FPC cam pin inserting machine

A technology of pin insertion machine and cam, which is applied in the assembly/disassembly of contact parts, etc., can solve the problems that the pin length of the product cannot be well maintained, the production efficiency of the cylinder pin structure is low, and the hardware tolerance is not high. Achieve the effect of reducing production scrap rate, omitting reprocessing, and high yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

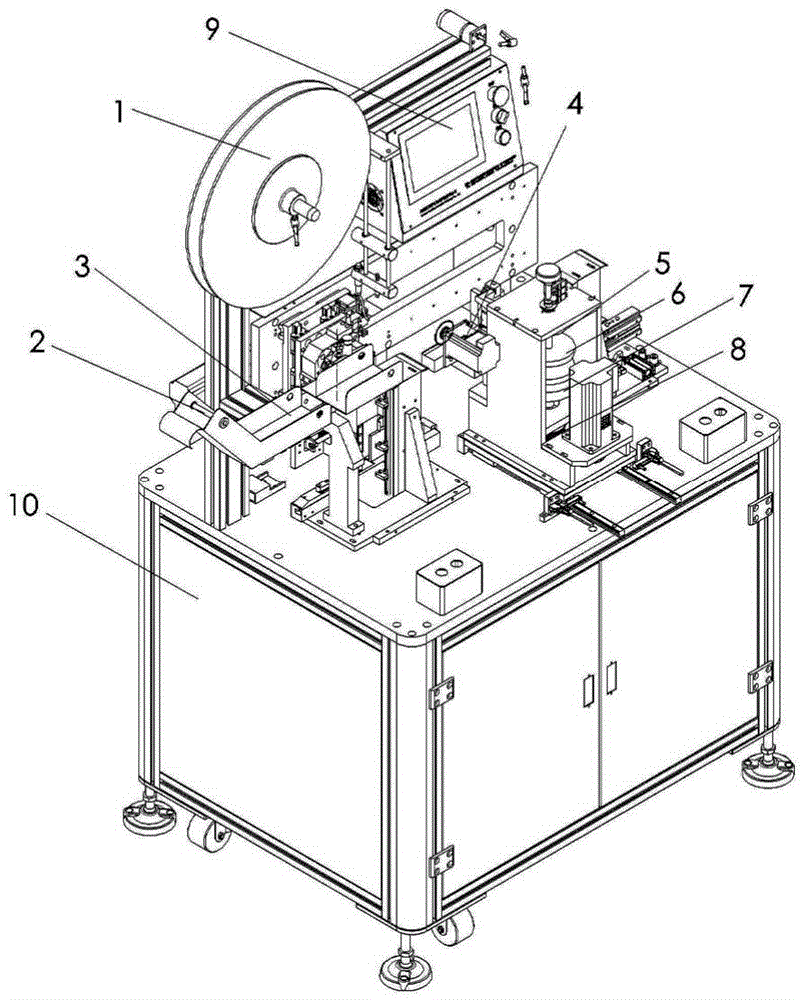

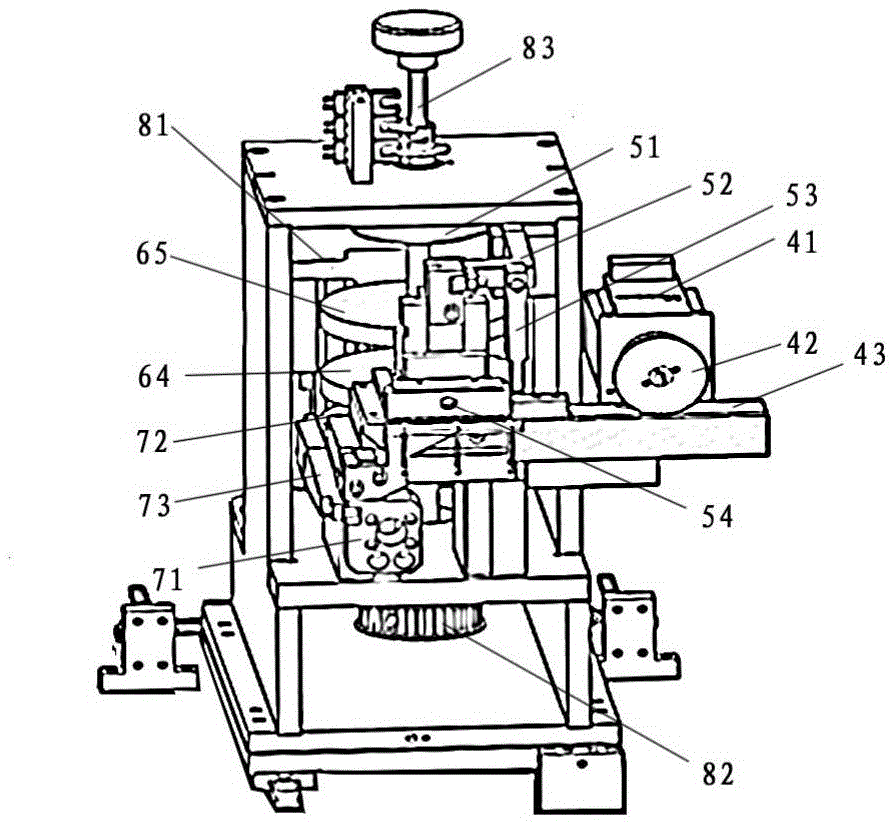

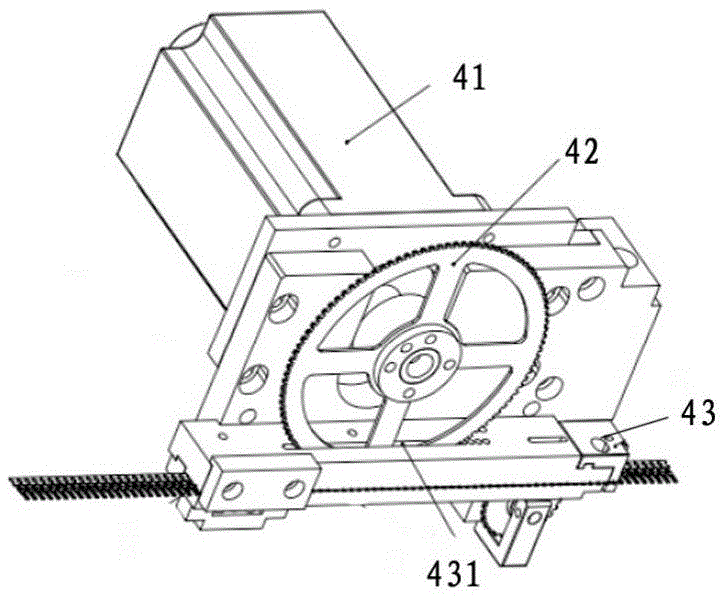

[0026] see Figure 1-9 As shown, the present invention relates to a FPC cam needle insertion machine, including a frame 10, a discharge tray 1 arranged on one side of the frame 10 for placing FPC to be inserted, and a feed roller 2 arranged below the discharge tray 1 , the transmission track 3 that is arranged on the frame 10 and connected with the discharge tray 1, the feeding mechanism 4 that is arranged on one side of the transmission track 3, and the pressing needle that is arranged on the side of the feeding mechanism 4 to press and fix the FPC to be plugged in Mechanism 5, the needle insertion mechanism 6, the cutting and bending mechanism 7, the transmission device 8, and the control assembly 9 for controlling the actions of the above-mentioned mechanisms, which are located under the needle pressing mechanism 5 and can take out the pins and insert them into the FPC to be inserted. The transmission device 8 includes a transmission servo motor 81, a cam transmission synch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com