Carpet overedge machine head

A technology for hemming machines and carpets, which is applied in the direction of cloth pressing mechanism, sewing machine components, sewing machine control devices, etc. Easy-to-line, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following descriptions are only preferred embodiments of the present invention, and do not limit the protection scope of the present invention. The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

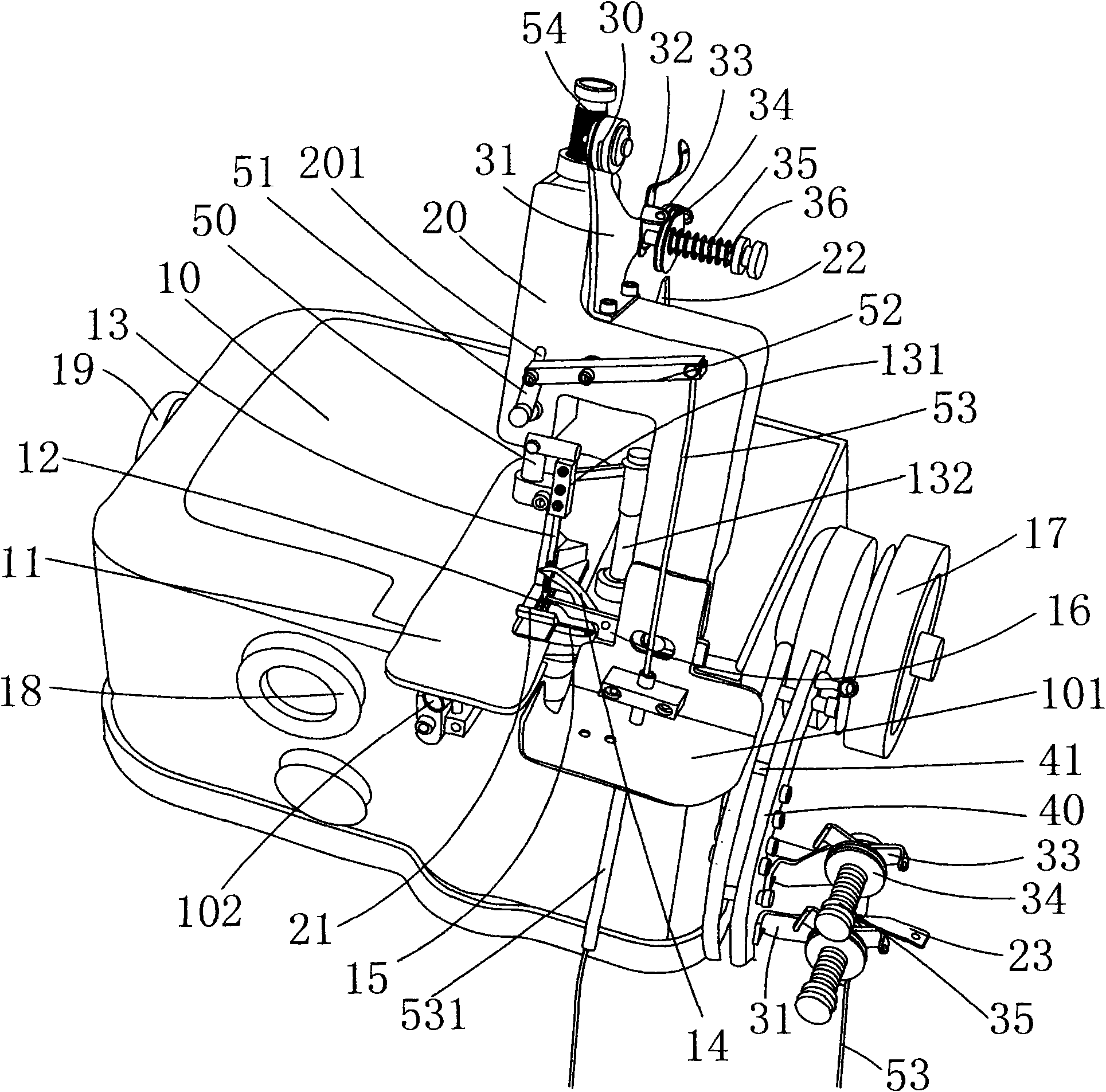

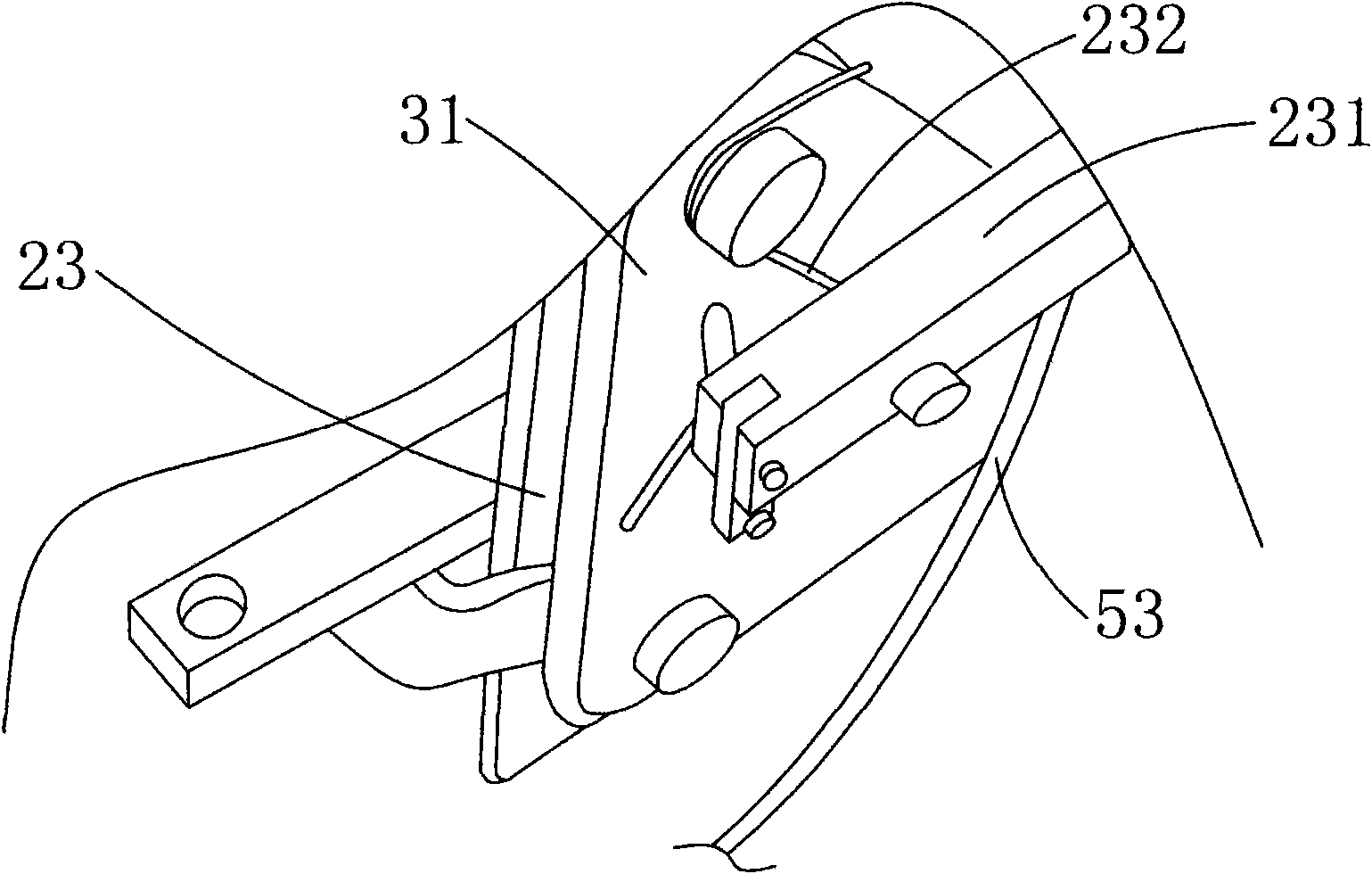

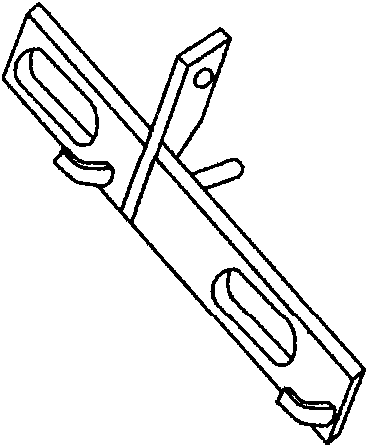

[0019] Examples, see Figure 1 to Figure 3 Shown: a head of a carpet hemming machine, including a chassis 10, a drive crankshaft arranged inside the chassis 10, a machine base 20, a presser foot 21, a presser foot lifting device, a needle plate 11, a cloth feeding tooth 12, and a machine needle 13 , Upper looper 14, lower looper 15, upper thread passing device and lower thread passing device. A baffle 16 is provided on the cabinet 10, and the hemming width of leather and thread fabrics can be adjusted by adjusting the position of the baffle 16. The side of the casing 10 is provided with a belt pulley 17, an oil inlet 18, a needle pitch regulator 19 and a lower thread passing device that cooperate with the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com