Warp and weft forwards and backwards entwisted white body wide-angle interwoven fabric

A technology of forward and reverse twisting, warp and weft threads, used in fabrics, textiles, textiles and papermaking, etc., can solve problems such as low service life, poor flexural resistance, and large internal peristalsis, so as to improve service life, reduce binding force, internal Small creep effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

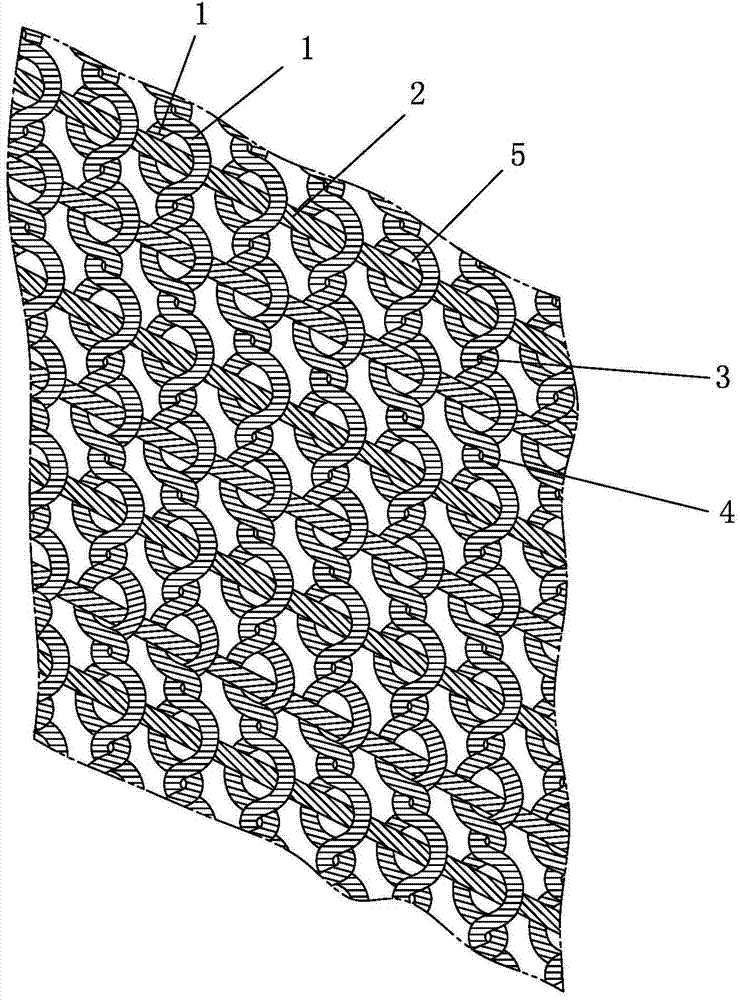

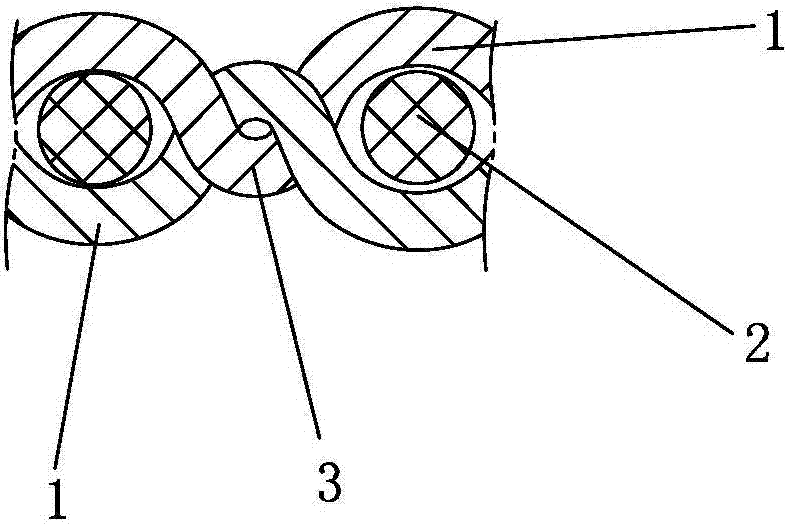

[0016] The present invention will be further described below with specific embodiment, see figure 1 -2:

[0017] Longitudinal and reverse-twisted white blank wide-angle interwoven fabric is a white fabric woven from warp 1 and weft 2 at an angle of 20°-40° or 140°-160°, and the warp 1 is formed by twisting raw material silk A positive twist yarn and an anti-twisted yarn formed by twisting two raw material filaments, the weft 2 is a positive twist yarn formed by twisting the raw material filaments and an anti-twisted yarn formed by twisting the raw material filaments, the warp 1, The wefts 2 are arranged at intervals of positive twist and reverse twist or are arranged at intervals of reverse twist and positive twist. The two warp threads 1 form a group, and the warp directions of the two warp threads 1 of each group are arranged according to the direction of forward twist 360° and reverse twist 360°. ° There are positive kink points 3 and anti-kink points 4 arranged at interva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com