Alumina ceramic and preparation method thereof

A technology of alumina ceramics and alumina, which is applied in the field of alumina ceramics and its preparation, can solve the problems of low flexural strength of 75 alumina ceramics, achieve the effects of reducing migration and relaxation, low sintering temperature, and improving surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

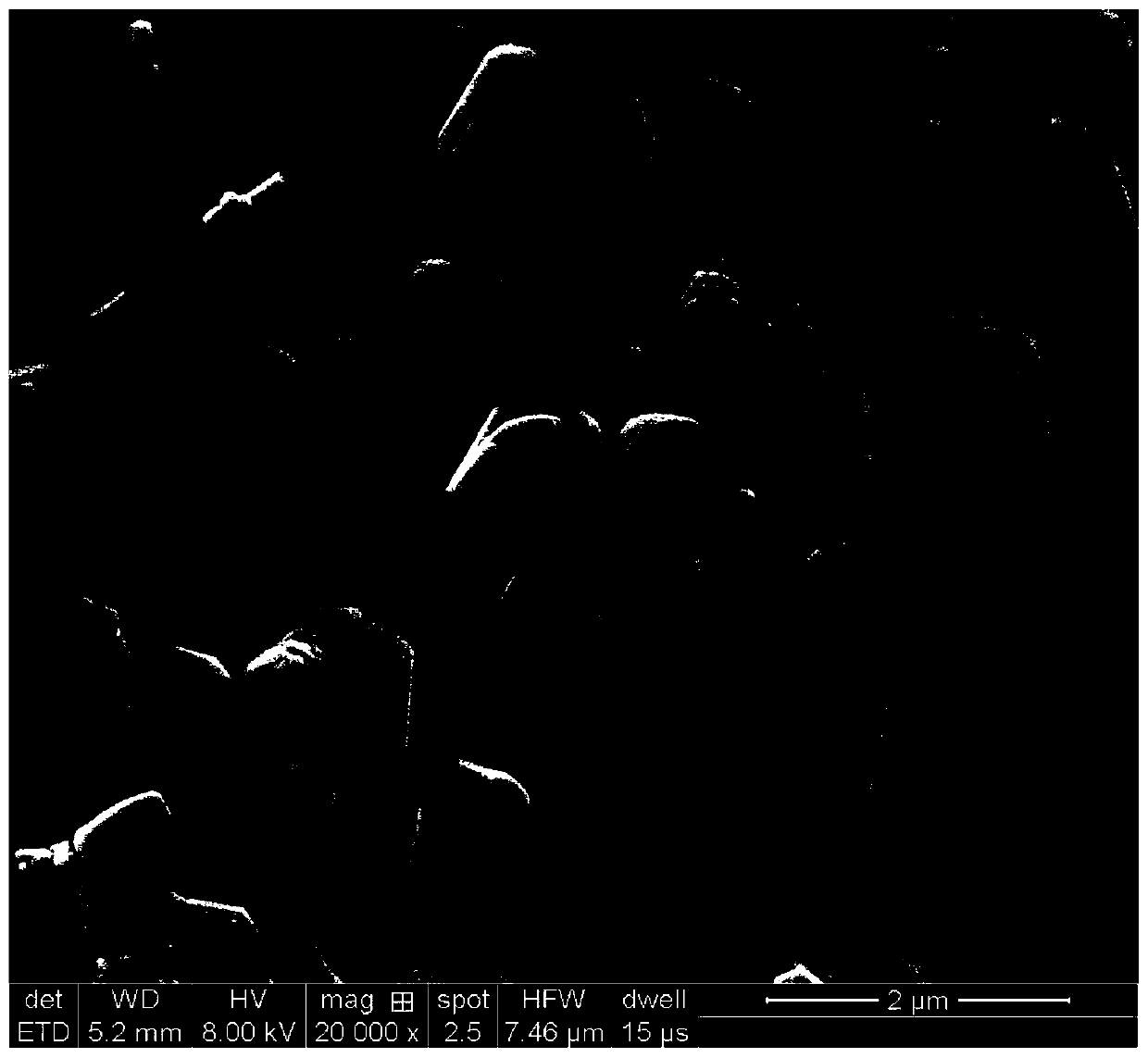

Image

Examples

Embodiment 1

[0026] The alumina ceramics of this embodiment is made of the following raw materials in parts by weight: 40 parts of alumina, 13 parts of calcined kaolin, 2 parts of bentonite, 2 parts of heavy magnesium carbonate, 2 parts of calcium carbonate, 2.3 parts of barium carbonate, 0.3 parts of glycerin 0.3 parts of emulsifying wax, 0.8 parts of titanium dioxide, 5 parts of zirconium dioxide and 0.5 parts of lanthanum oxide.

[0027] This embodiment also provides a method for preparing the above-mentioned alumina ceramics, the method comprising the following steps:

[0028] Step 1. Mix alumina, calcined kaolin, bentonite, heavy magnesium carbonate, calcium carbonate, barium carbonate, glycerin, emulsified wax, titanium dioxide, zirconium dioxide and lanthanum oxide to obtain a mixture, and add ball mill and water to the mixture After ball milling for 2.5 hours, adding a mass fraction of 10% polyvinyl alcohol aqueous solution, and then ball milling for 0.5 hours, passing through a 60...

Embodiment 2

[0037] The alumina ceramics of this embodiment is made of the following raw materials in parts by weight: 36 parts of alumina, 9 parts of calcined kaolin, 1 part of bentonite, 1 part of heavy magnesium carbonate, 1 part of calcium carbonate, 3 parts of barium carbonate, 0.5 parts of glycerin 0.5 parts of emulsifying wax, 1.0 parts of titanium dioxide, 8 parts of zirconium dioxide and 0.4 parts of lanthanum oxide.

[0038] This embodiment also provides a method for preparing the above-mentioned alumina ceramics, the method comprising the following steps:

[0039] Step 1. Mix alumina, calcined kaolin, bentonite, heavy magnesium carbonate, calcium carbonate, barium carbonate, glycerin, emulsified wax, titanium dioxide, zirconium dioxide and lanthanum oxide to obtain a mixture, and add ball mill and water to the mixture After ball milling for 3 hours, add a polyvinyl alcohol aqueous solution with a mass fraction of 10%, and then ball mill for 0.5 h, pass through a 60-mesh sieve to...

Embodiment 3

[0045] The alumina ceramics of this embodiment is made of the following raw materials in parts by weight: 46 parts of alumina, 16 parts of calcined kaolin, 3 parts of bentonite, 3 parts of heavy magnesium carbonate, 3 parts of calcium carbonate, 1 part of barium carbonate, 0.1 parts of glycerin 0.1 part of emulsifying wax, 0.5 part of titanium dioxide, 2 parts of zirconium dioxide and 0.6 part of lanthanum oxide.

[0046] This embodiment also provides a method for preparing the above-mentioned alumina ceramics, the method comprising the following steps:

[0047] Step 1. Mix alumina, calcined kaolin, bentonite, heavy magnesium carbonate, calcium carbonate, barium carbonate, glycerin, emulsified wax, titanium dioxide, zirconium dioxide and lanthanum oxide to obtain a mixture, and add ball mill and water to the mixture After ball milling for 2 hours, add a mass fraction of 10% polyvinyl alcohol aqueous solution, then ball mill for 0.5 h, pass through a 60-mesh sieve to obtain a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com