Double-cylinder rotary compressor eccentrically assembling method

A technology of rotary compressors and assembly methods, which is applied in the direction of rotary piston machines, rotary piston pumps, mechanical equipment, etc., and can solve the problems of eccentric parts that lose precision, eccentric parts that do not meet the accuracy requirements, and time-consuming assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

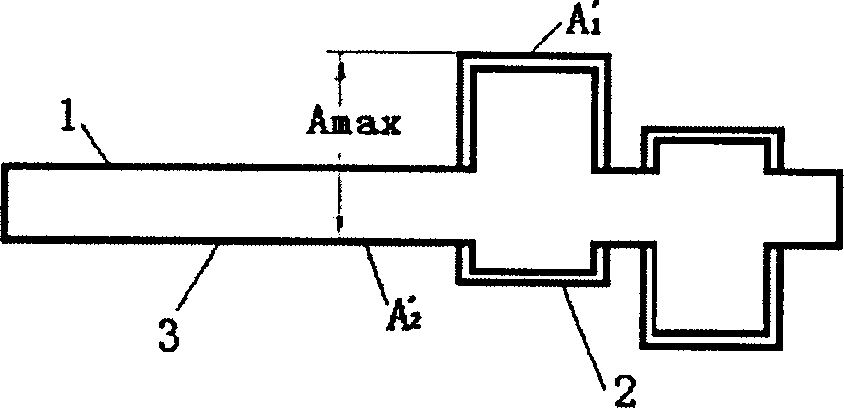

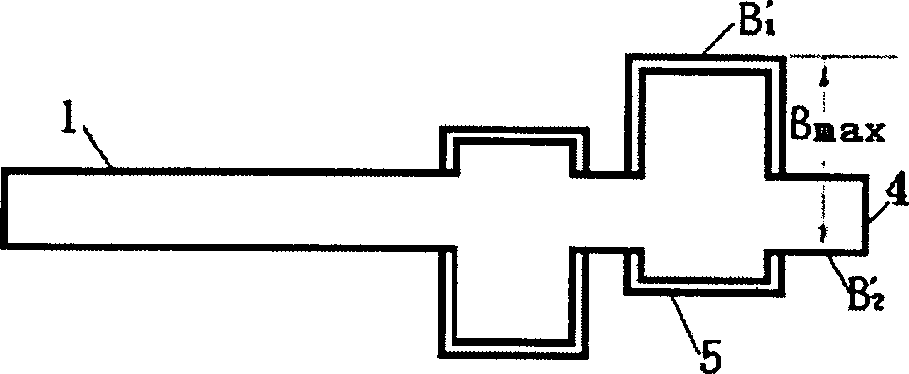

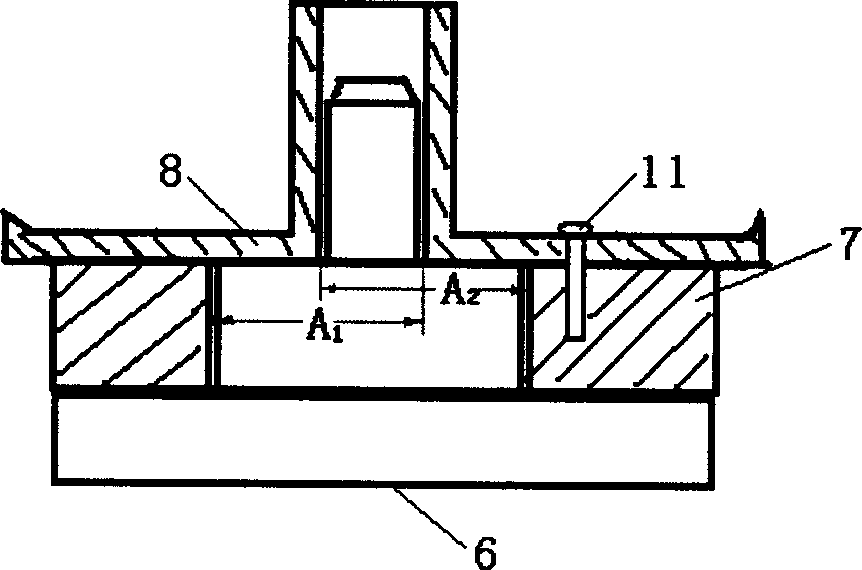

[0046]In this embodiment, the operation steps are roughly as follows: After assembling the upper and lower cylinder heads 8, 10 and the upper and lower cylinders 7, 9 respectively, assemble them into the crankshaft 1, the first and second pistons 2, 5 and the middle plate 20 (temporary assembly), then remove the lower cylinder head 10, fix the upper cylinder 7 and the lower cylinder 9 with fixing bolts 13, measure the second eccentric clearance, and finally install the upper and lower cylinder head 10 and the muffler 15 to complete the entire assembly. This embodiment shows the assembly method of the pump body of the double-cylinder rotary compressor, the measurement method of the inner diameter of the cylinder assembly and the eccentric clearance, and the detection means for detecting the second eccentric clearance. The entire assembly is as follows according to the device sequence Be explained.

[0047] First: The first step is to determine the first eccentric clearance (fit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com