Method for producing hot rolled steel strip for automotive frame

A technology for automobile beams and steel strips is applied in the field of producing hot-rolled steel strips to achieve the effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

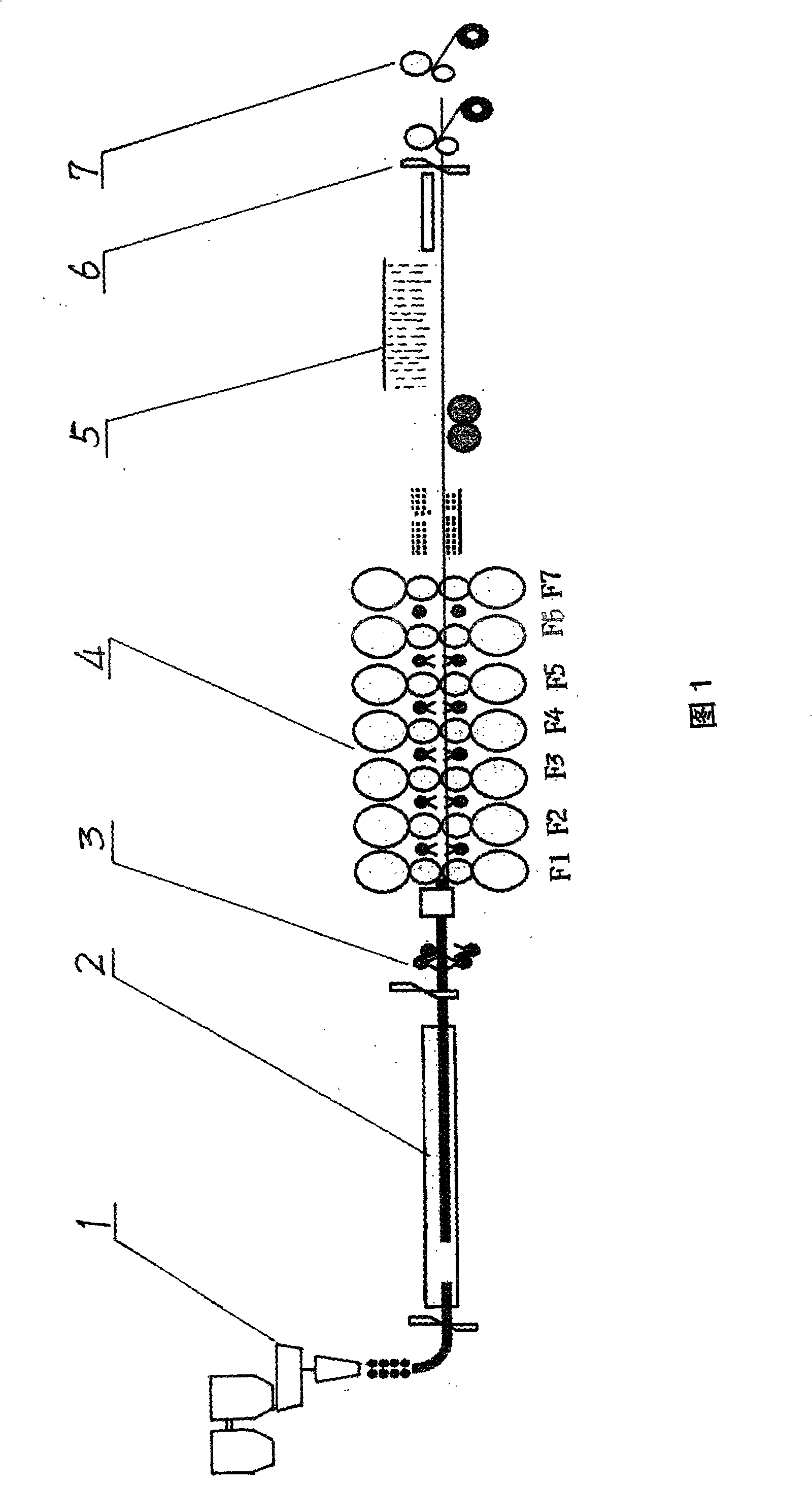

Image

Examples

Embodiment 1

[0041] Adopt CSP thin slab continuous casting and rolling process to produce 510L automobile frame steel coil (band), its finished product composition design (wt%): C=0.03-0.07, Si=0.20-0.35, Mn=1.2-1.4, Nb= 0.02-0.04, Ti=0.015-0.03, P≤0.025, S≤0.012.

[0042] Conventional smelting is carried out in a 100t oxygen top-bottom compound blowing converter, and argon is blown from the bottom throughout the process. Control the end point composition of molten steel: [C]=0.01-0.04%, [Si]=0.10-0.20%, [Mn]=0.85-1.0%, [P]≤0.015%, [S]≤0.012%.

[0043] When the final temperature of the molten steel in the converter and the composition of the molten steel are qualified, the steel is tapped, and the molten steel in the converter is sent to the LF furnace for refining. Firstly, aluminum particles are added to the molten steel to remove the oxygen content in the molten steel and the temperature of the molten steel is controlled at about 1600°C. For argon blowing, first stir the molten steel w...

Embodiment 2

[0047] Adopting CSP thin slab continuous casting and rolling process to produce 590L steel coil (strip) for automobile frame, composition design (wt%) of 590L hot-rolled steel coil (strip) for automobile frame: C=0.03-0.07, Si=0.20-0.35 , Mn=1.2-1.5, Nb=0.04-0.06, Ti=0.02-0.04, V=0.04-0.06, P≤0.025, S≤0.012.

[0048] Conventional smelting in oxygen top-bottom combined blowing converter, argon (Ar) is blown at the bottom throughout the whole process to ensure good bottom blowing and stirring, and control the end point composition of molten steel: [C]=0.01-0.04%, [Si]=0.10-0.20%, [ Mn]=0.85-1.0%, [P]≤0.015%, [S]≤0.012%.

[0049]When the end temperature of the converter molten steel and the composition of the molten steel meet the requirements, the slag is poured out and the converter molten steel is sent to the refining station for refining. In the molten steel refining process, aluminum particles are first added to the molten steel to remove the oxygen content in the molten st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com