Production technology for impregnated interwoven fabric

A production process and technology of interweaving cloth, which is applied in the field of production technology of dipped interweaving cloth, can solve the problems of low bonding force between cloth and glue, unusable corners of cloth, and large deviation of cutting line, etc., achieving high accuracy and saving Energy, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

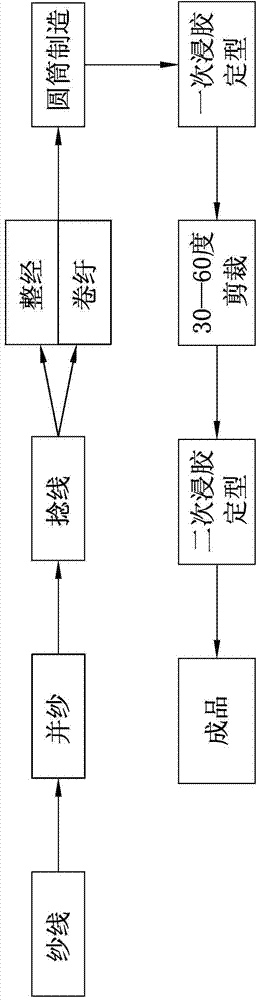

[0015] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 :

[0016] A production process of rubber-impregnated interwoven fabric. After the yarn is combined, twisted, warped and rolled, the cylindrical cloth is produced by a cylindrical loom. Cut the strip cloth at an angle of 45 degrees, and after the cut strip cloth is dipped twice in the warp direction, it will be stretched and shaped to form a wide-angle cloth product with the included angle of 20-40 degrees or 140-160 degrees. ; Wherein: the parts by weight of the formula used for primary dipping are: 0.5-2 parts of polyvinyl alcohol, 98-99.5 parts of water, after weighing and mixing the above-mentioned polyvinyl alcohol and water, adjust the pH value to 7-8 to form a primary dipping Glue solution; the parts by weight of the formula used for secondary dipping are: ① 5 ± 0.1 parts of natural latex, ② 20 ± 0.1 parts of butylpyridine latex,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com