Hydraulic motor cylinder block oil distribution disc assembly and machining method thereof

A processing method and technology of hydraulic motor, applied in servo motor components, fluid pressure actuating devices, mechanical equipment, etc., can solve the problems of small equipment clearance, damaged assembly parts, large assembly clearance, etc., to ensure the transmission performance and prolong the use. The effect of high life and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] All the features disclosed in this specification, except mutually exclusive features and / or steps, can be combined in any way.

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings.

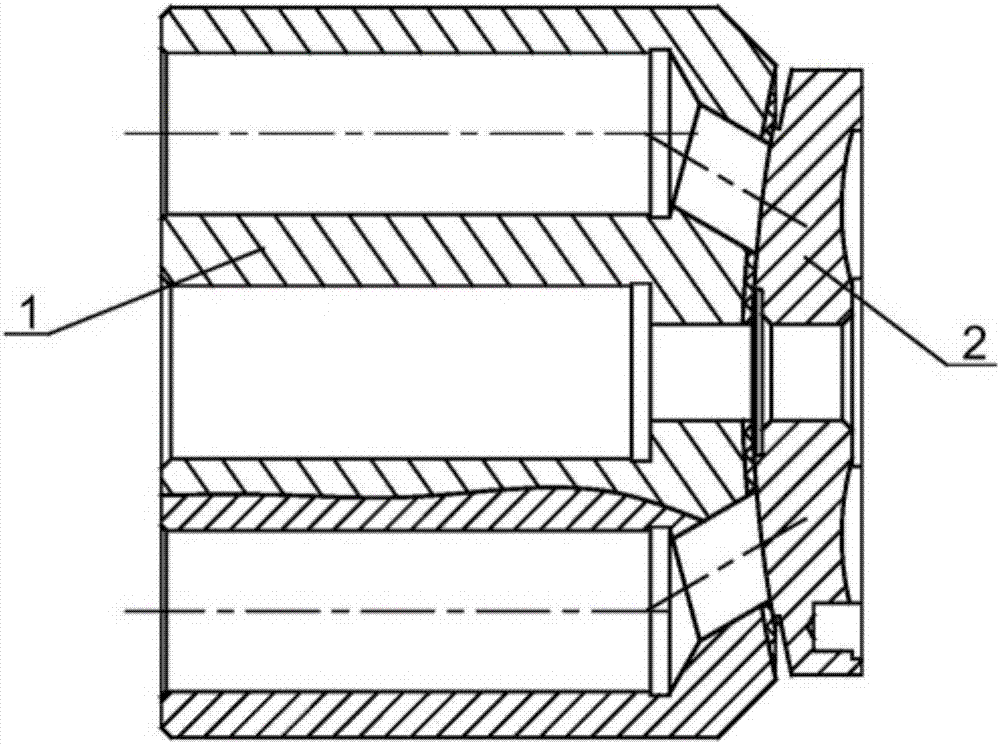

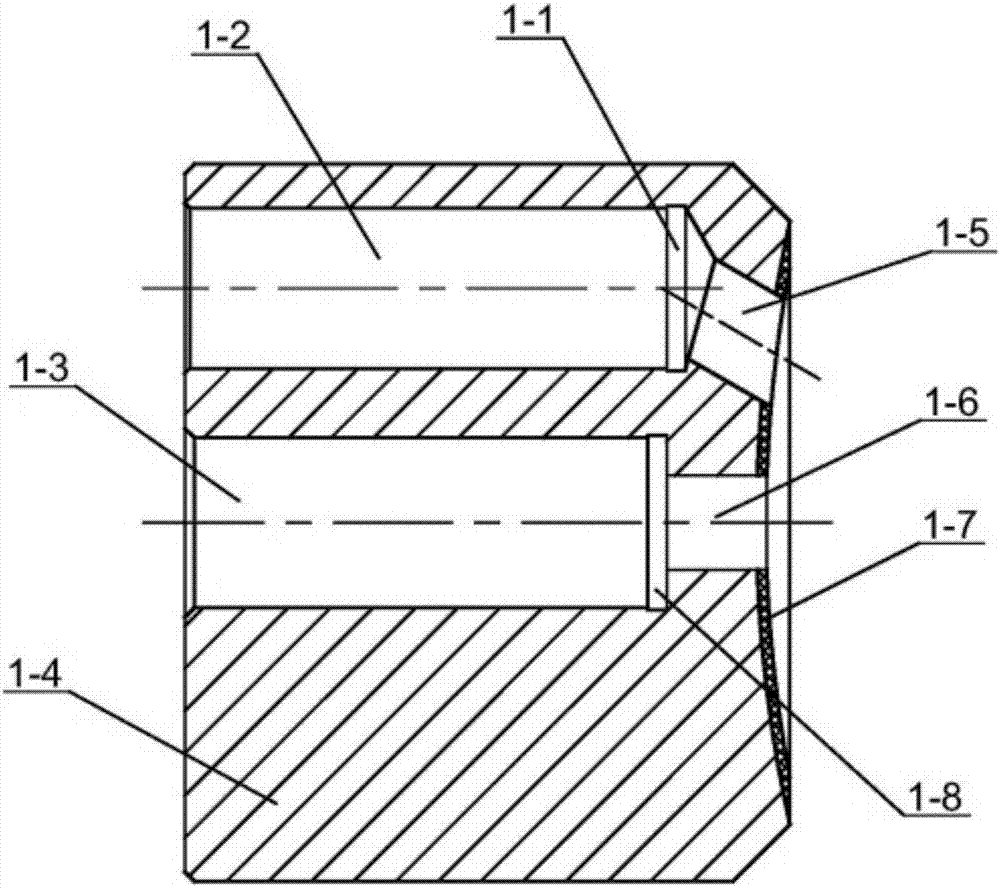

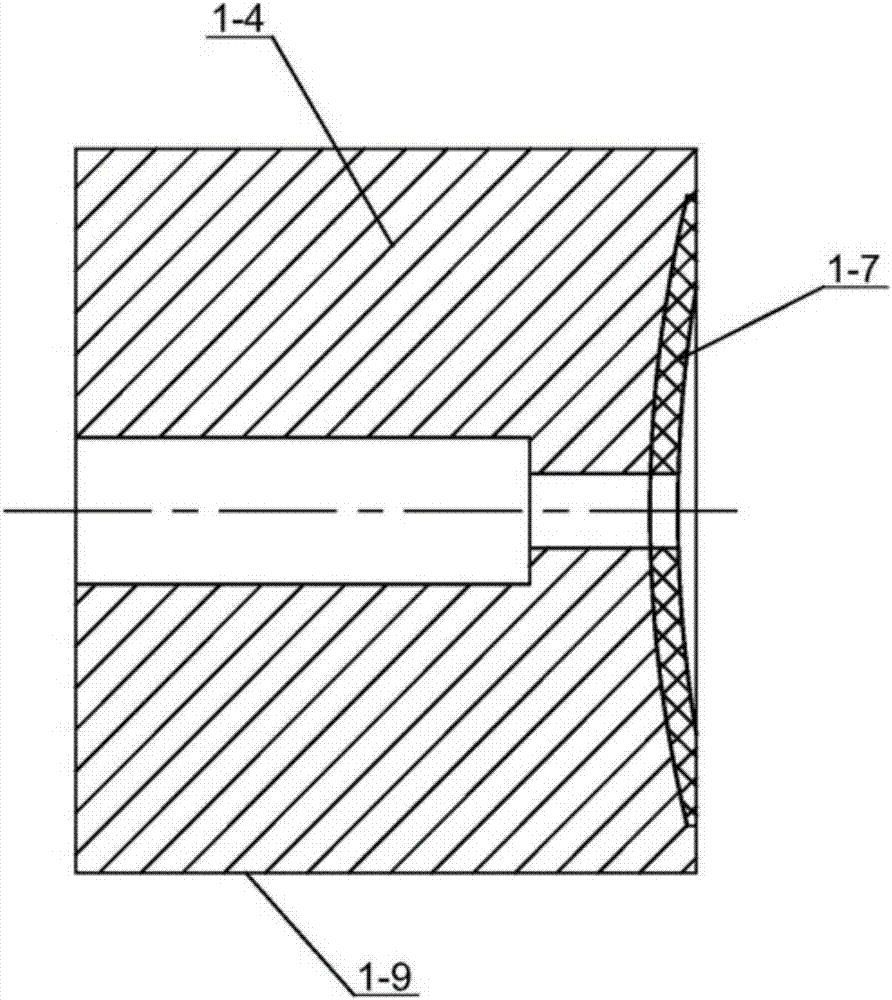

[0044] see Figure 1 to Figure 9 A hydraulic motor cylinder oil distribution plate assembly, including a plunger cylinder 1, a plunger chamber process groove 1-1, a plunger chamber 1-2, a connecting rod chamber 1-3, and a cylinder body 1- 4. Cylinder body oil circuit 1-5, cylinder body flushing oil circuit 1-6, sintered copper 1-7, connecting rod cavity process tank 1-8, cylinder outer circle 1-9, oil distribution plate 2, vibration reduction Groove, oil discharge channel 2-2, oil distribution plate flushing oil circuit 2-3, oil distribution plate processing sink groove 2-4, oil distribution plate positioning pin hole 2-5, oil distribution plate installation positioning sink groove 2-6 , The left process cone surface 2-7 of the oil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| Cylindricity | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com