Slab caster two cold nozzle density measuring system

A slab continuous casting machine, water flow density technology, applied in the direction of measuring device, specific gravity measurement, testing of machine/structural components, etc., can solve the problems of high cost, high work intensity, low precision, etc. Precise, short measurement time results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

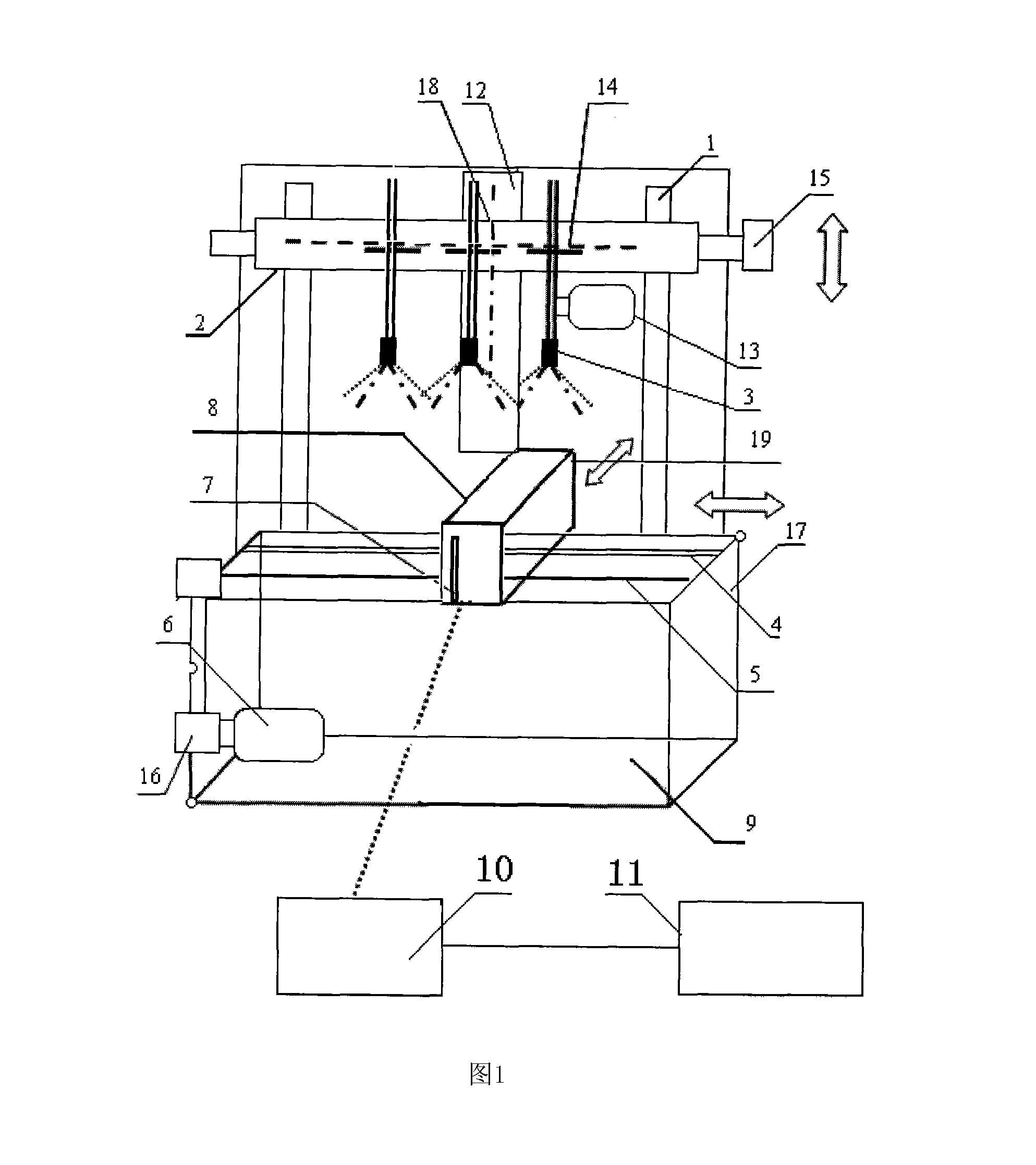

[0017] As shown in Figure 1, it includes a nozzle moving mechanism, a nozzle 3, a signal conditioner 10, a computer data acquisition and analysis unit 11, a water collector 8 and a sensor moving mechanism, and the water collector 8 is fixed on the sensor moving mechanism. The sensor moving mechanism drives the water collector 8 to move to the detection position; the nozzle 3 is fixed on the nozzle moving mechanism, the nozzle 3 is downward, and the nozzle 3 is moved to the top of the water collector 8 through the nozzle moving mechanism, and the bottom of the water collector 8 is installed with liquid The position sensor 7 is driven by the stepper motor 6 to drive the transmission belt 16 and the screw nut 14 to control the water flow density and the water collection unit to move within the spray range of the entire nozzle 3 . When measuring, first move the water collector 8 to the test position, open the cover of the water collector 8, and start collecting water. After a certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com