High precision machining method for double-head cross hole in bolt shaft

A high-precision machining and cross-crossing technology, which is applied to metal processing equipment, manufacturing tools, and drilling molds for workpieces, can solve the problems of cross-hole machining that cannot be perpendicular to each other, rework, and improper installation, etc., to achieve It is conducive to quick response, improved efficiency, and easy plug-in and plug-in effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

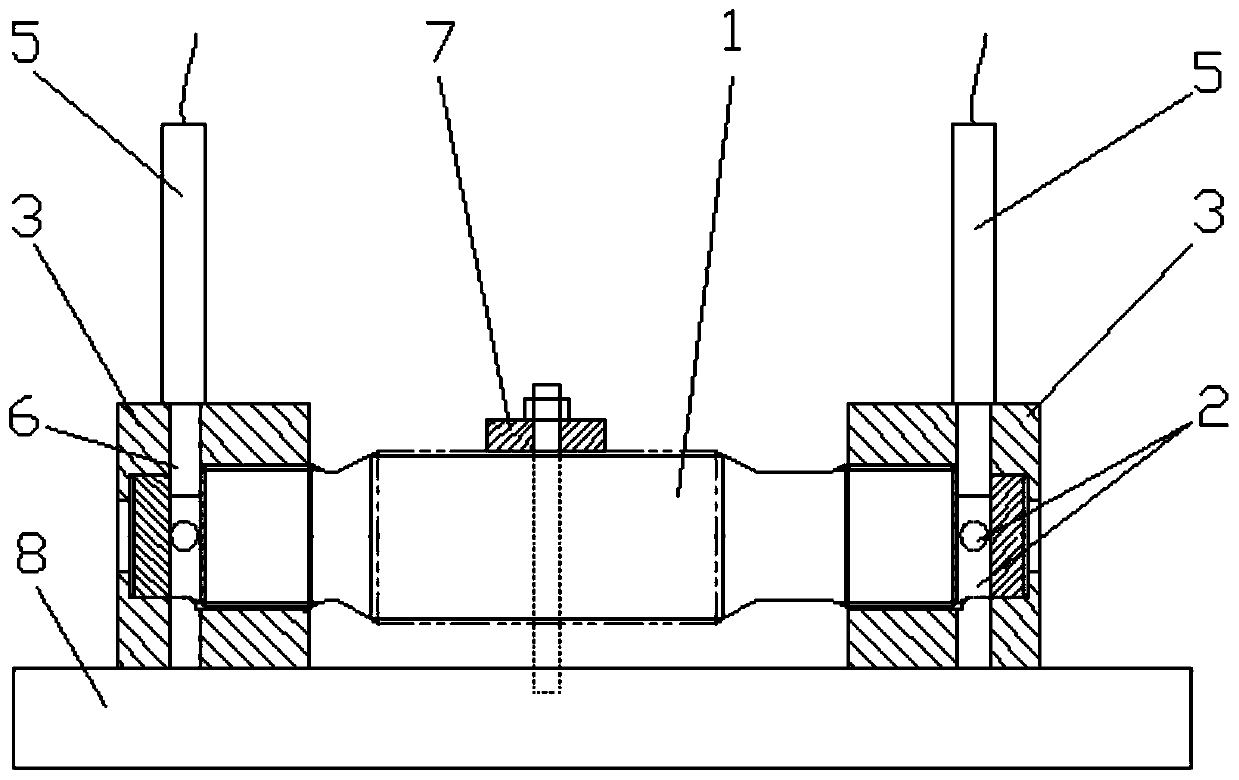

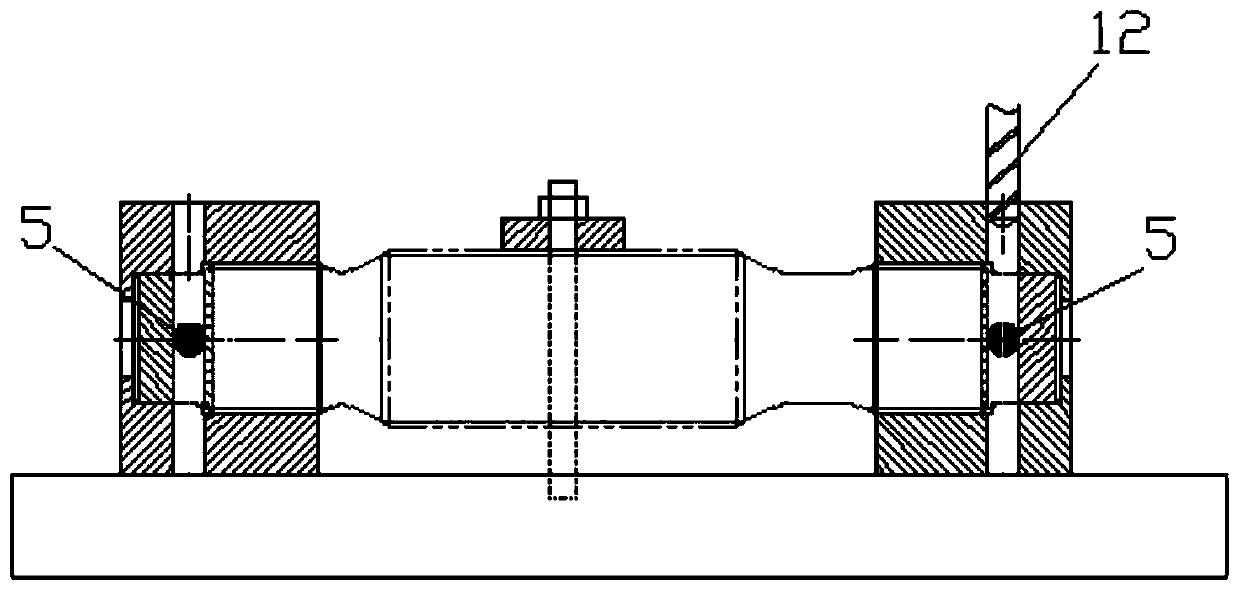

[0035] Such as Figures 1 to 6 Shown is an embodiment of a high-precision machining method for a double-headed cross hole on a bolt shaft of the present invention, including the following steps:

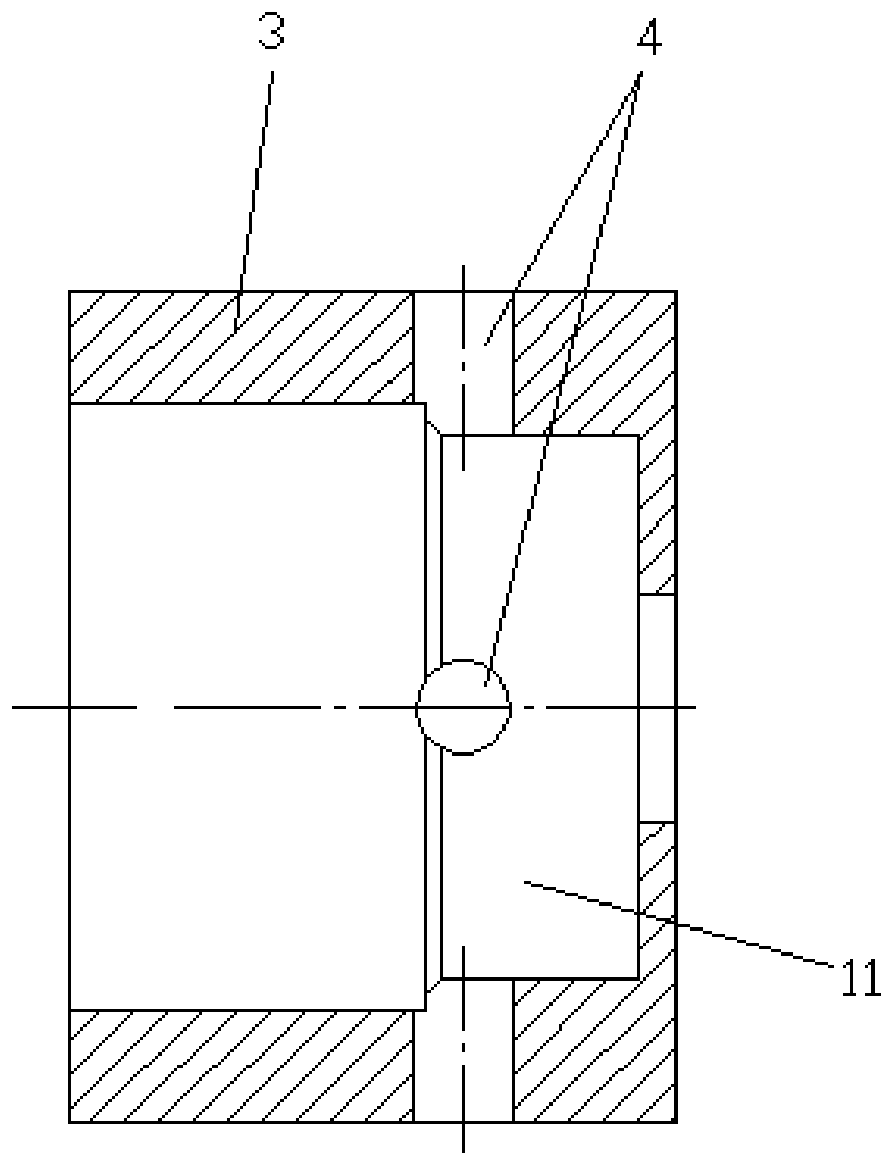

[0036] (1) Drilling template making: design and manufacture a pair of cross hole drilling templates 3 for drilling cross holes 2 at both ends of the bolt shaft 1, the cross hole drilling template 3 is a flipping drilling template with a 90-degree flip surface; The cross-hole drilling template 3 is positioned with the outer circle of both ends of the bolt shaft 1, and is provided with two guide holes 4 located in the cross direction, and the inner diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com