Permanent-magnet brushless direct-current hub motor having high efficiency and low material loss for electric vehicle

A permanent magnet brushless DC, hub motor technology, applied in the direction of electric vehicles, motors, electric components, etc., can solve the problem of affecting the output performance of the energy conversion efficiency of the motor, the unreasonable relationship between the stator and the rotor, and the design of the motor stator cogging structure Insufficient problems, to achieve the effect of high internal space utilization, high motor conversion efficiency, and reduced copper wire consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

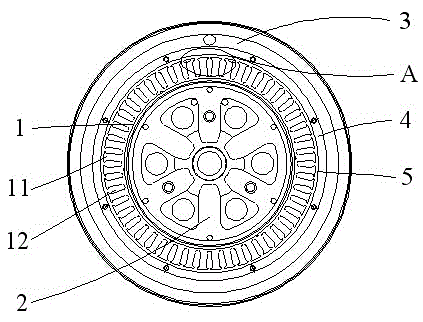

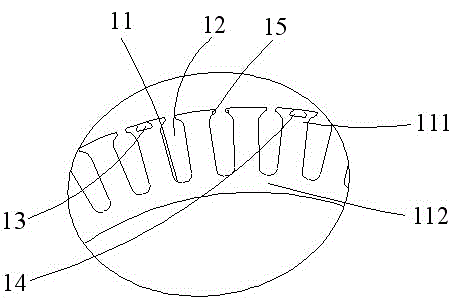

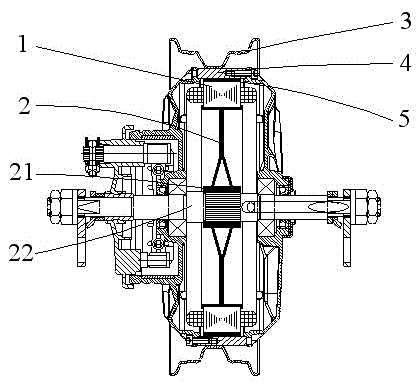

[0027] According to the above-mentioned overall structure, the laminated stator steel sheet 1 of the present invention is composed of a plurality of silicon steel sheets in the shape of a single punched sheet stack. The slot width of the cogged portion 12 is 2.2~2.3mm, and the third Hall slot 15 is respectively connected to the first The best angle of the Hall included angle formed between the Hall slot 13 and the second Hall slot 14 is 11°32', and the best thickness of the magnetic steel sheet 5 is 2.3 mm.

Embodiment 2

[0029] According to the above-mentioned overall structure, the laminated stator steel sheet 1 of the present invention is composed of a rolled silicon steel sheet blanking material tape, the slot width of the tooth slot 12 is 2.4~2.6mm, and the third Hall slot 15 is respectively the same as the first Hall slot. The best angle of the Hall included angle formed between 13 and the second Hall slot 14 is 11°32', and the best thickness of the magnetic steel sheet 5 is 2.3mm.

[0030] The invention adopts a 52-pole ratio and 48-slot ratio structure. By reducing the thickness of the magnetic steel sheet, the outer diameter of the laminated stator steel sheet is increased, the internal structure is optimized, the internal space is fully utilized, and the magnetic steel sheet is reduced. The amount increases the utilization rate of the magnetic steel sheet material, reduces the cost, and increases the use performance of the motor; the invention uses the principle of magnetic circuit satura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com