Cold repairing, asphalt mixture and its manufacturing method

A technology of cold patching asphalt and mixture, which is applied in the field of asphalt mixture and asphalt mixture manufacturing, and can solve the problems that emulsified asphalt materials cannot be used for large-scale construction of high-grade road surface maintenance, road maintenance restrictions, and inconvenient construction. Achieve excellent high temperature stability, improve properties, and strong wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

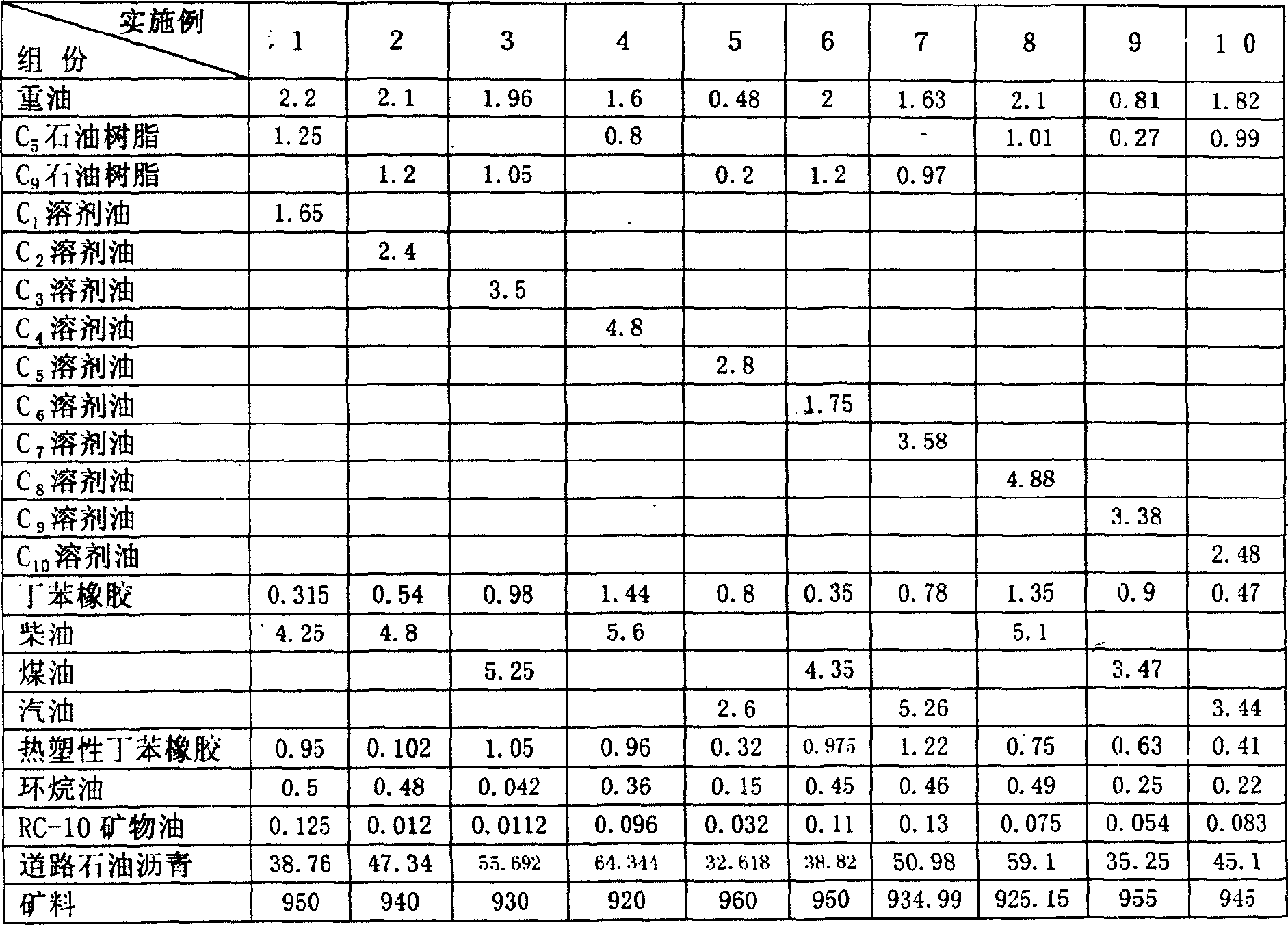

[0052] The composition of the cold-patch asphalt mixture of the present invention and its content in parts by weight are as follows:

[0053]

[0054] Mineral materials, according to the JTJ052-2000 (transfer) asphalt mixture mineral material grading and asphalt dosage range (square hole sieve), the grades of mineral materials are coarse-grained AC-30 I, II, AC-25 I, II, medium-grained AC-20 I, II, AC-16 I, II, fine grain AC-13 I, II, AC-10 I, II, sand grain AC-5 I, II; extra coarse AM-40, coarse grain AM-30, AM-25, medium grain AM-20, AM-16, fine grain AM-13, AM-10.

[0055] The manufacture method of cold patch asphalt mixture of the present invention is as follows:

Embodiment 4、5、9

[0056] The manufacture method of embodiment 4,5,9:

[0057] (1) Preparation of prepolymer A:

[0058] Put the heavy oil into the jacketed stainless steel reaction kettle, and when the temperature rises to 75-85°C, add C 5 or C 9 Petroleum resin, continue to heat up, when the temperature rises to 85-95 ° C, start the high-speed mixer, and shear and mix in the reactor for 20-40 minutes to obtain prepolymer A.

[0059] (2) Preparation of prepolymer B:

[0060] Will C 4 or C 5 or C 9 Add solvent oil into the closed enamel reaction kettle and heat up to 40-50°C, add styrene-butadiene rubber, continue to heat up to 70-80°C, start the high-speed shearing machine, and shear and disperse in the reaction kettle to obtain a prepolymer b.

[0061] (3) Preparation of prepolymer C:

[0062] Add diesel oil or gasoline into a closed stainless steel reaction kettle. When the temperature rises to 30-50°C, add thermoplastic styrene-butadiene rubber. After constant heat for 20-40 minutes,...

Embodiment 3、7、8、10

[0067] The manufacture method of embodiment 3,7,8,10:

[0068] (1) Preparation of prepolymer A:

[0069] Put the heavy oil into the jacketed stainless steel reaction kettle, and when the temperature rises to 75-85°C, add C 5 or C 9 Petroleum resin, continue to heat up, when the temperature rises to 95-100 ° C, start the high-speed mixer, and shear and mix in the reactor for 25-35 minutes to obtain prepolymer A.

[0070] (2) Preparation of prepolymer B:

[0071] Will C 3 or C 7 or C 8 or C 10 Add solvent oil into the closed enamel reaction kettle and heat up to 40-50°C, add styrene-butadiene rubber, continue to heat up to 70-80°C, start the high-speed shearing machine, and shear and disperse in the reaction kettle to obtain a prepolymer b.

[0072] (3) Preparation of prepolymer C:

[0073] Add diesel oil or gasoline into a closed stainless steel reaction kettle. When the temperature rises to 30-50°C, add thermoplastic styrene-butadiene rubber. After constant heat for 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com