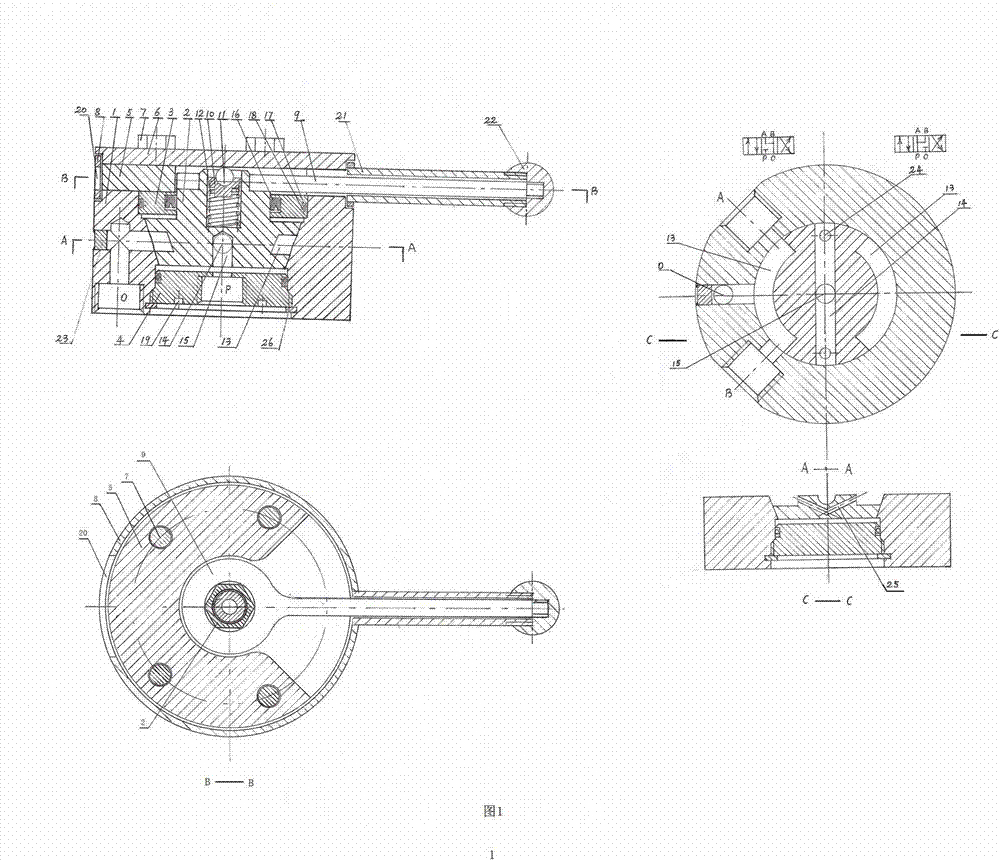

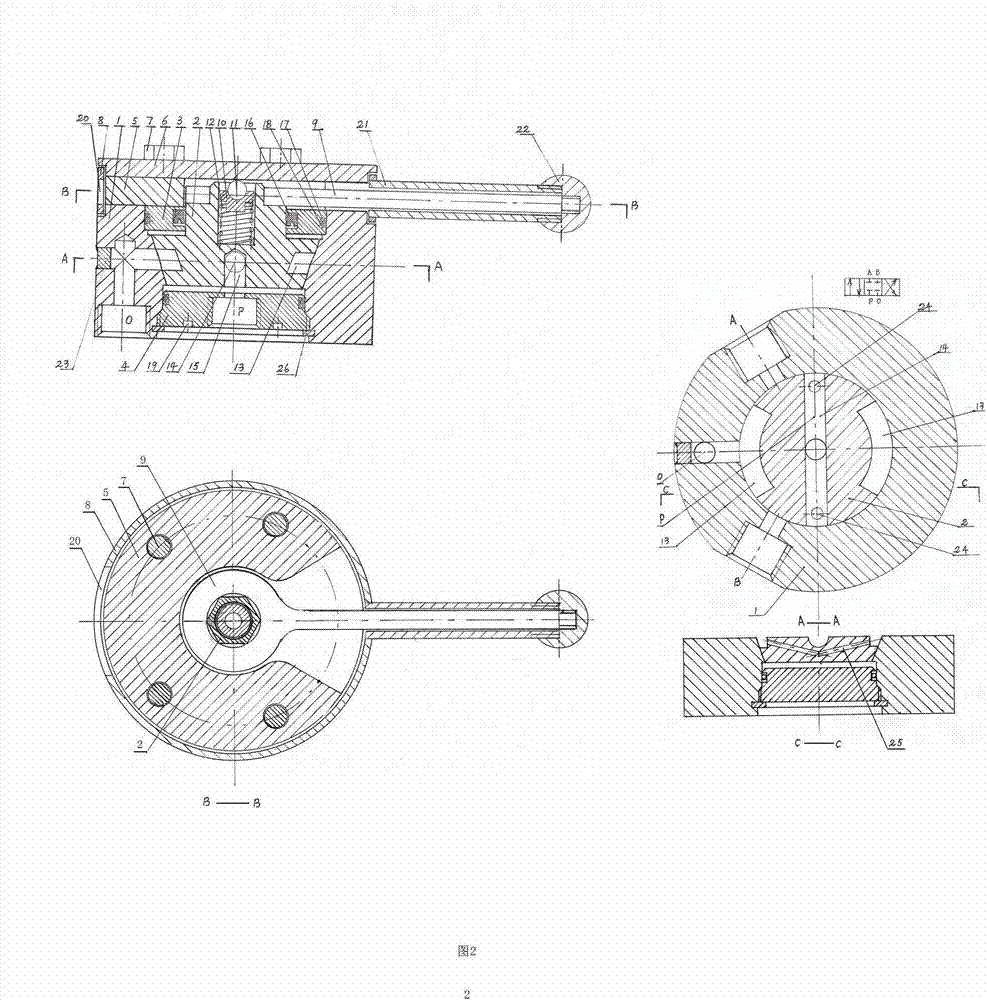

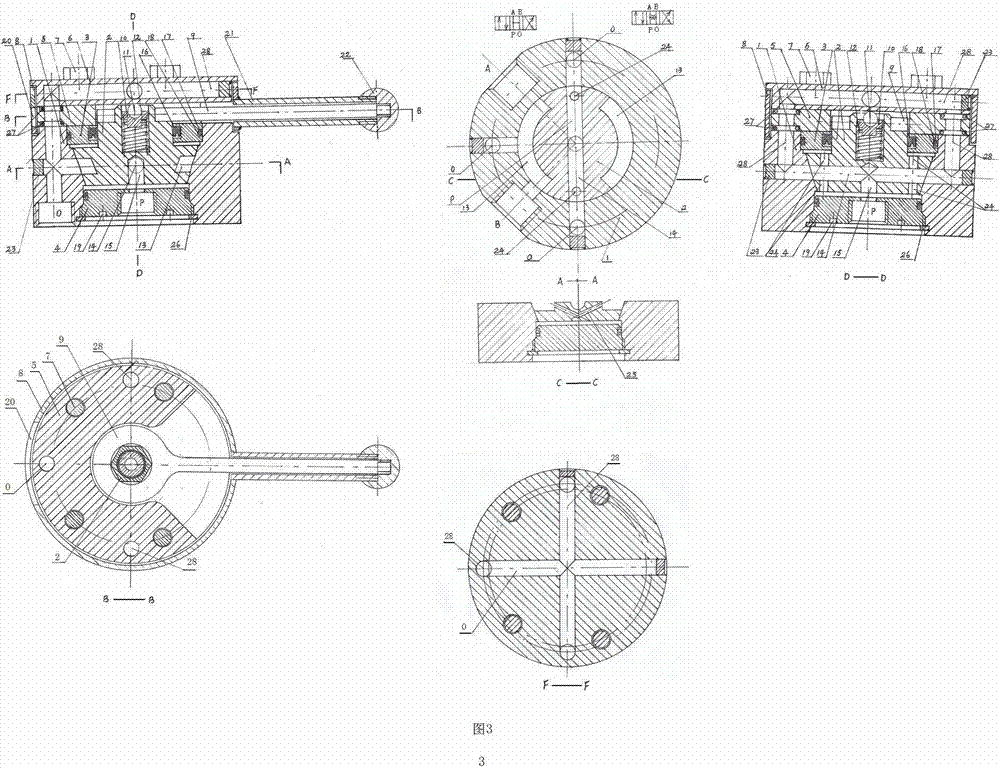

Tapered-surface reversing rotary valve

A technology of conical surface and rotary valve, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc. It can solve the problems of aggravated internal leakage, different structures of reversing valves, and cannot be used universally and interchangeably, so as to achieve wear resistance. Automatic compensating overlength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0045] Compared with the prior art, the fluid cone reversing rotary valve of the present invention has the characteristics of energy saving and long service life, and should be a good product for replacement of currently used products. It can bring economic benefits to users, how to get the invention from production to market, and finally get market approval is the ultimate goal of invention. In order to achieve this ultimate goal, the specific implementation methods are as follows:

[0046] 1. Propaganda through the relevant media, so that the staff engaged in this field can get information.

[0047] 2. Find out the breakthrough point to enter the market. It should be the first to process and manufacture the varieties with large market consumption and short replacement cycle, and try to sell them to these users. During the use of users, high-quality after-sales service and high-quality products Performance will surely win a good reputation from users, thereby speeding up mar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com