Fluorinion-doped lithium iron phosphate material and preparation methods thereof

A lithium iron phosphate and fluoride ion technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problem of reducing the utilization rate of lithium iron phosphate active materials, the conductivity of lithium iron phosphate ions has little effect, and the calcination temperature increases economic costs, etc. problem, to achieve the effect of low cost of raw materials, easy industrial production, and improved rate charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Lithium carbonate, ferric oxide, diammonium hydrogen phosphate and ammonium fluoride according to the molar ratio of Li + : Fe 3+ :PO 4 3- :F - =1.05: 1: 0.95: 0.15 Weighing, add soluble starch according to 15% of the mass of ferric oxide, then add absolute ethanol according to 150% of the total mass of the reactant material, ball mill and mix for 6 hours to obtain a uniform slurry , then put it in a well-type furnace protected by a nitrogen atmosphere, heat up to 300°C at a rate of 2°C / min for pre-sintering, and keep it for 8 hours; then heat it up to 650°C at 10°C / min for calcination, keep it 24 hours. Naturally cool to room temperature with the furnace, take out, grind and sieve (400 mesh), and obtain fluoride ion-doped lithium iron phosphate material.

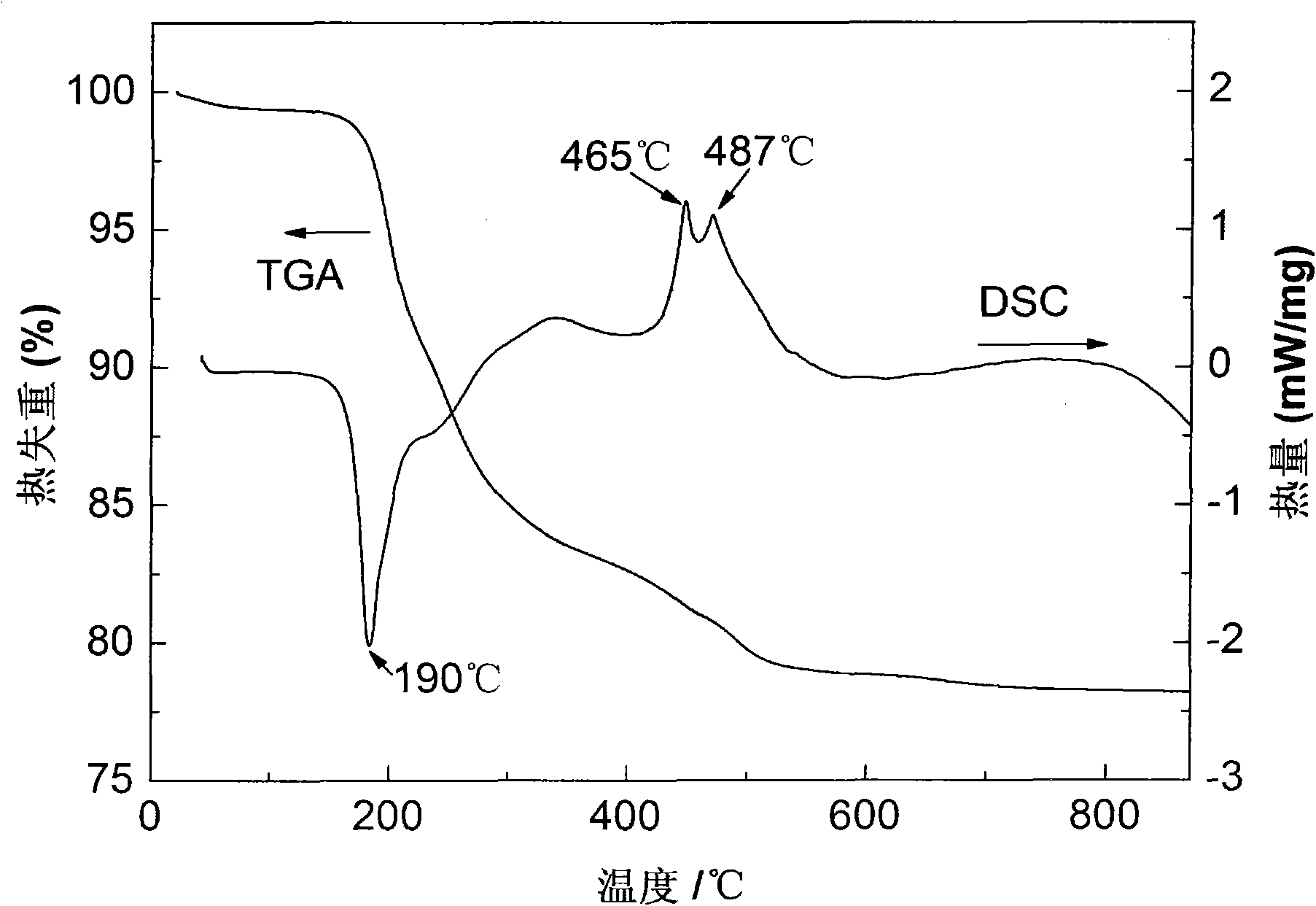

[0045] The results of thermal reaction analysis of the above-mentioned pre-sintered material (after ball milling and mixing) are as follows: figure 1 shown. Depend on figure 1 It can be seen that there are tw...

Embodiment 2

[0050] Lithium acetate, ferrous oxalate, ammonium dihydrogen phosphate and sodium fluoride according to the molar ratio of Li + : Fe 2+ :PO 4 3- : F-=0.97: 1: 0.99: 0.03 Weighing, add glucose according to 5% of the mass of ferrous oxalate, then add deionized water according to 100% of the total mass of the reactant material, ball mill and mix for 4 hours to obtain a uniform slurry , then put it in a well-type furnace protected by a nitrogen atmosphere, heat up to 200°C at a rate of 1°C / min for pre-sintering, and keep it for 2 hours; then heat it up to 450°C at 5°C / min for calcination, keep it 12 hours. Naturally cool to room temperature with the furnace, take out, grind and sieve (400 mesh), and obtain fluoride ion-doped lithium iron phosphate powder material.

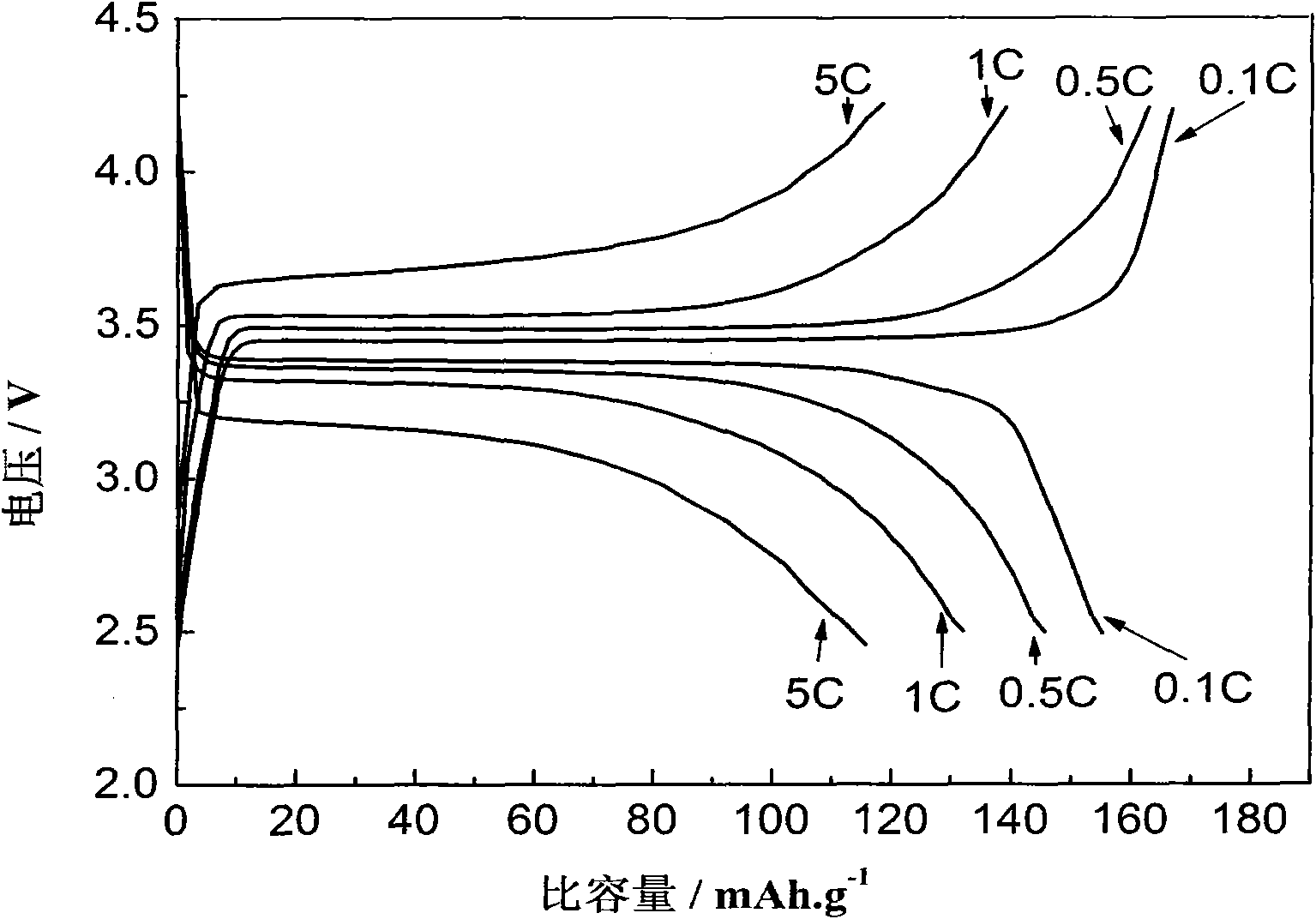

[0051] The fluoride ion-doped lithium iron phosphate material prepared by the above method is used as the positive electrode active material to make the positive electrode film. The positive electrode film is compo...

Embodiment 3

[0053] Lithium oxalate, iron nitrate, ammonium phosphate, and lithium fluoride were mixed according to the molar ratio of Li + : Fe 3+ :PO 4 3- : F-=0.87: 1: 0.95: 0.15 Weighing, add sucrose by 50% of ferric nitrate quality, then add acetone by 300% of the total mass of reactant material, ball mill and mix for 8 hours, obtain mixed uniform slurry, then It is placed in a well-type furnace protected by an argon atmosphere, and the temperature is raised to 350°C at a heating rate of 3°C / min for pre-sintering, and the temperature is kept for 10 hours; then the temperature is raised to 550°C at 15°C / min for calcination, and the temperature is kept for 30 hours. . Naturally cool to room temperature with the furnace, take out, grind and sieve (400 mesh), and obtain fluoride ion-doped lithium iron phosphate powder material.

[0054] The fluoride ion-doped lithium iron phosphate material prepared by the above method is used as the positive electrode active material to make the posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| First discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com