Shaft transmission tricycle capable of swinging

A tricycle and shaft transmission technology, applied in the direction of motor vehicles, rotary transmission devices, bicycles, etc., can solve the problems of complex assembly process, poor reliability and low assembly efficiency, and achieve the effect of ensuring transmission performance, high reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

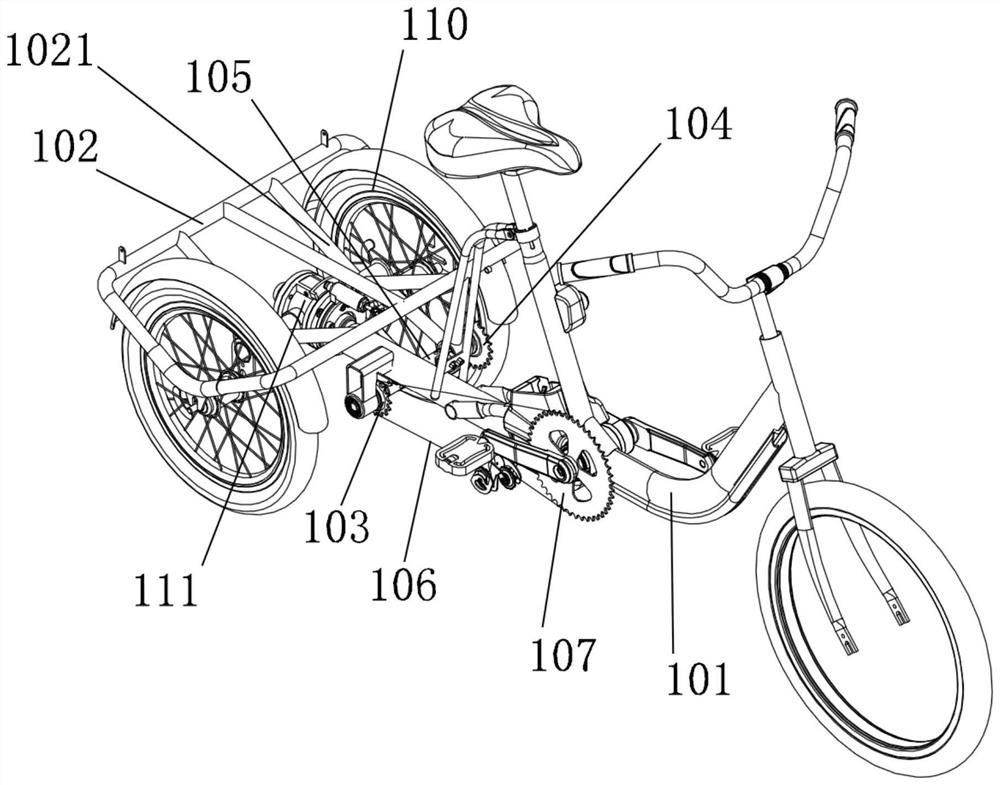

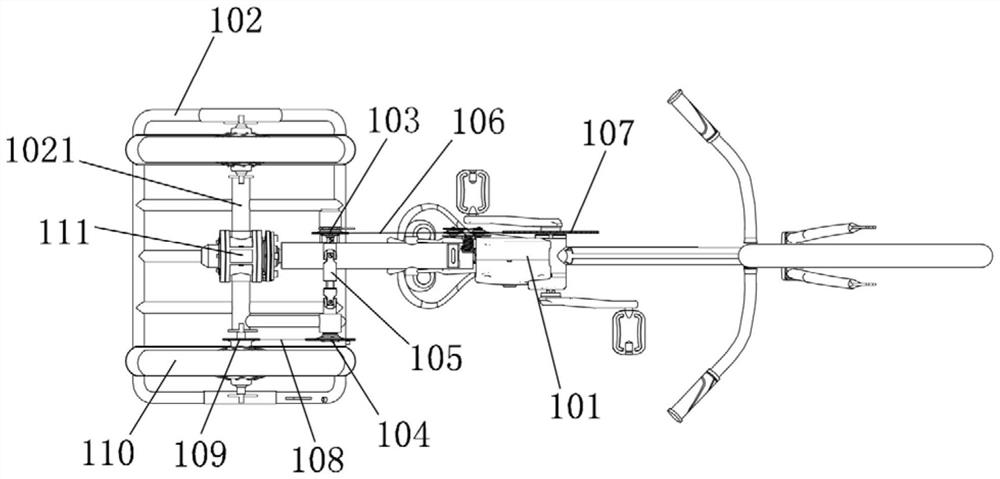

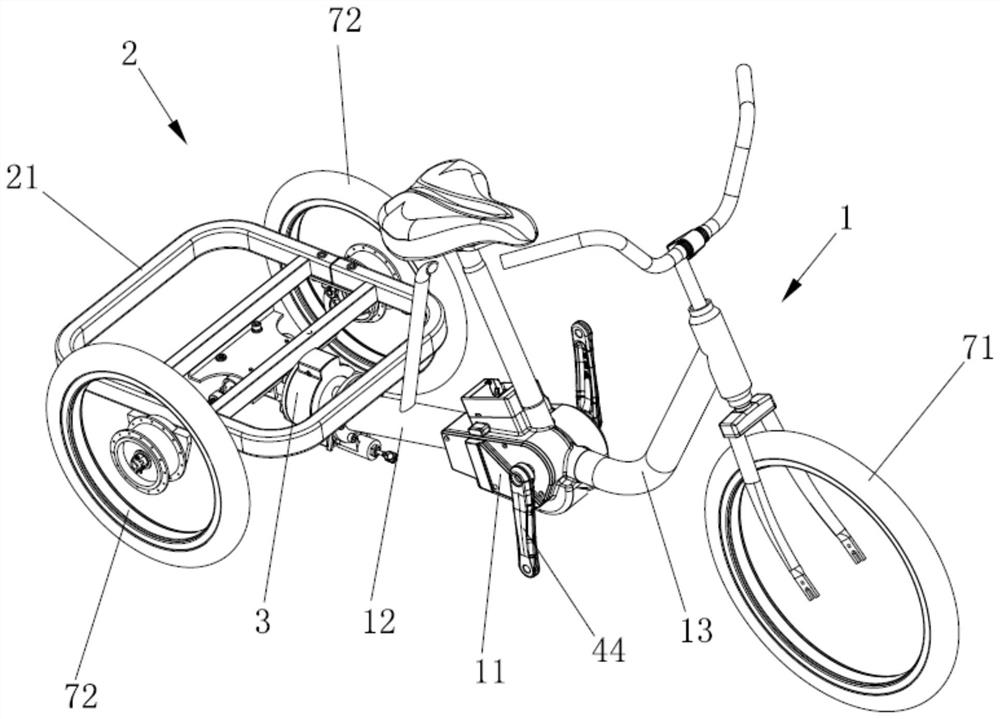

[0049] see Figure 3 to Figure 15 According to the embodiment of the swingable shaft drive tricycle provided by the invention, it comprises a front frame 1, a rear frame 2 and a transmission mechanism, and the front frame 1 is provided with a front wheel 71 (the front wheel in the accompanying drawing is a structural schematic diagram ), two rear wheels 72 are symmetrically arranged on the rear frame 2 (the rear wheels in the accompanying drawings are structural schematic diagrams), and the front frame 1 is swingably connected with the rear frame 2 through a swing mechanism 3 , the transmission mechanism includes a first torque output assembly 4 arranged on the front frame 1, a second torque output assembly 5 arranged on the rear frame 2, and the first torque output assembly 4 passes through the transmission The shaft 6 transmits the torque to the second torque output assembly 5; the second torque output assembly 5 cooperates with at least one of the two rear wheels 72; the mi...

Embodiment 2

[0065] The structure of this embodiment is substantially the same as that of the above-mentioned first embodiment, only the structure of the first torque output assembly is different. Cranks 44 at both ends of the central shaft 41 , the central shaft 41 drives the transmission shaft 6 through the first gear pair. The first torque output assembly 4 has a simple structure, few parts and convenient assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com