Method for regulating fan-shaped section roller seams of continuous casing machine by using mathematical model

A technology of continuous casting machine segment and mathematical model, applied in the field of continuous casting equipment, can solve the problems of low work efficiency and high labor intensity, and achieve the effects of improving work efficiency, widening application prospects and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

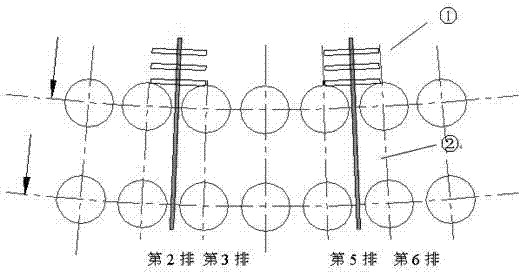

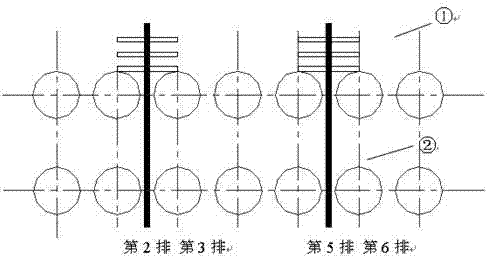

[0059] Adjust section B of the fan-shaped section, and check the maintenance regulations to know that the target roll gap of this fan-shaped section is: the entrance roll gap is 238.4mm, the exit roll gap is 237.8mm, and the current actual measurement: the entrance roll gap is 239.58mm, the exit roll gap is 238.12mm,

[0060] Then, calculate the actual and target roll gap difference

[0061] Δimport=-1.18, Δexport=-0.32,

[0062] According to mathematical simulation 3 / 4X-1 / 3Y=-1.18

[0063] 3 / 4Y-1 / 3X=-0.32

[0064] Solved; X=-2.2, Y=-1.4

[0065] Then the gasket needs to be pulled out by 2.2mm at the inlet clamping hydraulic cylinder, and the gasket needs to be removed by 1.4mm at the outlet clamping hydraulic cylinder. Using EXCEL, based on the mathematical simulation of the roll gap of the continuous casting segment, the attached Figure 8 Quick calculation form, when adjusting the roll gap value of the fan section, only need to input the target roll gap value and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com