Tiny component assembling device and method

A technology of tiny parts and assembly devices, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of small parts clamping, positioning limitations, inability to achieve a variety of small parts adsorption, handling and assembly, etc. The effect of ensuring assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

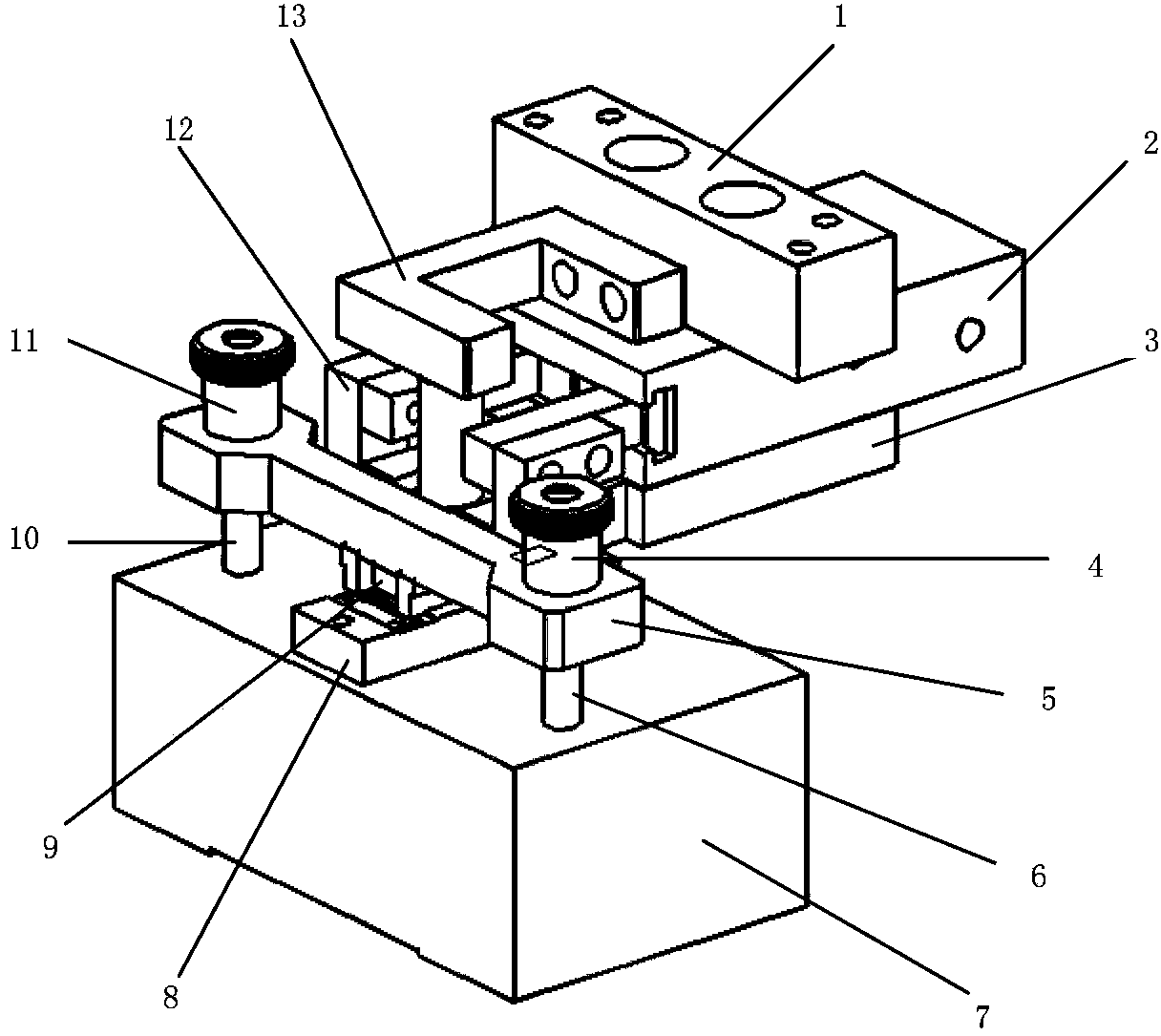

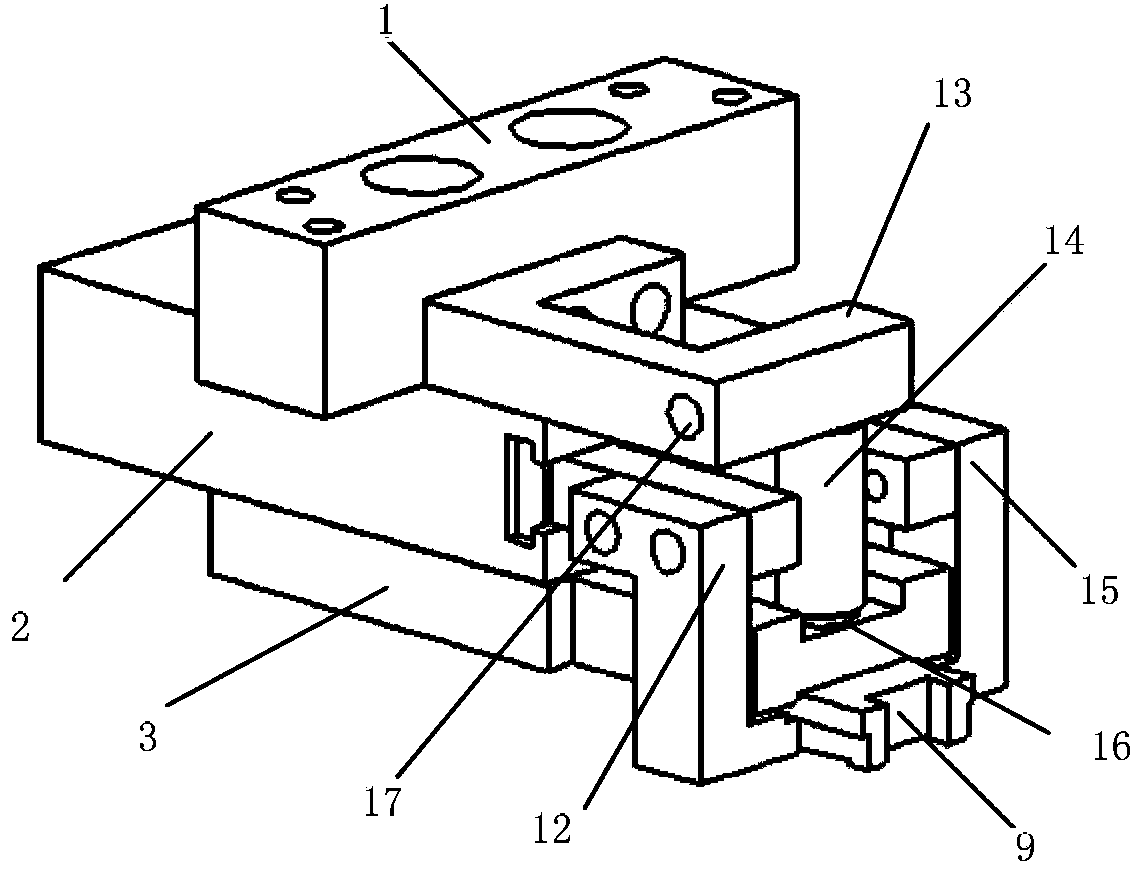

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

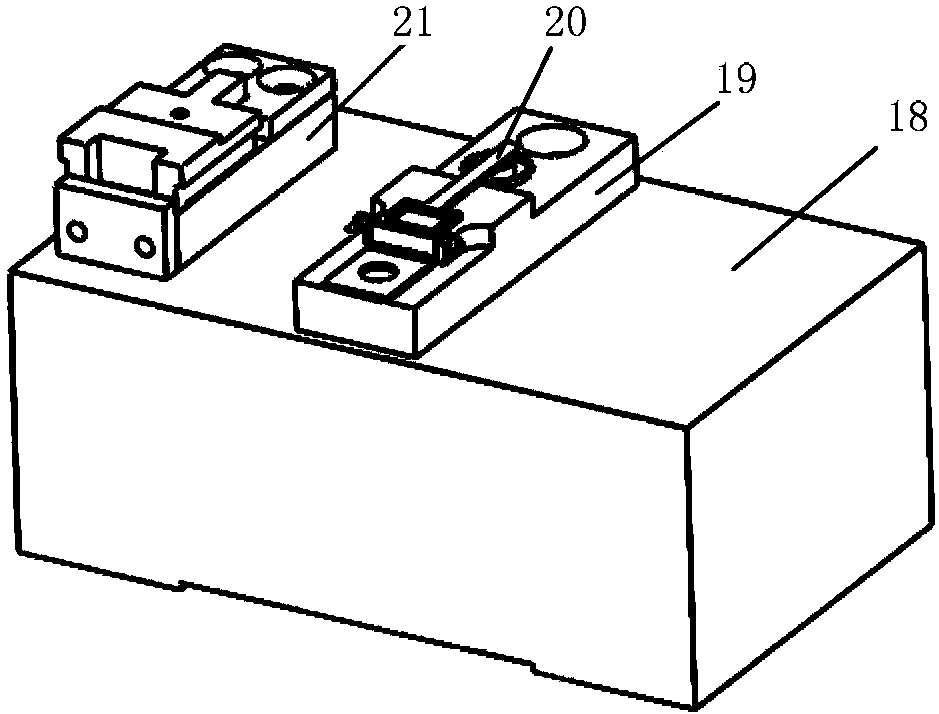

[0021] Step 1: The combined suction clamp unit is fixed on the moving mechanical arm through the connecting block 1. Select the corresponding transitional adsorption block 9 according to the external structure size of the tiny parts 20 to be assembled. The transitional adsorption block 9 is first fixed on the transitional adsorption block feeding base 21, the tiny parts 20 to be assembled are fixed on the parts feeding base 19, and the fixed transitional adsorption block feeding base 21 and the parts feeding base 19 are fixed together on the On the feeding fixture base 18, such as Figure 4 shown.

[0022] Step 2: The combined adsorption clamp unit moves to the specified position, the solenoid valve controlling the power gas of the pneumatic clamp is opened, and the pneumatic clamp 2 starts to move, and is clamped by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com