Pressing machine for liner

A press-fitting machine and bushing technology, applied in the field of press machinery, can solve the problems of bushing hole deformation, low production efficiency, inaccurate positioning, etc., and achieve the effects of preventing violent collision, protecting equipment and protecting workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

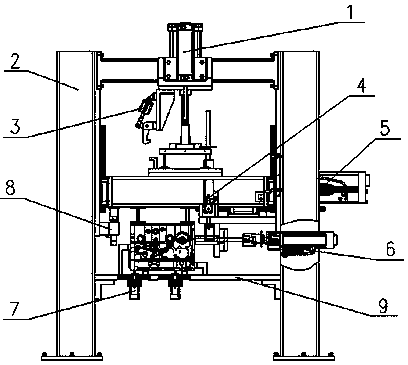

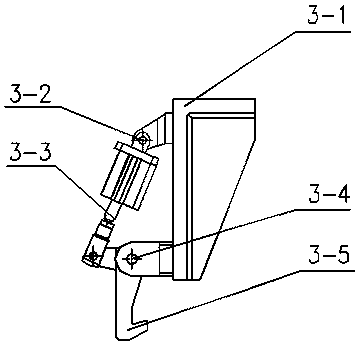

[0030] see figure 1 , the present invention includes a PLC control system, a clamping mechanism 1, a frame 2, an anti-falling mechanism 3, a feeding mechanism 4, a pushing mechanism 5, a pressing mechanism 6, a latch mechanism 7, a hydraulic buffer 8 and a working platform 9, clamping Tightening mechanism 1, bolt mechanism 7, anti-drop mechanism 3, feeding mechanism 4, pushing mechanism 5 and press-fitting mechanism 6 are all controlled by PLC control system.

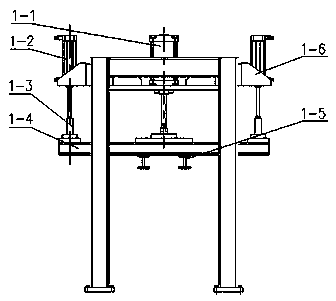

[0031] The frame 2 is a frame structure, and the frame structure is composed of a plurality of vertical beams connected with cross beams. The clamping mechanism 1 is arranged on the top of the frame 2, the pushing mechanism 5 is installed on the clamping mechanism, the feeding mechanism 4 and the pressing mechanism 6 are respectively connected with the pushing mechanism 5, the feeding mechanism 4 and the pressing mechanism 6 matching outfit. A working platform 9 for placing workpieces is erected on the lower part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com