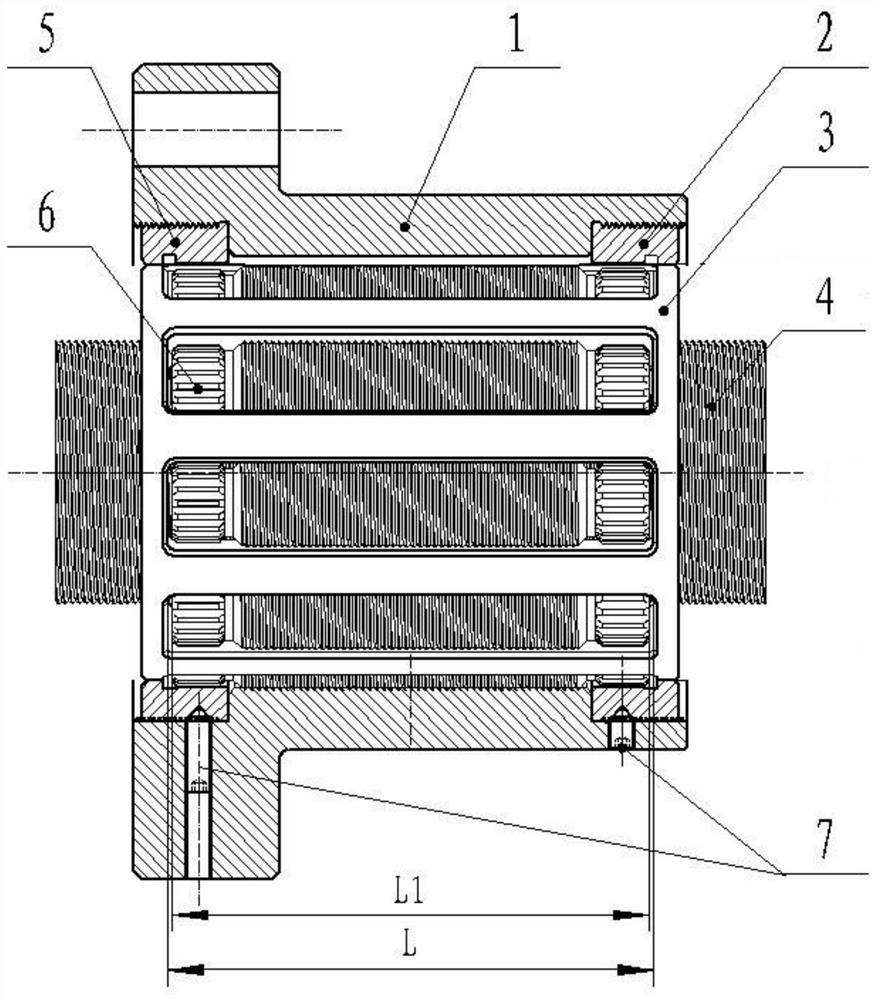

Planetary roller lead-screw pair

A technology of planetary rollers and lead screw pairs, which is applied in the direction of belts/chains/gears, mechanical equipment, transmission devices, etc., can solve problems such as the inability to limit the inclination of rollers with high precision, achieve simple structure, strong load-bearing capacity, and improve load-carrying effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further elaborated below in conjunction with embodiment.

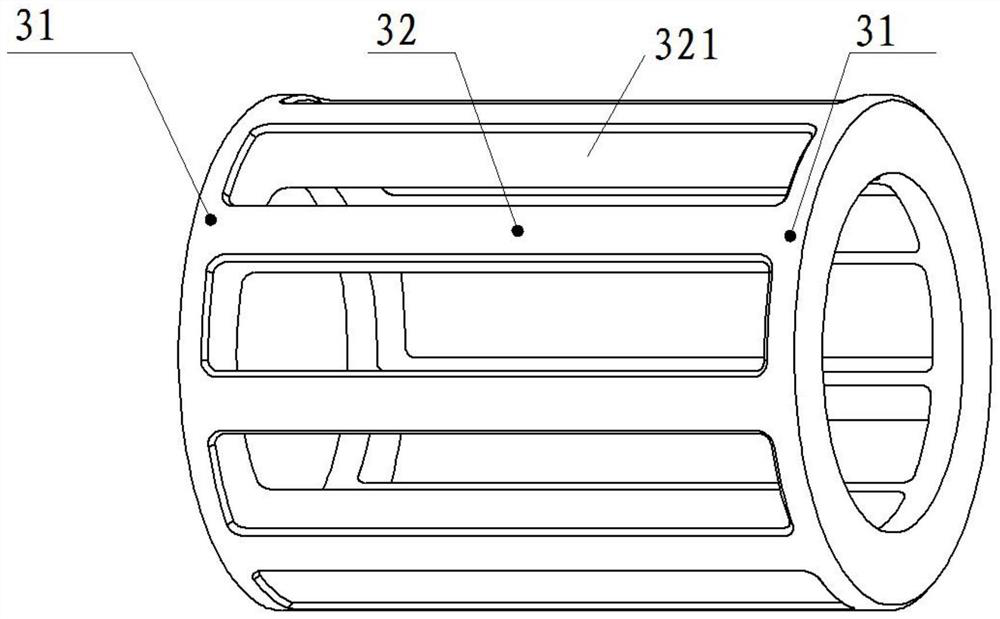

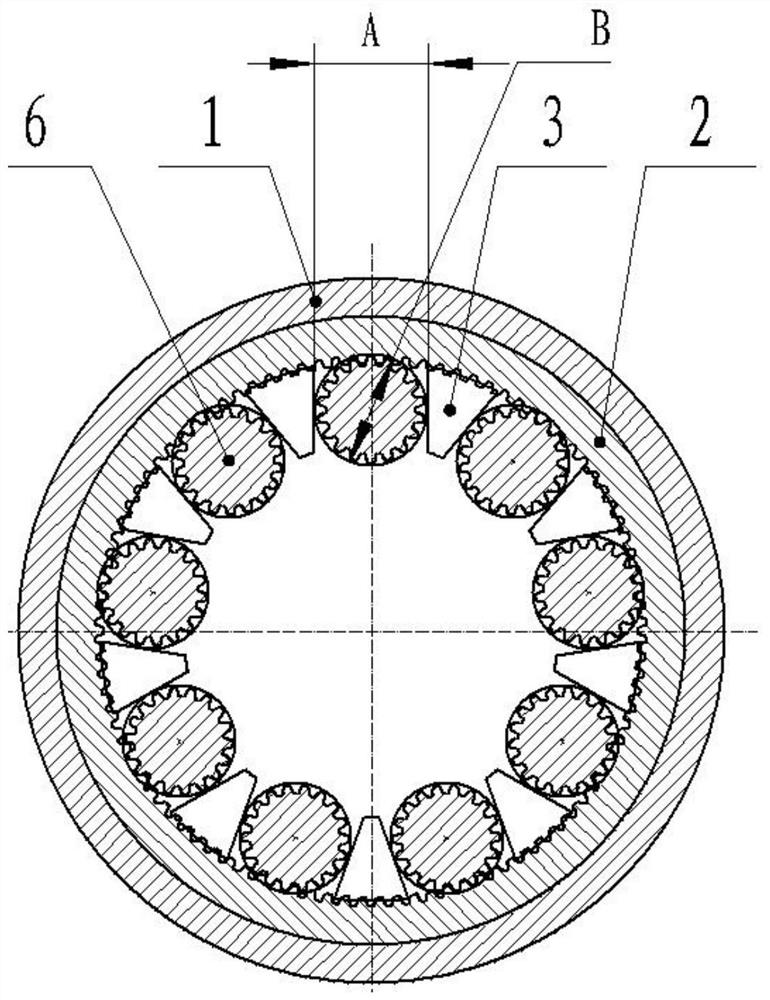

[0023] The invention proposes an integral cage planetary roller screw pair, which has the characteristics of simple structure, high precision, strong bearing capacity, and stable movement, and solves the problem that the split cage cannot limit the inclination of the rollers with high precision. problem, making the transmission of the screw pair more stable; at the same time, the axial limit structure of the original cage is omitted, which makes the thread load length longer under the same conditions and improves the bearing capacity of the screw pair.

[0024] In order to prevent the rollers of the planetary roller screw from inclining relative to the screw and improve the stability of the planetary motion of the rollers, a novel planetary cage structure of the planetary roller screw is designed in the present invention. It can improve the stability, precision and bearing capacity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com