An automatic shrimp peeling machine

A shrimp peeling machine, automatic technology, applied in the field of automatic shrimp peeling machine, can solve the problems of change, internal thread residue, pressure instability and other problems, and achieve the effect of accurate working position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following is a detailed description of the technical solution of the present invention through the drawings.

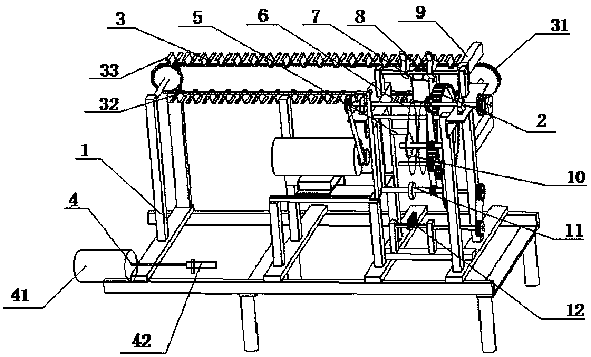

[0032] Such as figure 1 As shown, the present invention provides an automatic shrimp shelling machine, which is characterized in that: the shelling machine includes a frame 1 and a main transmission gear 2, a conveying device 3, a transmission device, a cam system, and a main transmission gear installed on the frame 1. In the water spray system 4, the main transmission gear 2 is sleeved on the main transmission shaft 5, and the main transmission shaft 5 is also sleeved with two corresponding plane cams 6, and the plane cam 6 is provided with several sizes outside the circumference The pliers clamping device 7 and the tail stage separating device 8 are fixed on the large and small pliers clamping device 7, and the large and small pliers clamping device 7 is fixed in the main transmission gear 2 by a bolt On the side, a conveying device 3, a guiding roller devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com