Novel container fireproof and dampproof floor

A container, a new type of technology, applied in the direction of floor covering, application, coating, etc., can solve the problems of the impact on the health of personnel inside the container, poor waterproof and moisture-proof effect, and short service life of the floor, and achieve light weight, good mechanical strength, and barrier properties Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

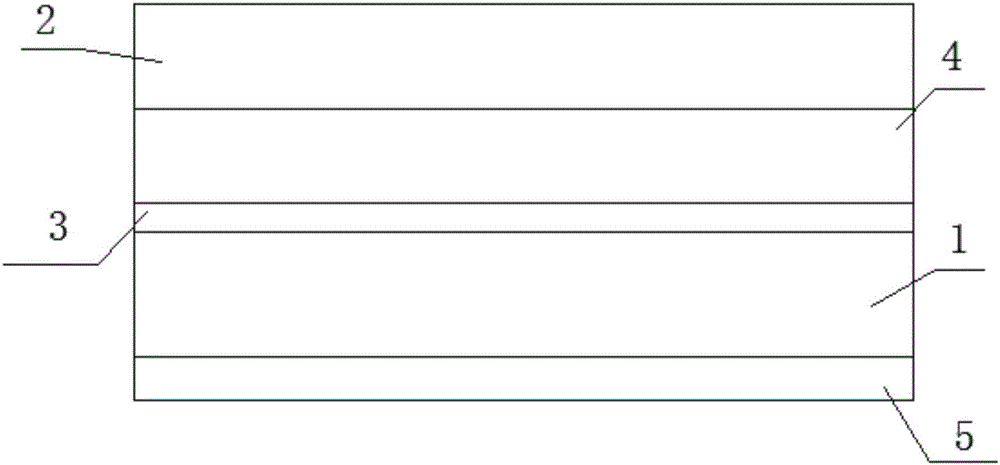

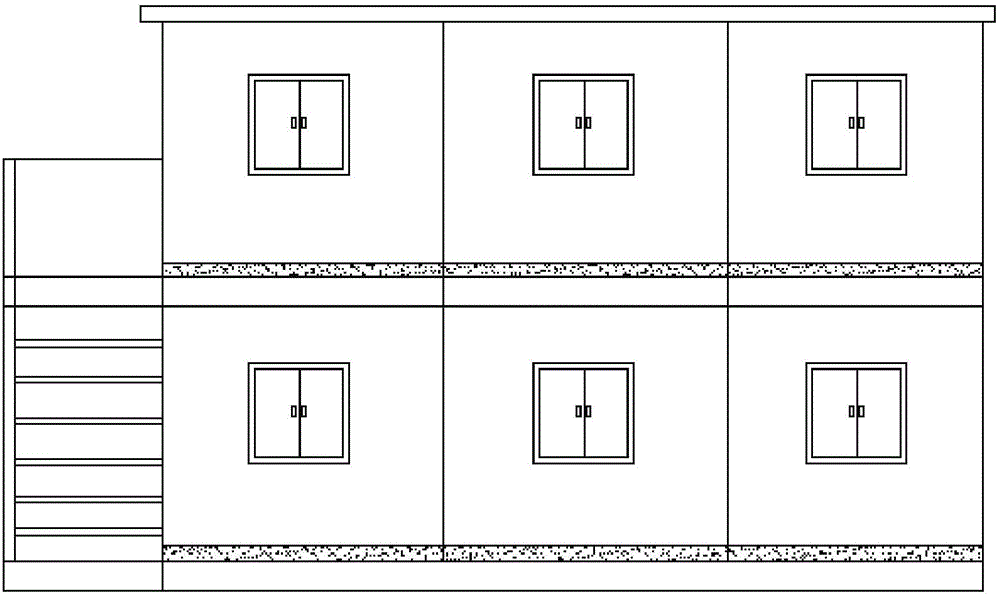

[0045] A kind of novel container fire-proof and moisture-proof floor of the present embodiment, such as figure 1 and figure 2 As shown, it includes a middle material layer 1, a waterproof layer 3 and a surface layer 2 connected sequentially from bottom to top, a mixing layer 4 is provided between the waterproof layer 3 and the surface layer 2, and the bottom of the middle layer 1 is provided There is an aluminum foil layer5. The whole structure of the present invention is simple, and the materials are all made of relatively light materials, which are compounded by various materials, so they have more functions. Wherein the aluminum foil layer 5 adopts soft aluminum foil as the raw material of the aluminum foil layer 5, and the soft aluminum foil has good mechanical strength, light weight, no thermal adhesion, not easy to be corroded, good barrier property, moisture-proof and waterproof, and gas Strong tightness and other advantages.

Embodiment 2

[0047] This embodiment is further defined on the basis of the above-mentioned embodiments, and there is a grid cloth layer between the middle material layer 1 and the aluminum foil layer 5 , the batter layer 2 and the mixed layer 4 . The mesh cloth adopts 5x5 purpose interwoven mesh cloth as the base material, thereby further improving the structural strength of the whole floor. Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

Embodiment 3

[0049] This embodiment is further defined on the basis of the above embodiments, and a non-woven fabric layer is further provided between the middle material layer 1 and the aluminum foil layer 5 . The non-woven fabric layer is composed of oriented or random fibers. It is a new generation of environmentally friendly materials. Features such as recycling. And its main function is to reduce the surface porosity of the product and facilitate the off-line of vacuum suction cup products. Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com