Method for plugging dummy bar head of slab caster

A slab continuous caster and dummy head technology, which is applied in the field of steelmaking, continuous casting and rolling, can solve the problem that local molten steel is not filled and solidified in time, the hook head is not well connected to the slab, and the mold width-thickness ratio is large, etc. The problem is to eliminate the phenomenon of breakout at the start, the filling state of molten steel is good, and the production rhythm is guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

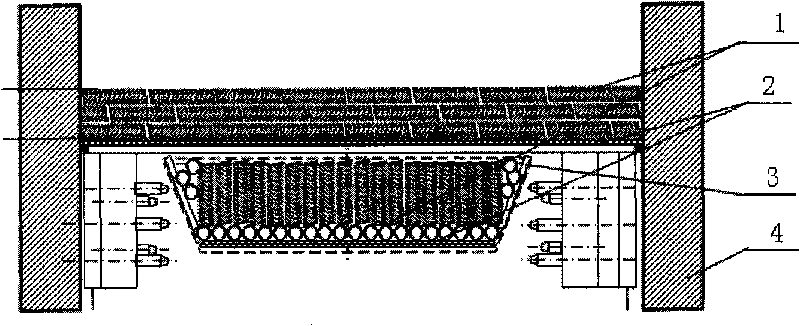

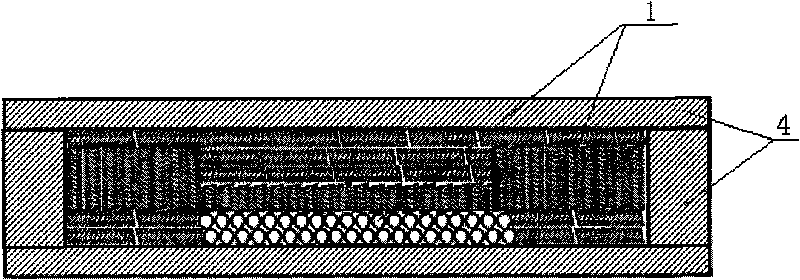

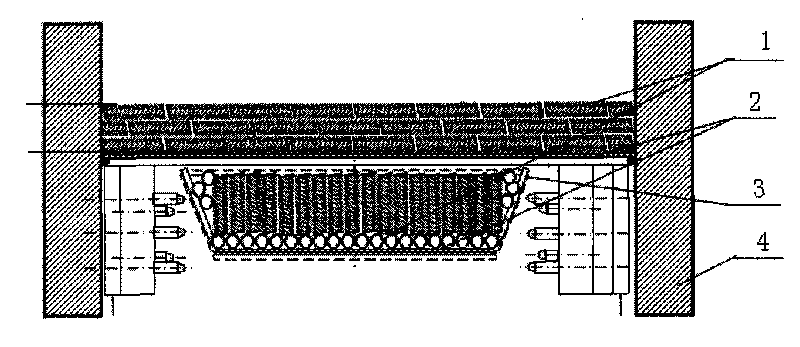

[0016] Specific embodiments of the present invention are described in detail below in conjunction with accompanying drawings,

[0017] like figure 1 As shown, after the crystallizer width is adjusted according to the production plan specifications, the dummy head is blocked according to the following method:

[0018] 1) Adjust the proper position of the dummy head in the crystallizer;

[0019] 2) Use steel brazing to seal the paper rope in the gap between the dummy head and the crystallizer to ensure that the sealing surface and the head of the dummy rod are flat and compact; because the paper rope is easy to carbonize at high temperature, the use of asbestos rope is avoided The phenomenon that the cooling of the slab is affected by the residue or winding of the foot roll;

[0020] 3) Place two thin iron plates 3 on the corner of the hook head to protect the sealing paper rope from directly contacting the molten steel;

[0021] 4) Cover the surroundings of the paper rope wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com