Method for automatically detecting and controlling segment roll gap by adopting balancing oil cylinder

A technology of balancing oil cylinders and automatic detection, applied in the field of production, can solve the problems of large error, insufficient stability, unstable metallurgical effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

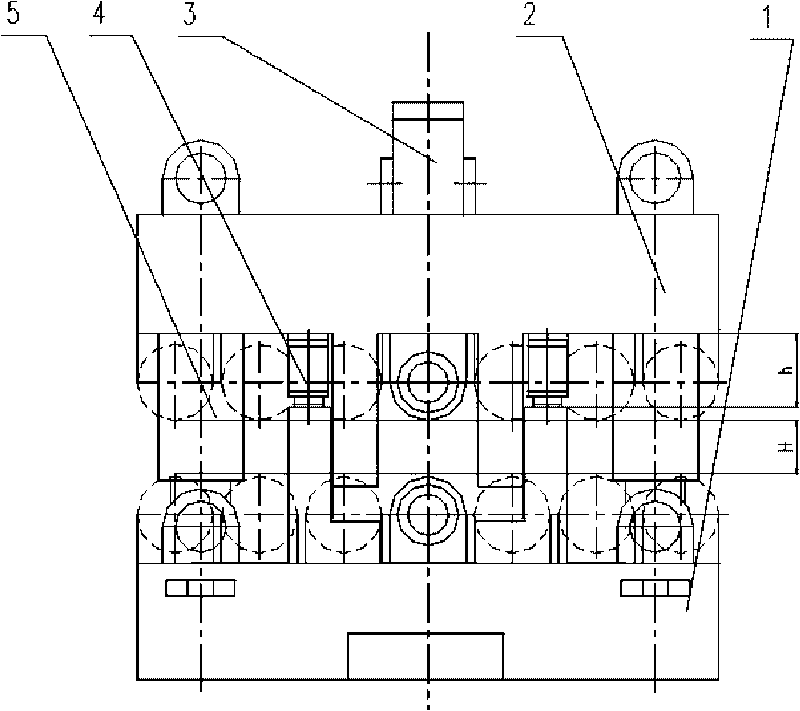

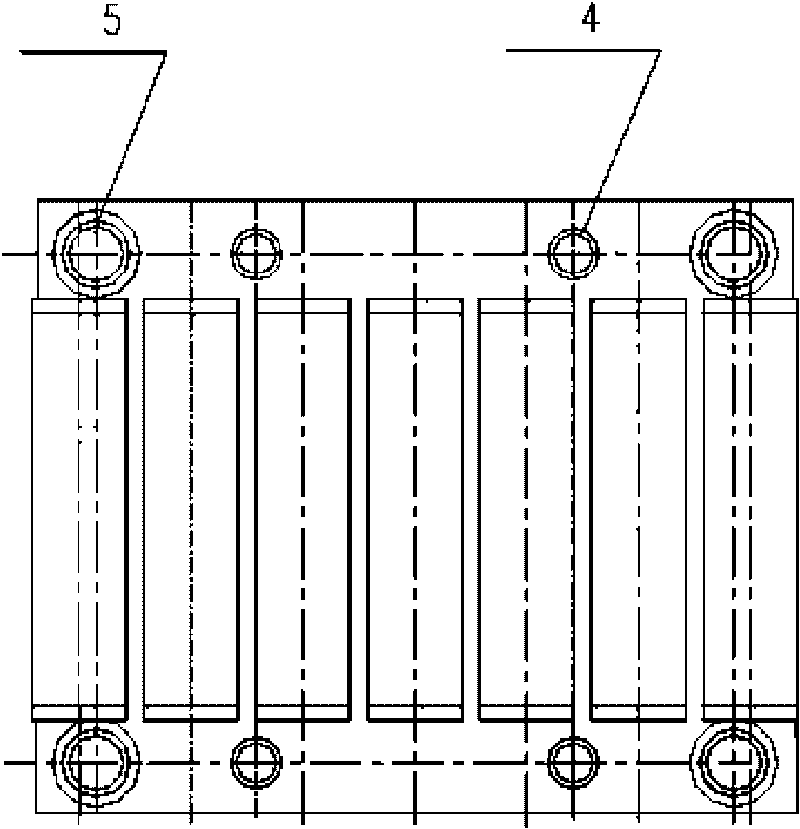

[0014] Such as figure 1 , figure 2 and image 3 As shown, the sector segment used for the arrangement and control of the slab induction roll system in the continuous casting steel production process is the core component of the slab continuous caster, figure 1 It is a schematic diagram of a sector, including the lower frame 1 (outer arc frame) with guide rollers, the upper frame 2 (inner arc frame) with guide rollers, and the depressing roller device 3 for driving the dummy bar and the slab , the balance oil cylinder 4 used for roll gap detection and control and the clamping oil cylinder 5 that connects the upper and lower frames and maintains the roll gap. The pressing roller device 3 is fixed on the upper center of the upper frame 2; the balance oil cylinder 4 is evenly distributed between the upper frame 2 and the lower frame 1.

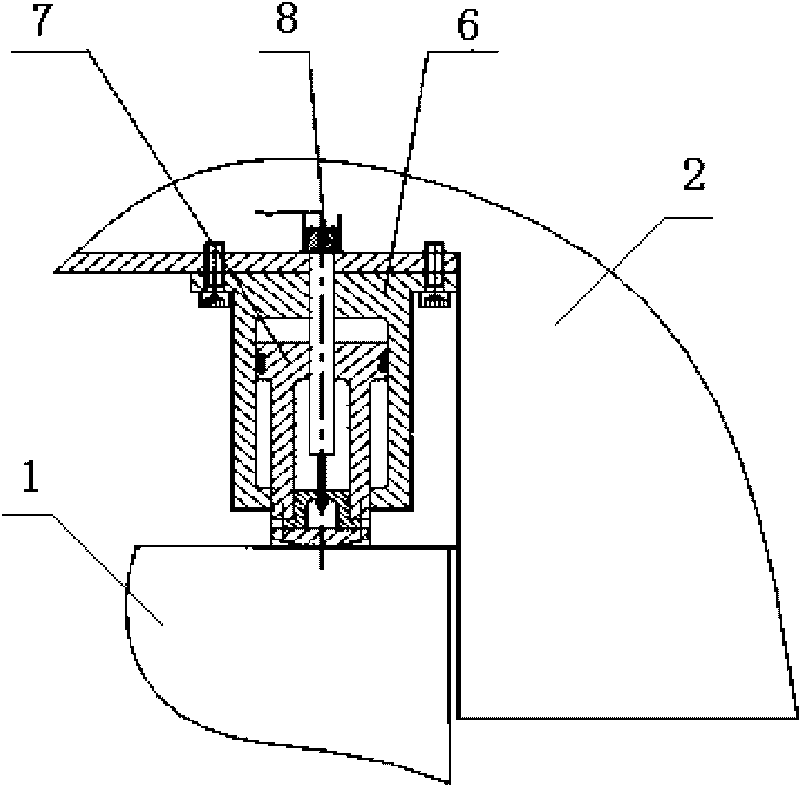

[0015] The balance cylinder 4 adopts a plunger cylinder structure, including the cylinder block 6 and the plunger rod 7 in the cylinder body....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com