Method for installing fan-shaped sections of slab continuous casting machine

A slab continuous casting machine and slab continuous casting technology, applied in the field of slab continuous casting, can solve the problems of low arc adjustment accuracy of sector segments, insufficient positioning and accuracy of replacement rails, and inadequate installation, and achieve engineering quality and safety. Reliable, reduced installation engineering cost, scientific effect of installation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

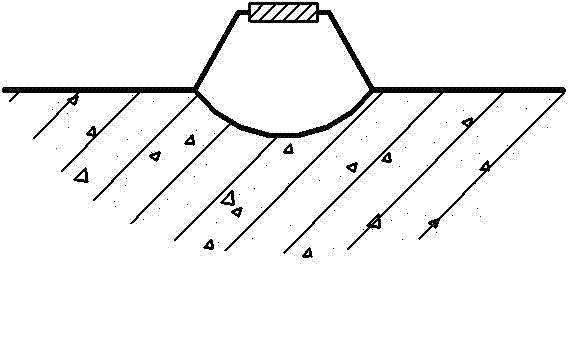

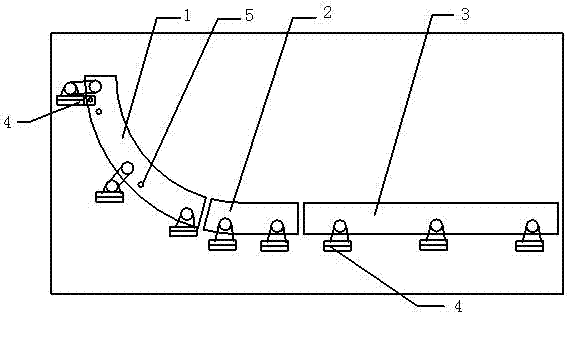

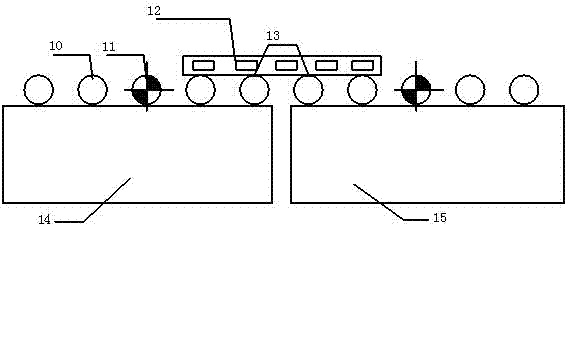

[0050] A method for installing a segment of a slab continuous casting machine, characterized in that it comprises the following steps:

[0051] a. Fundamental acceptance of sector equipment, including the following steps:

[0052] (1) Check and accept the control network, check and accept the control network points in the civil construction area, and set 1 # and 2 # The reference point of the branch track, and make a permanent mark after careful checking;

[0053] (2) For the setting of installation reference line and reference point, take the center line of the continuous casting machine, the outer arc of the casting stream, and the center line of the tangent roll of the tension leveler as the permanent standard plate placed on the foundation, and place it on the casting platform and the rear An elevation reference point is set at the front end of the roller table;

[0054] (3) Basic inspection and acceptance, measuring the overall dimensions, elevation, pit depth of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com