Novel gear and gear rack drive mechanism used for rope twisting knotting machine

A technology of rack and pinion and transmission mechanism, which is applied in knotting, textile and papermaking, etc., can solve the problems of high production cost, affecting the knotting effect, unable to achieve the knot spacing, etc., and achieves the effect of simple structure and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

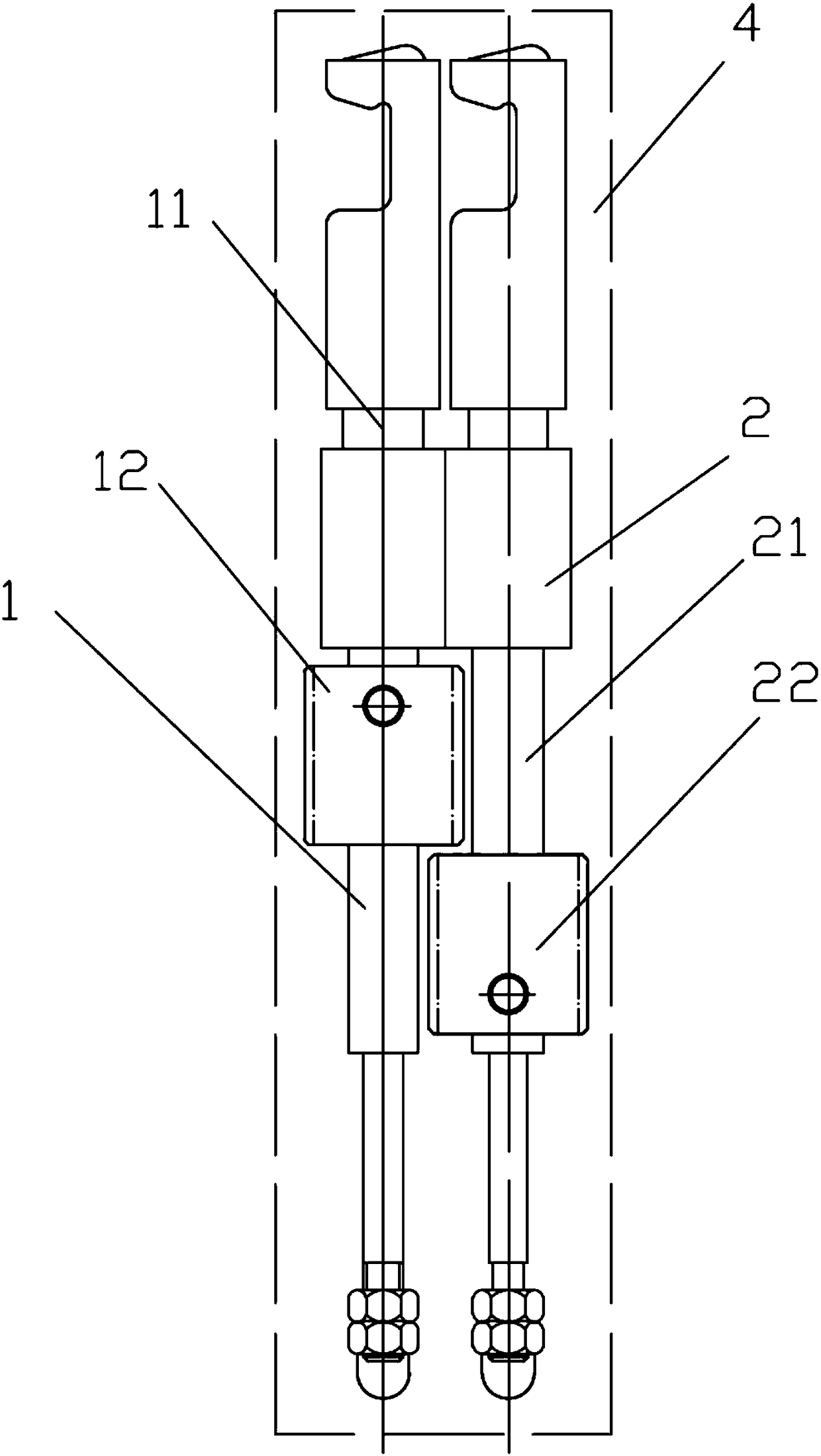

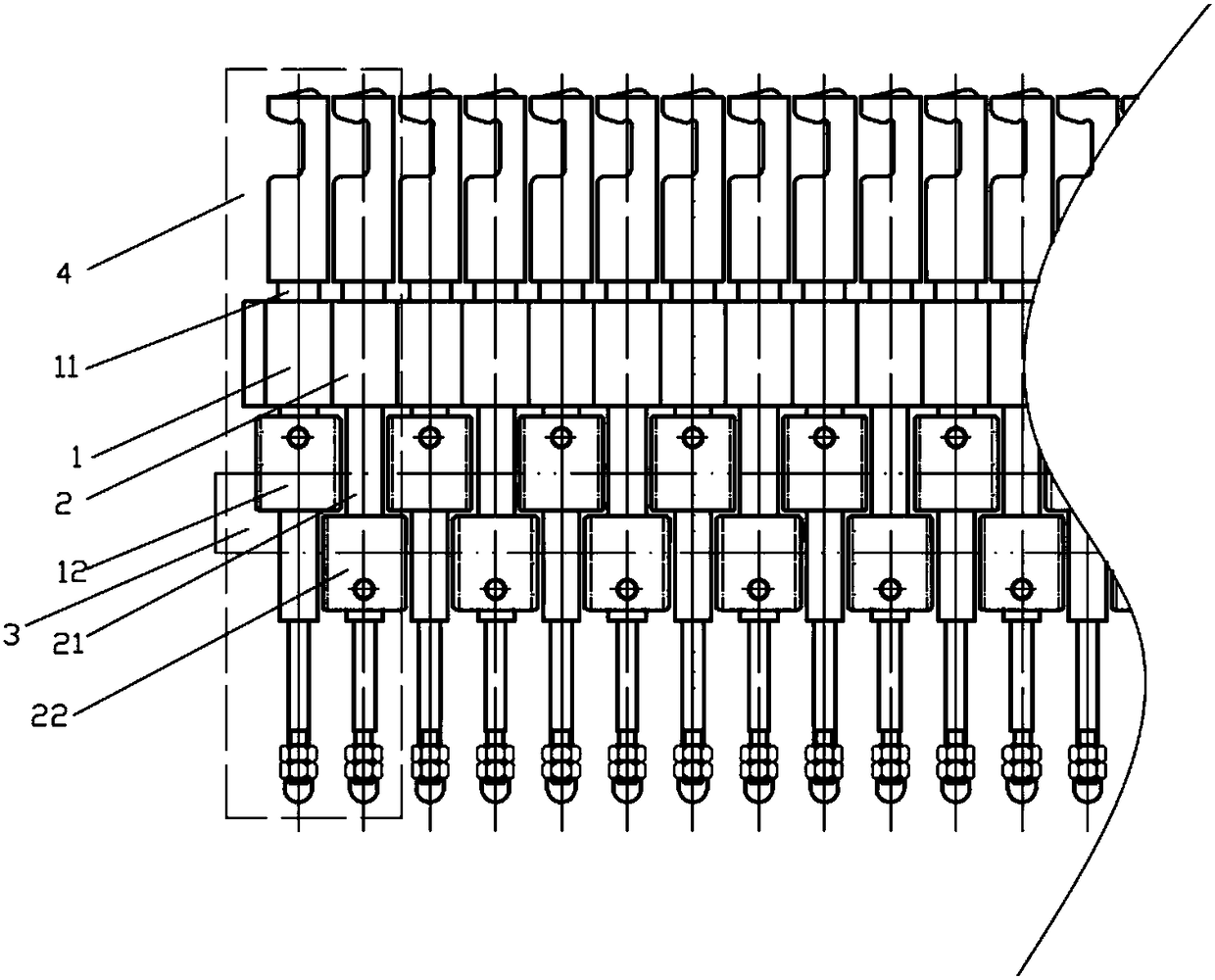

[0011] As shown in the figure, a new type of rack and pinion transmission mechanism for a rope knotting machine includes a knotting claw one 1, a knotting claw two 2 and a rack 3, and the knotting claw one 1 includes a claw rod one 11 and gear one 12, said gear one 12 is located on the claw lever one 11, said knotting claw two 2 comprises claw lever two 21 and gear two 22, and said gear two 22 is also located on the claw lever two 21, The level of the first gear 12 is higher than that of the second gear 22, and part of the second gear 22 is accommodated in the gap between the first gear 12 and the claw rod one 11. The first knotting claw 1 and the second knotting claw 2 constitute a knotting unit 4, the number of the knotting units 4 is several, and the rack 3 meshes with the gear one 12 and the gear two 22 in each knotting unit 4; the width d1 of the gear one 12 and the width d1 of the gear two The width d2 of 22 is the same; the width d3 of the rack 3 is the same as the widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com